High-temperature catalytic filtering material

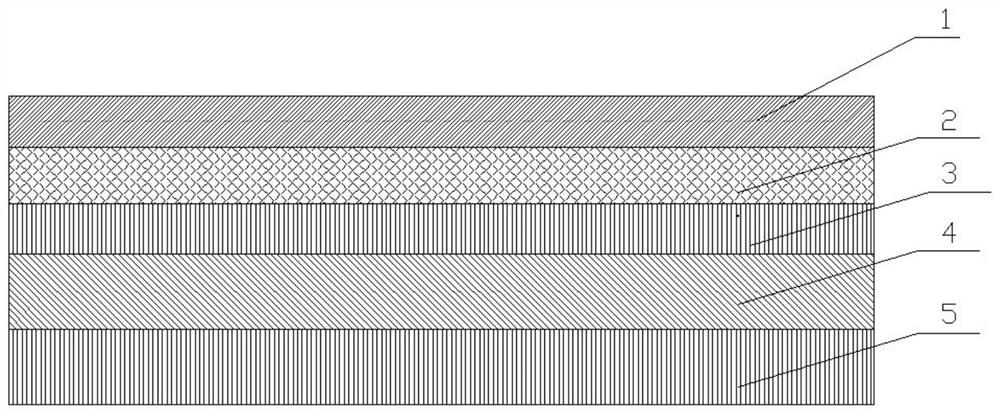

A filter material, high-temperature catalysis technology, applied in filtration and separation, membrane filter, dispersed particle filtration, etc., can solve the problems of weak binding force, poor low-temperature catalytic performance, etc., and achieve long service life, high strength, and high filtration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

