A translucent closed solvent-free epoxy primer compound

A closed, solvent-free technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of poor wetting, poor sealing, sharp increase in cost, and difficult construction, etc., to achieve good film-forming performance, good sealing performance, Effect of High Cost Advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

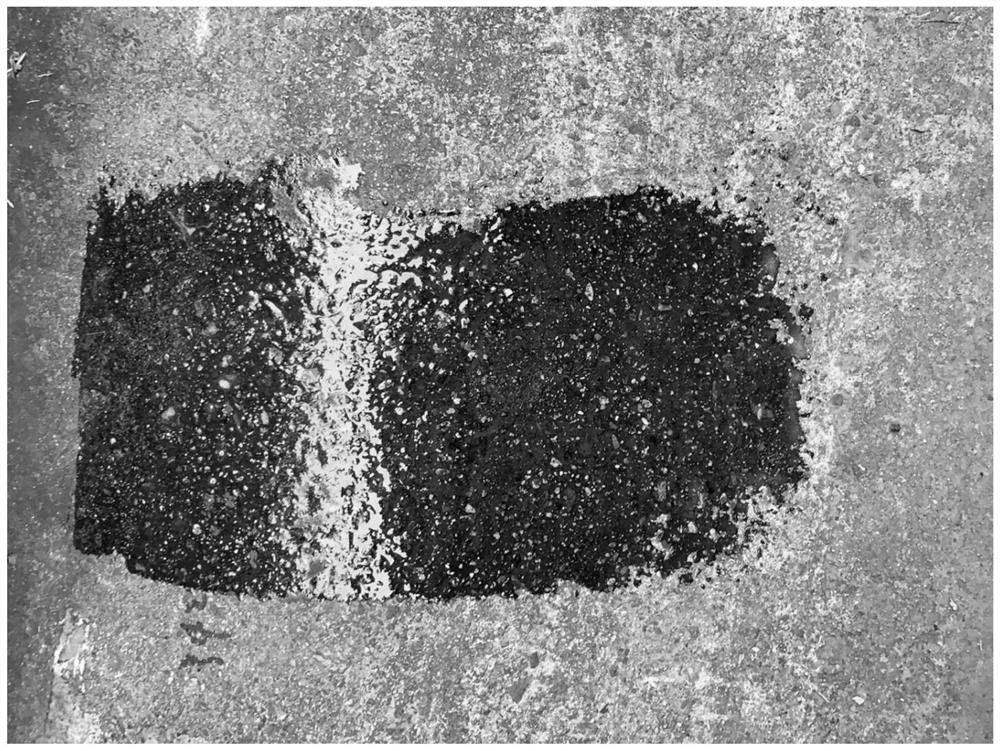

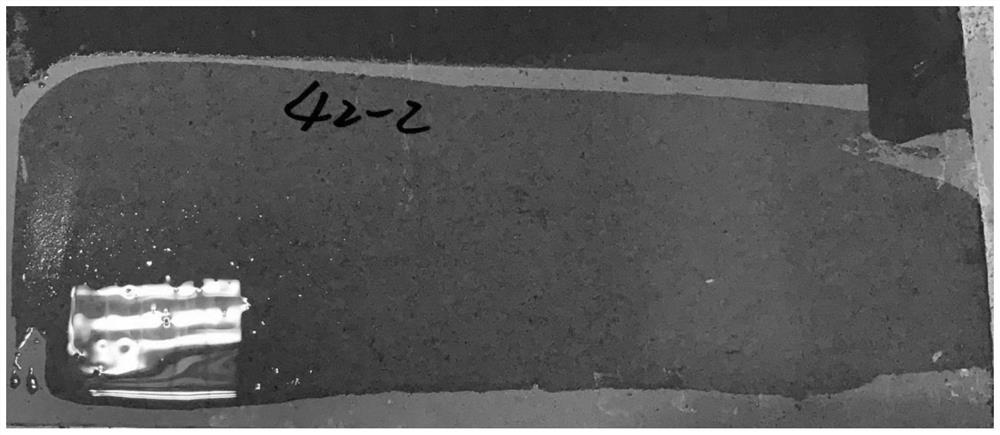

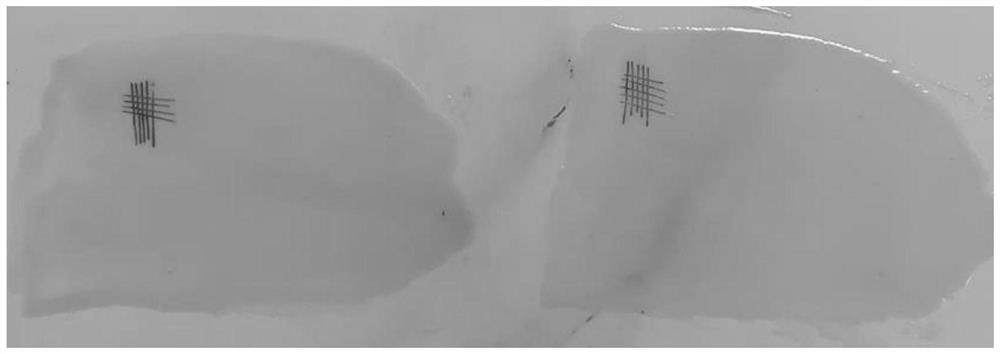

Image

Examples

Embodiment 1

[0035] Preparation of intermediate [a]: Heat 1,4-butanediol diglycidyl ether to 100°C in a reaction kettle, and then put in the same amount of 1,4-butanediol diglycidyl ether under constant stirring Parts by mass of flake, powder or granular E20 bisphenol A epoxy resin is dissolved in 1,4-butanediol diglycidyl ether to form a colorless and transparent homogeneous phase.

[0036] Preparation of component A: Add 26 parts of E51 bisphenol A epoxy resin, 11 parts of 1,4-butanediol diglycidyl ether, and 10 parts of 1 μm (D50) crystalline silica powder to 10 parts of intermediate [a] , 42 parts of 10μm (D50) crystalline silicon powder, 0.3 part of defoamer (BYK-A530); 0.2 part of dispersant (BYK-9011); coupling agent (γ-glycidyl etheroxypropyl trimethoxysilane, KH560 ) 0.5 part, and mix uniformly by high-speed dispersion;

[0037]Preparation of cardanol-modified phenalkamine curing agent: add cardanol in the reaction kettle, add hexamethylenediamine and Aradur 5200 dropwise after h...

Embodiment 2

[0040] Preparation of intermediate [b]: heat neopentyl glycol diglycidyl ether to 100°C in a reaction kettle, and then put in flake, Powdered or granular E20 bisphenol A epoxy resin can be dissolved in neopentyl glycol diglycidyl ether to become a colorless and transparent homogeneous phase.

