Low-pressure ammonia synthesis tower and renewable energy low-pressure ammonia synthesis system

A ammonia synthesis tower and ammonia synthesis technology, applied in the direction of energy input, ammonia compound, bulk chemical production, etc., can solve the problems of high operating temperature and pressure, large-scale equipment, complex synthesis route, etc., to achieve sufficient heat exchange and by-product steam The effect of high volume and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

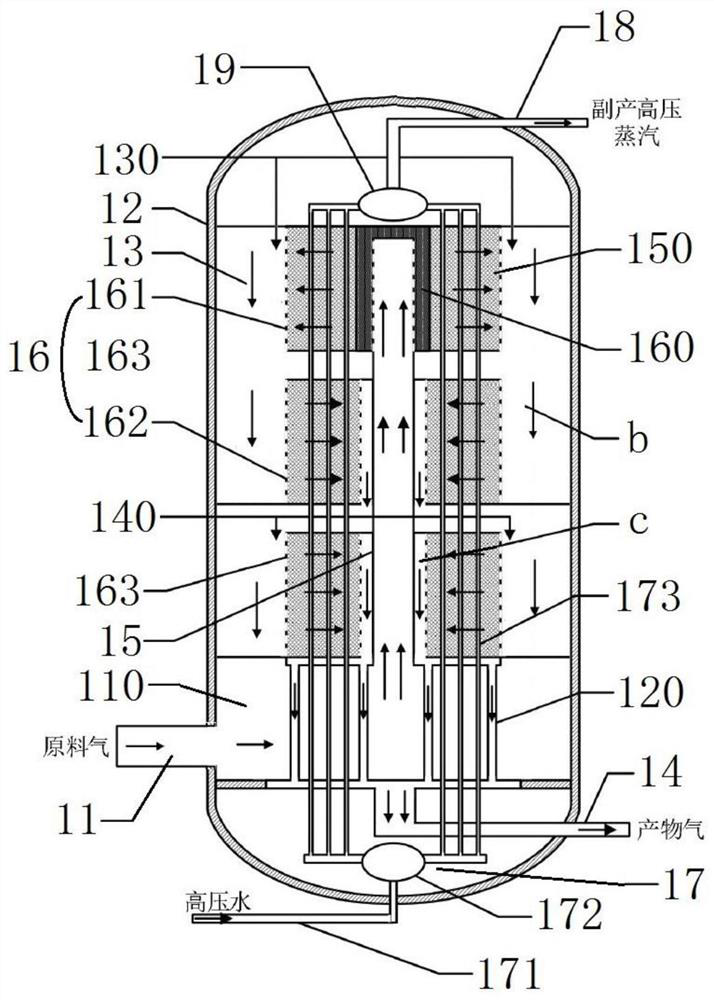

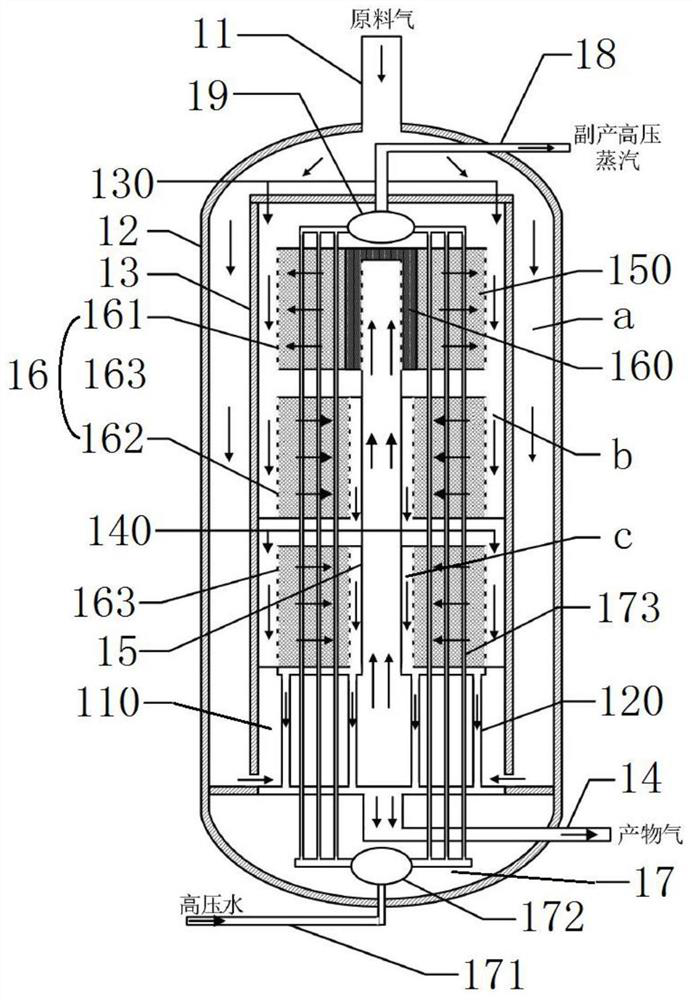

[0067] Ammonia tower level:

