Graphene polymer electrochemical sensor, preparation method and application of graphene polymer electrochemical sensor in detection of p-nitrophenol

A p-nitrophenol, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of detection limit, insufficient stability of detection range, difficulty in meeting test requirements, complicated and expensive preparation, etc., and achieve linearity Wide detection range, low detection limit, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

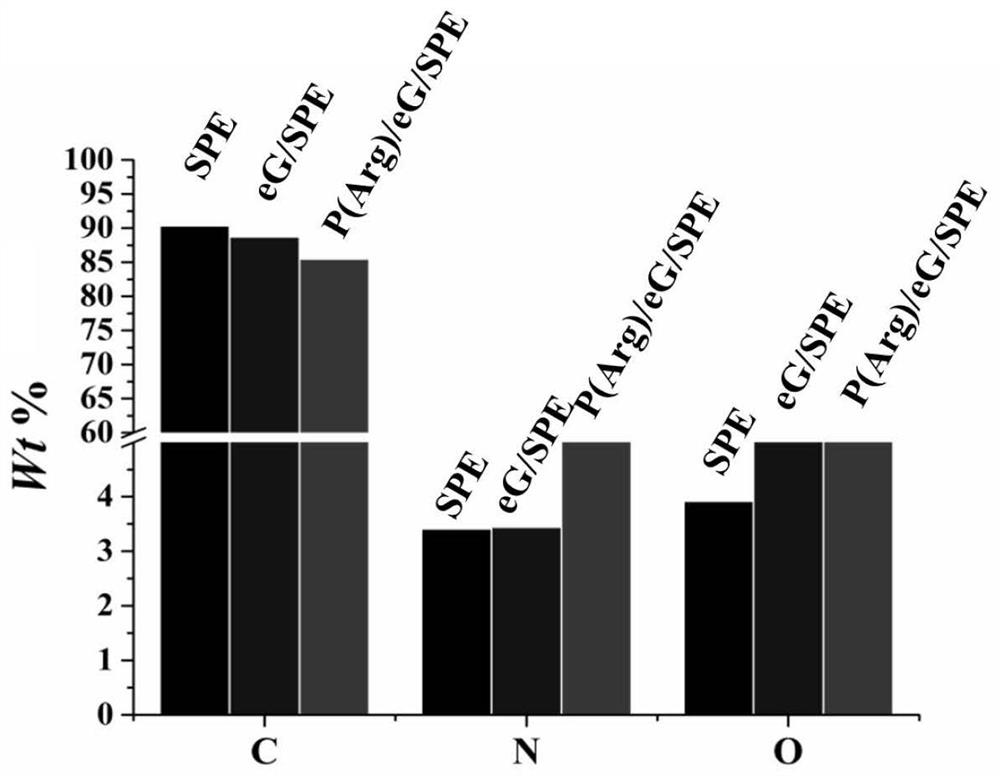

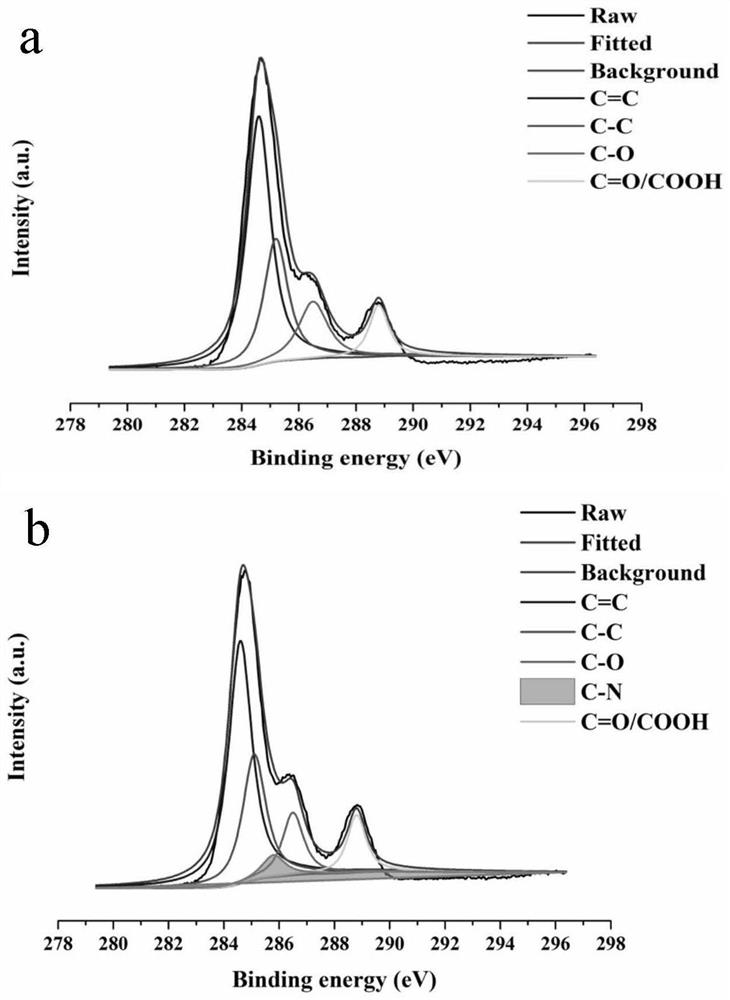

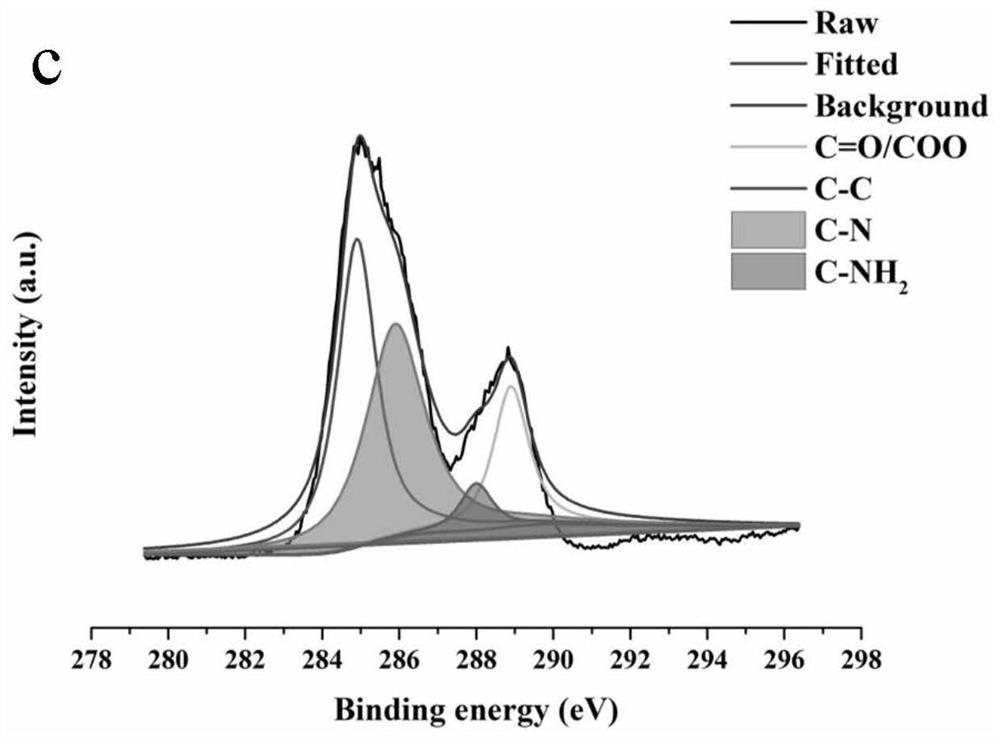

[0052] The carbon electrode of the carbon screen printing electrode (SPE) is used as the working electrode, the carbon counter electrode is used as the counter electrode, and the Ag electrode is used as the reference electrode to form a three-electrode system (C-C-Ag three-electrode), with 0.1M pH 7.0 phosphate Buffer solution (PBS) was used as a supporting electrolyte for electrochemical in situ graphene synthesis.

[0053] Immerse the screen printing under the surface of the supporting electrolyte solution, apply a working voltage of 2.0V to the electrode system through the constant potential mode, and maintain the constant voltage for 200s, take out the working electrode and fully rinse it with deionized water and dry it before use. Then immerse the electrode in the supporting electrolyte solution, perform 20 consecutive scans at -1.5~0V, 100mV / s by cyclic voltammetry, take out the working electrode and fully rinse it with deionized water. Place the electrode in the same PB...

Embodiment 2

[0055] The carbon electrode of the carbon screen printing electrode (SPE) is used as the working electrode, the carbon counter electrode is used as the counter electrode, and the Ag electrode is used as the reference electrode to form a three-electrode system (C-C-Ag three-electrode), with 0.1M pH 7.0 phosphate Buffer solution (PBS) was used as a supporting electrolyte for electrochemical in situ graphene synthesis.

