Vanadium-doped nickel-cobalt double-metal hydroxide electrode material and preparation method thereof

A hydroxide and electrode material technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems that nickel-cobalt double-metal hydroxide materials have not been reported, and achieve uniform size and simple preparation process. , the effect of doping amount controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh 0.105g of nickel nitrate hexahydrate, 0.070g of cobalt nitrate hexahydrate, and 0.114g of urea powder into 60ml of a mixed solvent of methanol and water (the volume ratio of methanol and water is 1:1), and magnetically stir until the solution Clarified to obtain the first solution.

[0026] 2) Add 0.005 g of vanadium chloride into the first solution under ultrasonication or stirring to obtain a clear second solution.

[0027] 3) The second solution was transferred to a reaction kettle with a Teflon lining, and then the whole was placed in an oven, and kept at 150° C. for 12 hours, so as to heat-treat the second solution.

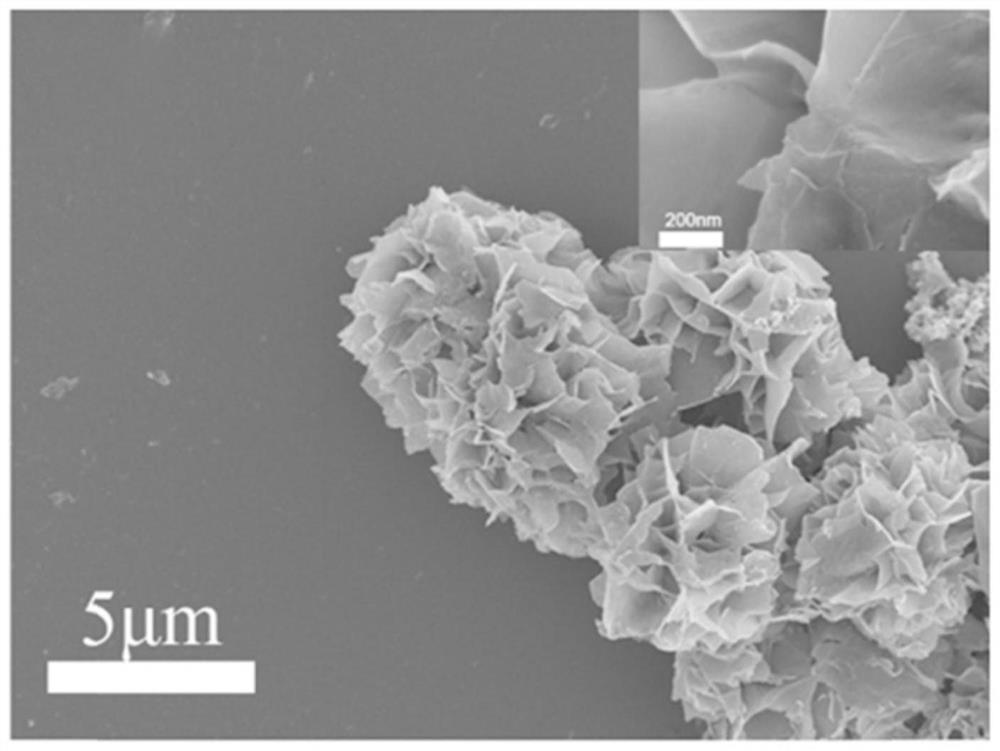

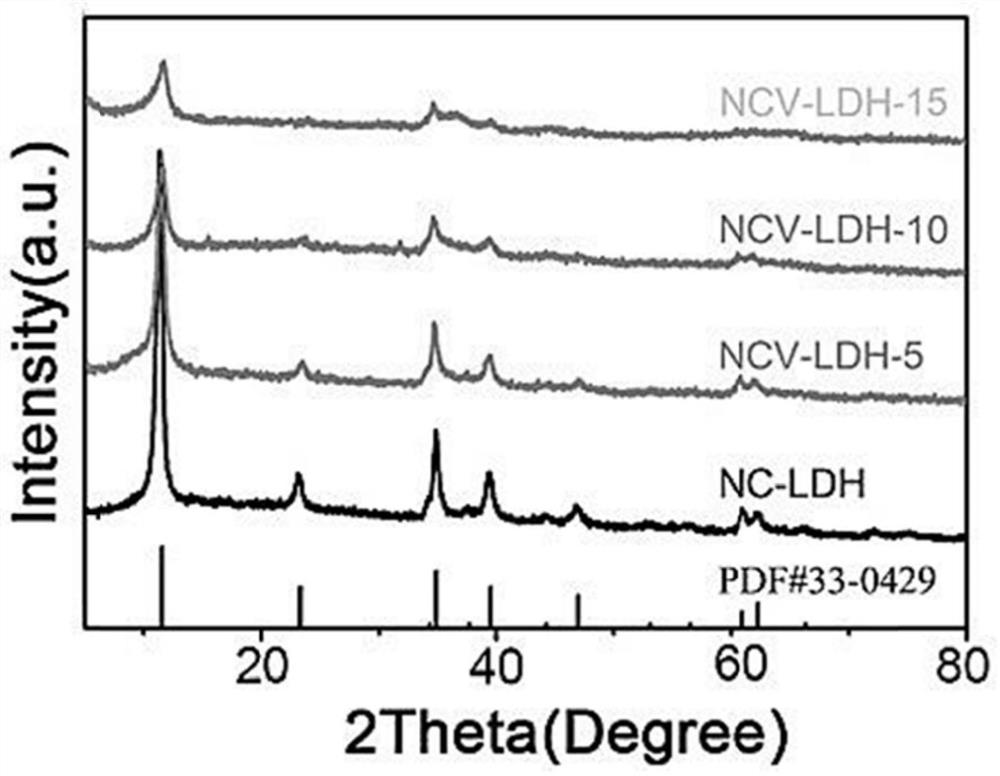

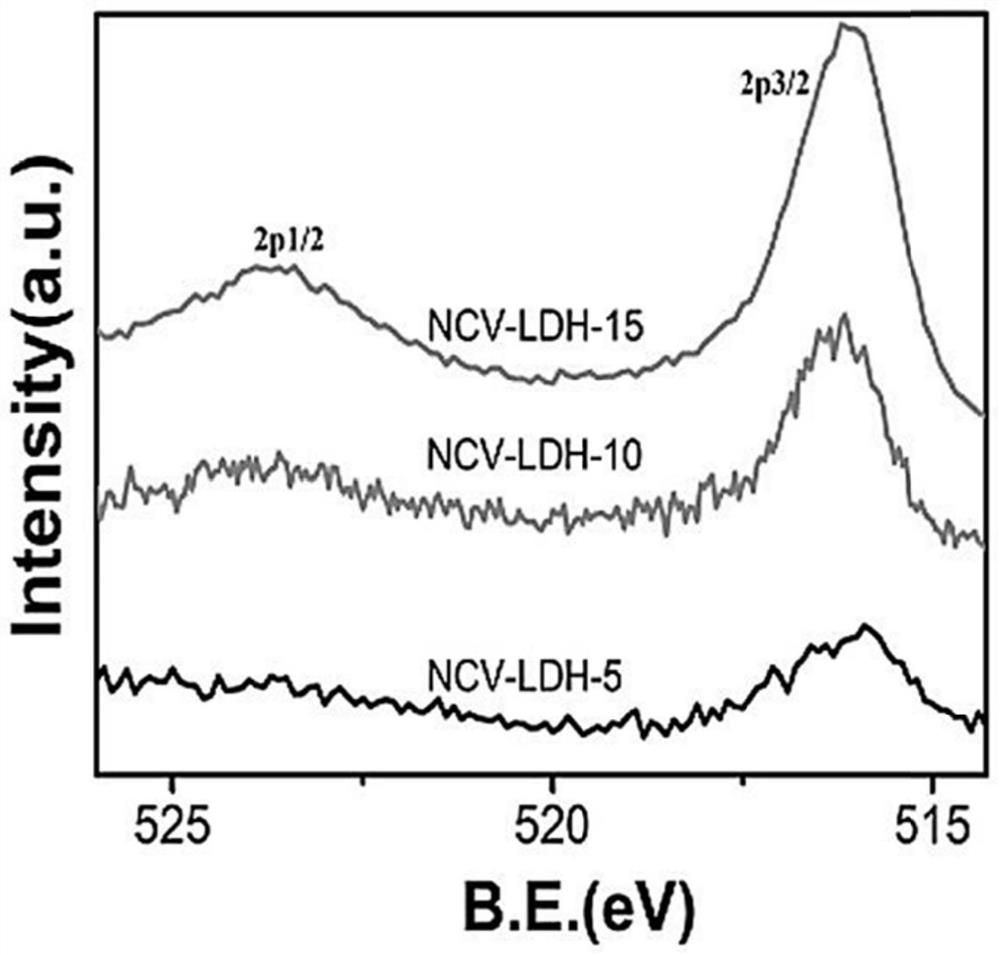

[0028] 4) Cool to room temperature after the heat treatment, centrifuge the reacted second solution to obtain a solid sample, and wash with water and ethanol three times respectively. The washed solid sample was dried in a vacuum oven at 60°C for 24 hours to obtain a vanadium-doped nickel-cobalt double hydroxide electrode material (NCV-LDH-5...

Embodiment 2

[0031] 1) Weigh 0.105g of nickel nitrate hexahydrate, 0.070g of cobalt nitrate hexahydrate, and 0.114g of urea powder into 60ml of a mixed solvent of methanol and water (the volume ratio of methanol and water is 1:1), and magnetically stir until the solution Clarified to obtain the first solution.