[0068] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 10MPa, and the temperature is 25°C;

[0069] The space velocities of the three first catalyst beds from top to bottom are: 10000h -1 、5000h -1 、5000h -1 ;

[0070] The temperature of the catalyst bed is controlled at 400°C;

[0071] The high-pressure water pressure of the water inlet pipe is 11MPa, and the temperature is 25°C;

[0072] The outlet steam temperature of the steam pipe is 320°C;

[0073] The ammonia concentration at the outlet of the product gas outlet pipe is 20.3%.

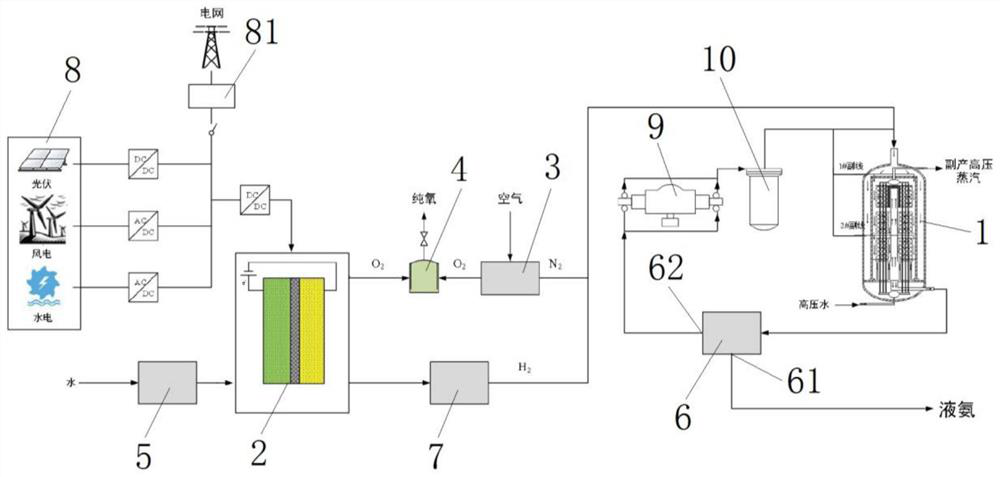

[0074] System technology level:

[0075] In the grid-connected mode, the renewable energy is connected to the grid within the capacity allowed by the grid, and the excess power is used to electrolyze water to produce hydrogen. When the renewable energy power is insufficient, the grid power can also be used to meet basic production needs, es...

Embodiment 2

[0081] Ammonia tower level:

[0082] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 7MPa, and the temperature is 25°C;

[0083] The space velocities of the three first catalyst beds from top to bottom are: 10000h -1 、5000h -1 、5000h -1 ;

[0084] Second catalyst bed space velocity: 15000h -1 ;

[0085] The temperature of the catalyst bed is controlled at 400°C;

[0086] The high-pressure water pressure of the water inlet pipe is 8MPa, and the temperature is 25°C;

[0087] The outlet steam temperature of the steam pipe is 295°C;

[0088] The ammonia concentration at the outlet of the product gas outlet pipe is 16.5%.

[0089] System technology level:

[0090] The working pressure of the electrolyzed water device is 7.5MPa, and the working temperature is 80°C;

[0091] The volume ratio of raw material gas to hydrogen and nitrogen is 2.4:1, and the ratio of raw material gas to recycle gas is 2:5;

...

Embodiment 3

[0095] Ammonia tower level:

[0096] The volume ratio of hydrogen to nitrogen at the inlet of the raw material gas into the pipe is 2.5:1, the pressure is 5MPa, and the temperature is 25°C;

[0097] The space velocities of the three first catalyst beds from top to bottom are: 10000h -1 、5000h -1 、5000h -1 ;

[0098] Second catalyst bed space velocity: 15000h -1 ;

[0099] The temperature of the catalyst bed is controlled at 450°C;

[0100] The high-pressure water pressure of the water inlet pipe is 8MPa, and the temperature is 25°C;

[0101] The steam temperature at the outlet of the steam pipe is 294°C;

[0102] The ammonia concentration at the outlet of the product gas outlet pipe is 14%.

[0103] System technology level:

[0104] The working pressure of the electrolyzed water device is 5.2MPa, and the working temperature is 80°C;

[0105] The volume ratio of raw material gas to hydrogen and nitrogen is 2.2:1, and the ratio of raw material gas to recycle gas is 1:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com