Novel fluorine material high-temperature-resistant control cable material and preparation method thereof

A technology for controlling cables and fluorine materials, which is applied to circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of difficult production process of fluoroplastic cables, the performance of fluoroplastics needs to be improved, and the high price of fluoroplastic raw materials to achieve loss The effect of low cost, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

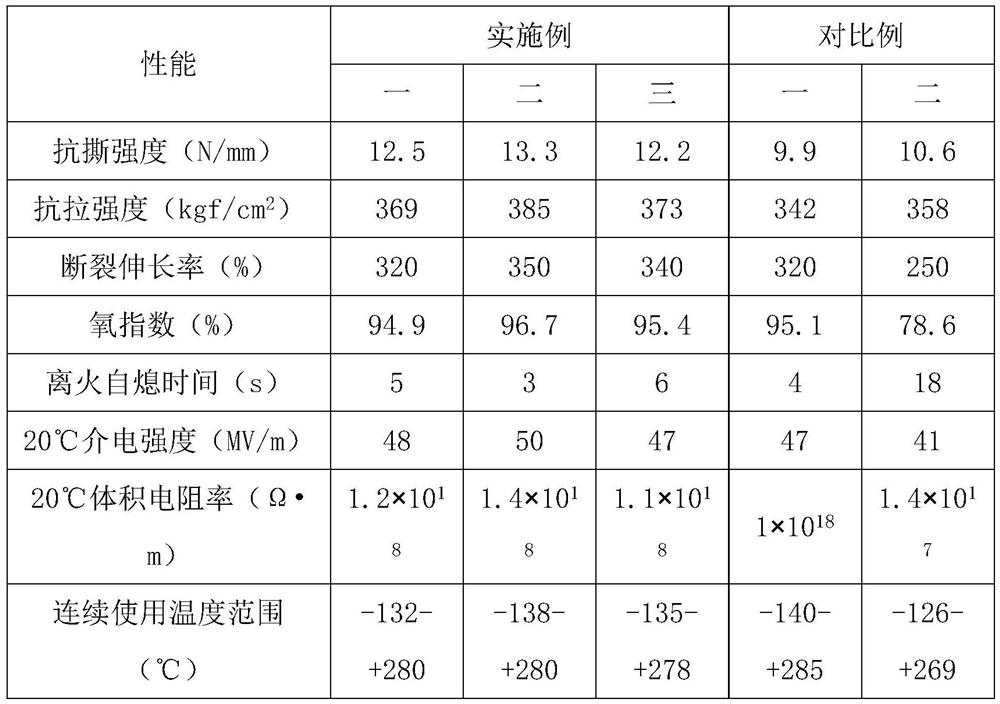

Examples

Embodiment 1

[0026] A novel fluorine material high temperature resistant control cable material proposed by the present invention comprises the following raw materials in parts by weight: 30 parts of new fluorine material, 25 parts of silicone rubber, methyl vinyl dimethyl (siloxane and polysiloxane) 8 parts, 1 part of zinc dibenzyl dithiocarbamate, 3 parts of methyl silicone oil, 10 parts of filler, 2 parts of stabilizer;

[0027] The filler is nano-kaolin and nano-titanium dioxide;

[0028] The stabilizer is obtained by compounding calcium stearate, dioctyltin dilaurate, 1,6-hexanediol diacrylate and ethylene glycol in a mass ratio of 1:1:3:7;

[0029] The novel fluorine material is prepared by the following method:

[0030] (1) Under vacuum conditions, the mixed reaction raw materials triphenylchloromethane and 4-methyldiphenylchloromethane are jointly added to the reactor at a mass ratio of 4:1, and the temperature is raised to 85°C, and the mass ratio is 32:45 : 1, add anhydrous hyd...

Embodiment 2

[0038]A novel fluorine material high temperature resistant control cable material proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of new fluorine material, 30 parts of silicone rubber, methyl vinyl dimethyl (siloxane and polysiloxane) 10 parts, 2.5 parts of zinc dibenzyl dithiocarbamate, 4 parts of methyl silicone oil, 12 parts of filler, 2.5 parts of stabilizer;

[0039] Described filler is nano magnesium oxide and nano talcum powder;

[0040] The stabilizer is obtained by compounding calcium stearate, dioctyltin dilaurate, 1,6-hexanediol diacrylate and ethylene glycol in a mass ratio of 1:1:2:5;

[0041] The novel fluorine material is prepared by the following method:

[0042] (1) Under vacuum conditions, the mixed reaction raw materials triphenylchloromethane and 4-methyldiphenylchloromethane are jointly added to the reactor at a mass ratio of 5:1, and the temperature is raised to 90°C, and the mass ratio is 36:50 : 1, ...

Embodiment 3

[0050] A novel fluorine material high temperature resistant control cable material proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of new fluorine material, 35 parts of silicone rubber, methyl vinyl dimethyl (siloxane and polysiloxane) 12 parts, 4 parts of zinc dibenzyl dithiocarbamate, 5 parts of methyl silicone oil, 15 parts of filler, 3 parts of stabilizer;

[0051] Described filler is nano-calcium carbonate and nano-silicon dioxide;

[0052] The stabilizer is obtained by compounding calcium stearate, dioctyltin dilaurate, 1,6-hexanediol diacrylate and ethylene glycol in a mass ratio of 3:3:5:11;

[0053] The novel fluorine material is prepared by the following method:

[0054] (1) Under vacuum conditions, the mixed reaction raw materials triphenylchloromethane and 4-methyldiphenylchloromethane are jointly added to the reactor at a mass ratio of 7:2, and the temperature is raised to 95°C, and the mass ratio is 40:55 : 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com