Preparation method and application of Ni and Co co-doped carbon-based multifunctional electrocatalyst material

An electrocatalyst and multi-functional technology, applied in the field of energy, can solve the problems of high cost of noble metal-based catalysts, scarcity of resources, and inability to prepare and apply large-scale, to improve mass transfer efficiency and electron transfer efficiency, improve catalytic efficiency, shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

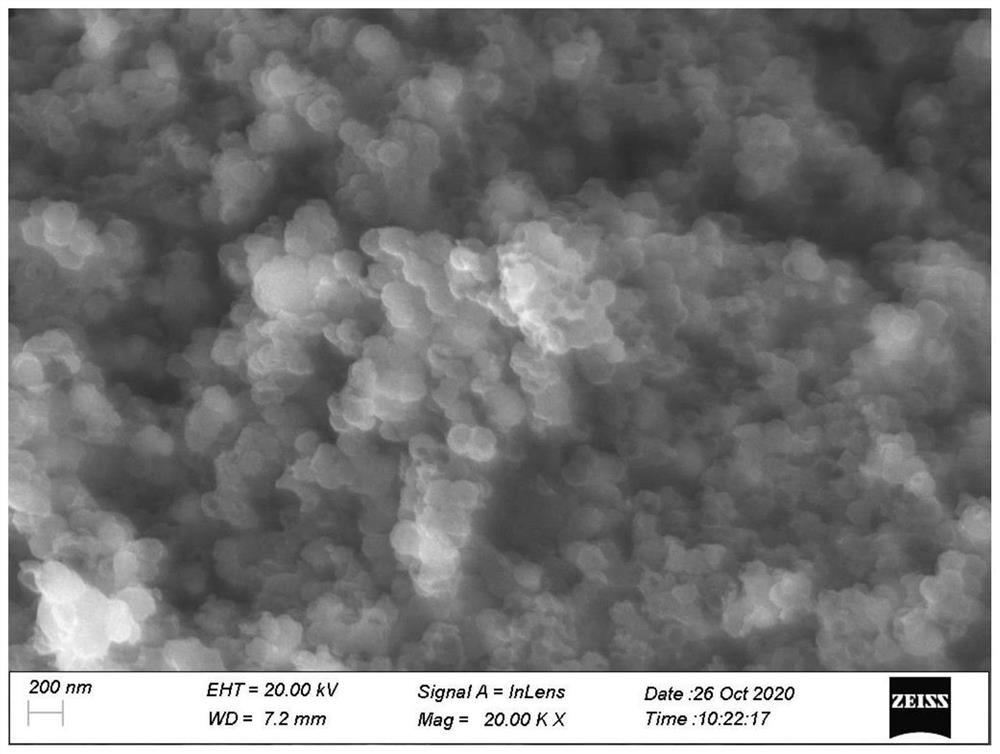

[0035] Step 1: Take styrene: polyvinylpyrrolidone with a mass ratio of 10:1 and dissolve it in 80ml of deionized water, pour it into a three-neck flask and mechanically stir at 300rpm for 30min, during which time high-purity nitrogen gas is continuously introduced to remove air. Then add 0.35g of potassium persulfate dissolved in 20ml of deionized water, and raise the temperature to 70°C, and heat to reflux for 24h. Collect the lotion.

[0036] Step 2: Ultrasonically disperse 0.2 g of the polystyrene microspheres obtained in Step 1 in 30 ml of 0.05 M sulfuric acid solution, add 0.2 ml of aniline and maintain magnetic stirring at 200 rpm for 1 h, then add 20 ml of 0.5 g of ammonium persulfate 0.05M sulfuric acid solution, and keep magnetic stirring at room temperature. After 10 h, it was washed with deionized water and ethanol, and the powder was collected by centrifugation at 9000 rpm and dried.

[0037] Step 3, take 200mg of the powder obtained in step 2 and ultrasonically ...

Embodiment 2

[0040] Step 1: Take styrene: polyvinylpyrrolidone with a mass ratio of 6:1 and dissolve it in 100ml of deionized water, pour it into a three-neck flask and mechanically stir at 380rpm for 30min, during which time high-purity nitrogen gas is continuously introduced to remove air. Then, 0.23 g of potassium persulfate dissolved in 20 ml of deionized water was added, and the temperature was raised to 70° C., and heated to reflux for 12 h. The obtained emulsion was centrifuged at 10000 rpm to collect the emulsion.

[0041] Step 2: Ultrasonically disperse 0.1 g of the polystyrene microspheres obtained in Step 1 in 40 ml of 0.05 M sulfuric acid solution, add 0.1 ml of aniline and maintain magnetic stirring at 200 rpm for 1 h, then add 30 ml of 0.25 g of ammonium persulfate 0.05M sulfuric acid solution, and keep magnetic stirring at room temperature. After 10 h, it was washed with deionized water and ethanol, and the powder was collected by centrifugation at 9000 rpm and dried.

[0...

Embodiment 3

[0045] Step 1: Take styrene: polyvinylpyrrolidone with a mass ratio of 11:1.5 and dissolve it in 80ml of deionized water, pour it into a three-neck flask and mechanically stir at 400rpm for 30min, during which time high-purity nitrogen gas is continuously introduced to remove air. Then, 0.37 g of potassium persulfate dissolved in 20 ml of deionized water was added, and the temperature was raised to 70° C., and heated to reflux for 10 h. The resulting emulsion was centrifuged at 8000 rpm to collect the emulsion.

[0046] Step 2: Ultrasonically disperse 0.2 g of the polystyrene microspheres obtained in Step 1 in 30 ml of 0.05 M sulfuric acid solution, add 0.2 ml of aniline and maintain magnetic stirring at 200 rpm for 1 h, then add 20 ml of 0.5 g of ammonium persulfate 0.05M sulfuric acid solution, and keep magnetic stirring at room temperature. After 12 hours, it was washed with deionized water and ethanol, and the powder was collected by centrifugation at 9000 rpm and dried. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com