[0032] 2) Add 0.010 g of vanadium chloride into the first solution under ultrasound or stirring to obtain a clear second solution.

[0033] 3) The second solution was transferred to a reaction kettle with a Teflon lining, and then the whole was placed in an oven, and kept at 150° C. for 12 hours, so as to heat-treat the second solution.

[0034] 4) Cool to room temperature after the heat treatment, centrifuge the reacted second solution to obtain a solid sample, and wash with water and ethanol three times respectively. The washed solid sample was dried in a vacuum oven at 60°C for 24 hours to obtain a vanadium-doped nickel-cobalt double hydroxide electrode material (NCV-LDH-10). ...

Embodiment 3

[0036] 1) Weigh 0.105g of nickel nitrate hexahydrate, 0.070g of cobalt nitrate hexahydrate, and 0.114g of urea powder into 60ml of a mixed solvent of methanol and water (the volume ratio of methanol and water is 1:1), and magnetically stir until the solution Clarified to obtain the first solution.

[0037] 2) Add 0.015 g of vanadium chloride into the first solution under ultrasonication or stirring to obtain a clear second solution.

[0038] 3) The second solution was transferred to a reaction kettle with a Teflon lining, and then the whole was placed in an oven, and kept at 150° C. for 12 hours, so as to heat-treat the second solution.

[0039] 4) Cool to room temperature after the heat treatment, centrifuge the reacted second solution to obtain a solid sample, and wash with water and ethanol three times respectively. The washed solid sample was dried in a vacuum oven at 60°C for 24 hours to obtain a vanadium-doped nickel-cobalt double hydroxide electrode material (NCV-LDH-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com