[0041] Preparation of component A: Add 21 parts of E51 bisphenol F epoxy resin, 11 parts of neopentyl glycol diglycidyl ether, 10 parts of 1.5 μm (D50) crystalline silica powder to 15 parts of intermediate [b], 15 μm (D50) 42 parts of crystalline silicon powder, 0.3 part of defoamer (BYK-A530); 0.2 part of dispersant (BYK-9011); 0.5 part of coupling agent (γ-glycidyl etheroxypropyl trimethoxysilane, KH560) parts, and mix evenly through high-speed dispersion;

[0042] Preparation of cardanol-modified phenalkamine curing agent: add cardanol in the reaction kettle, add ethylenediamine and Aradur 5200 dropwise after the temperature rises to 80-100°C, add paraformaldehyde in batches after th...

Embodiment 3

[0045] Preparation of intermediate [c]: Heat 1,6-hexanediol diglycidyl ether to 100°C in a reaction kettle, and then put in the same amount of 1,6-hexanediol diglycidyl ether under constant stirring The E20 bisphenol A epoxy resin in the form of flakes, powders or granules is dissolved in 1,6-hexanediol diglycidyl ether to form a colorless and transparent homogeneous phase.

[0046] Preparation of component A: Add 24 parts of E54 bisphenol A epoxy resin, 11 parts of 1,6-hexanediol diglycidyl ether, and 10 parts of 1.3 μm (D50) crystalline silicon powder to 12 parts of intermediate [c]. Parts, 13μm (D50) crystalline silicon powder 42 parts, defoamer (BYK-A530) 0.3 part; dispersant (BYK-9011) 0.2 part; coupling agent (γ-glycidyl etheroxypropyltrimethoxysilane, KH560) 0.5 parts, and mix uniformly through high-speed dispersion;

[0047] Preparation of cardanol-modified phenalkamine curing agent: add cardanol in the reaction kettle, add hexamethylenediamine and Aradur 5200 dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com