[0056] Immerse the screen printing under the surface of the supporting electrolyte solution, apply a working voltage in the range of 0-2.2V to the electrode system through cyclic voltammetry mode, perform 15 cycles of continuous scanning at a rate of 100mV / s, and take out the working electrode for deionization Rinse thoroughly with water. Then the electrode was immersed in the supported electrolyte solution, and the constant current was placed at -1.8V for continuous treatment for 120s, and the working electrode was taken out and fully rinsed with deionized water...

Embodiment 3

[0058] The carbon electrode of the carbon screen printing electrode (SPE) is used as the working electrode, the carbon counter electrode is used as the counter electrode, and the Ag electrode is used as the reference electrode to form a three-electrode system (C-C-Ag three-electrode), with 0.1M pH 7.0 phosphate Buffer solution (PBS) was used as a supporting electrolyte for electrochemical in situ graphene synthesis.

[0059] Immerse the screen printing under the surface of the supporting electrolyte solution, apply a working voltage of 1.5V to the electrode system through the constant potential mode, and maintain the constant voltage for 240s, take out the working electrode and fully rinse it with deionized water and dry it before use. Then immerse the electrode in the supporting electrolyte solution, perform 25 consecutive scans at -1.5~0V, 120mV / s by cyclic voltammetry, take out the working electrode and fully rinse it with deionized water. Place the electrode in the same PB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com