Preparation method of copolymerized carbonic ester with improved performance, copolymerized carbonic ester and application of copolymerized carbonic ester

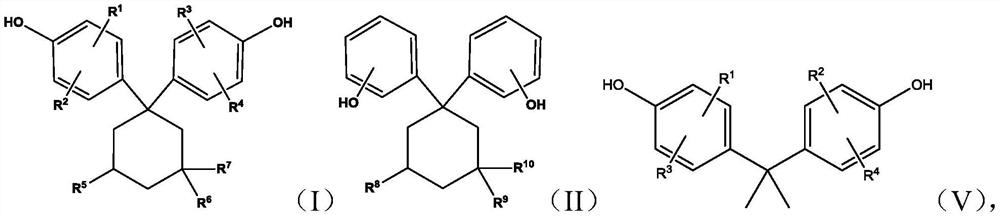

A technology of copolycarbonate and copolycarbonate, which is applied in the preparation of copolycarbonate and the field of copolycarbonate, can solve the problems of slowing down the polycondensation reaction, no obvious improvement in the performance of molded products, and affecting product selectivity, so as to reduce impurities content, avoid surface yellowing, and prevent the effect of sample yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

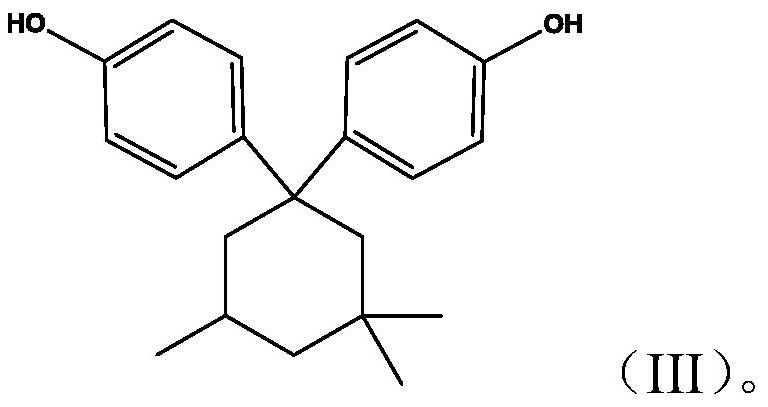

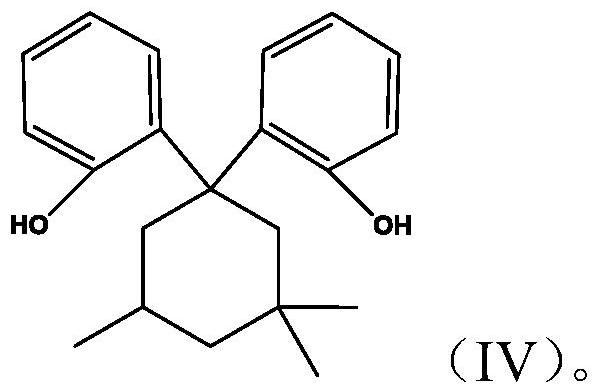

[0062] The raw material BPTMC is synthesized in a laboratory, and the content of the bisphenol compound with the structure of formula (IV) is tested by a liquid chromatograph.

[0063] Preparation method: Take a 5L four-necked flask, weigh 700g (5mol) TMC into it, then add 2350g (25mol) phenol into the four-necked flask, and continuously feed hydrogen chloride gas in a constant temperature water bath at 35°C for reaction. During the reaction, the pH value of the reaction solution was continuously monitored. After about 8 hours of reaction, the introduction of hydrogen chloride gas was stopped, and an appropriate amount of 5% NaOH solution was added into the flask until the pH value of the solution was close to 7.

[0064] Subsequently, the reaction solution was filtered, and the filter cake was weighed. Take a 5L four-neck flask, transfer the filter cake into the bottle, add equal mass of toluene and half mass of pure water, and heat to reflux at 95°C. After about 2 hours of...

Embodiment 1

[0069] Synthesize copolycarbonate prepared by formula (III) and bisphenol A, the molar ratio is 99:1.

[0070] With 306.9g (0.99mol) compound of formula (III), 2.28g (0.01mol) bisphenol A, 222.79g (1.04mol) diphenyl carbonate and 0.01g (2.5 × 10 -4 mol) sodium hydroxide was added to the reactor with a stirring and distillation device, heated to 160°C under normal pressure for 0.5 hours to melt. Then, it heated up to 210 degreeC over 1 hour, and stirred. Then, the pressure was adjusted to 2.5 KPa over 30 minutes, and it was maintained at 210° C. and 2.5 KPa for 30 minutes to conduct a transesterification reaction. Then the temperature was raised to 270° C. at a rate of 30° C. / hour, and kept at 270° C. and 2.5 KPa for 30 minutes. Then, it adjusted to 1KPa over 10 minutes, and held at 270 degreeC and 1KPa for 1 hour. It took 30 minutes to reduce the pressure to below 133 Pa, and stirred for 20 minutes under the conditions of 270° C. and below 133 Pa to carry out the polymeriza...

Embodiment 2

[0073] Synthesize copolycarbonate prepared by formula (III) and bisphenol A, the molar ratio is 99:1.

[0074] Refer to Example 1 for monomer content and synthesis steps to synthesize a copolycarbonate resin, number A2, with a weight average molecular weight of 32325.

[0075] Among them, in the bisphenol compound with the structure of formula (III), the content of formula (IV) is 452ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com