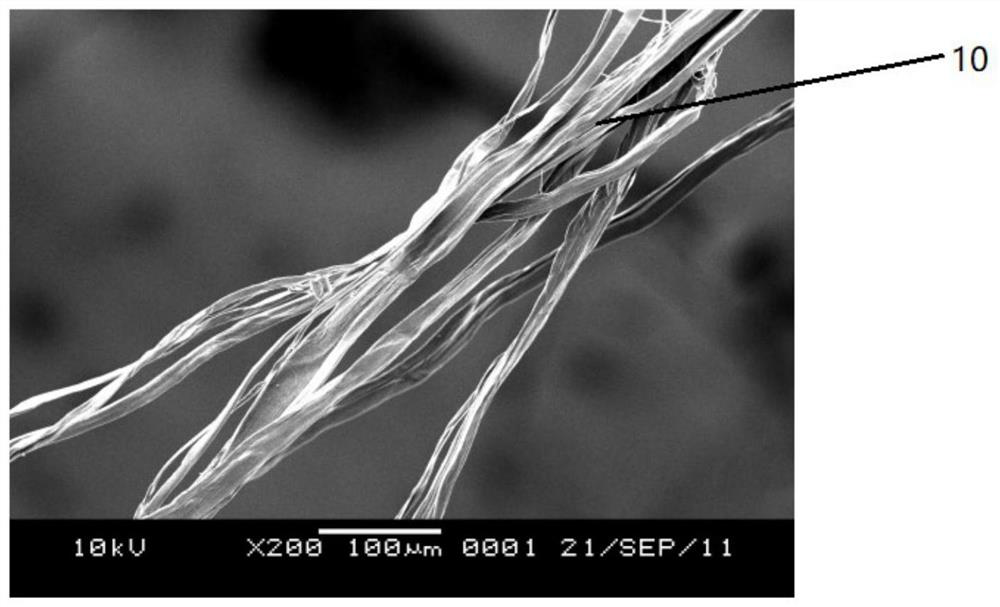

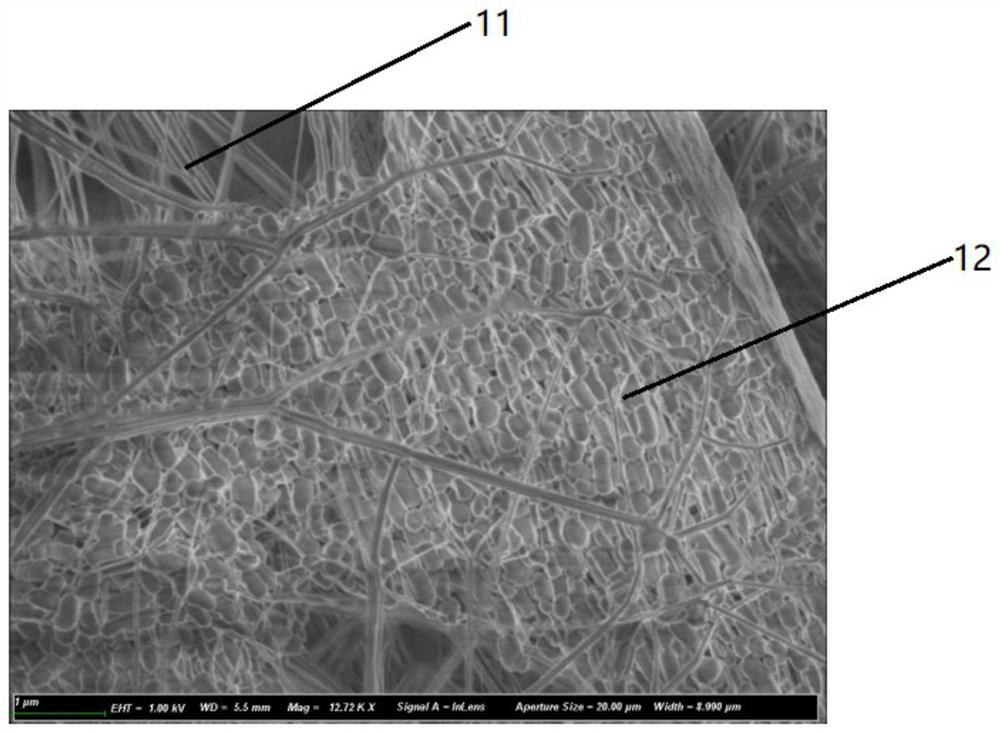

[0032] Embodiment 1: the preparation of the PTFE fiber of supporting catalyst

[0033] With 70% (weight ratio) polytetrafluoroethylene dispersed resin powder, 5% (weight ratio) as shown in table 1 formula catalyst micropowder, 25% (weight ratio) aviation No. 3 kerosene mix, under 10 ℃ of conditions, seal in In the rotating machine, carry out forward rotation 20min, reverse 20min; Then the dispersion liquid of mixed product and 5% (mixed product weight ratio) aviation No. 3 kerosene, 10% (mixed product weight ratio) polytetrafluoroethylene emulsion is at 10 ℃ Sealed in the rotary machine under the condition, rotate forward for 20 minutes and reverse for 20 minutes; then take out the mixture, and mature it at 50°C for 12 hours, so that the polytetrafluoroethylene resin can fully absorb the extrusion aid, so that the performance of the extrudate is consistent; The matured product in the above steps is extruded, extruded by an extruder, and the air in the mixture is removed by pre...

Embodiment 2

[0037] Embodiment 2: the preparation of the PTFE fiber of supporting catalyst

[0038] With 65% (weight ratio) polytetrafluoroethylene dispersed resin powder, 8% (weight ratio) formula catalyst micropowder as shown in table 2, 27% (weight ratio) aviation No. 3 kerosene mix, under 10 ℃ of conditions, seal in In the rotating machine, carry out forward rotation 15min, reverse 15min; Then the dispersion liquid of mixed product and 10% (mixed product weight ratio) aviation No. 3 kerosene, 20% (mixed product weight ratio) polytetrafluoroethylene emulsion is at 10 ℃ Sealed in the rotary machine under the condition, rotate forward for 15 minutes, and reverse for 15 minutes; then take out the mixture, and ripen it at 40°C for 12 hours, so that the polytetrafluoroethylene resin can fully absorb the extrusion aid, so that the performance of the extrudate is consistent; Extruding the matured product in the above steps, extruding through an extruder, pressing to remove the air in the mixtu...

Embodiment 3

[0042] Embodiment 3: the preparation of the PTFE fiber of supporting catalyst

[0043] With 65% (weight ratio) polytetrafluoroethylene dispersed resin powder, 8% (weight ratio) formula catalyst micropowder as shown in table 3, 27% (weight ratio) aviation No. 3 kerosene mix, under 10 ℃ of conditions, seal in In the rotary machine, carry out forward rotation for 15 minutes and reverse rotation for 15 minutes; take out the mixture after the primary mixing, and directly mature it at 40°C for 12 hours without secondary mixing, so that the polytetrafluoroethylene resin can fully absorb the extrusion aid. The performance of the extrudate is consistent; extrude the matured product in the above steps, extrude through the extruder, and press to remove the air in the mixture, so that the particles of the mixture are closely combined and the adhesion between the particles is increased. Force to obtain columnar material, which is convenient for calendering to form a film. The extrusion pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com