Biomass flame retardant, water-based flame-retardant coating as well as preparation method and application of water-based flame-retardant coating

A technology for flame retardant coatings and flame retardants, applied in the field of flame retardant materials, can solve the problems that the use requirements of flame retardant coatings cannot be met, and the efficiency of bio-based flame retardants is low, achieving good flame retardant protection, convenient processing, and adding small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

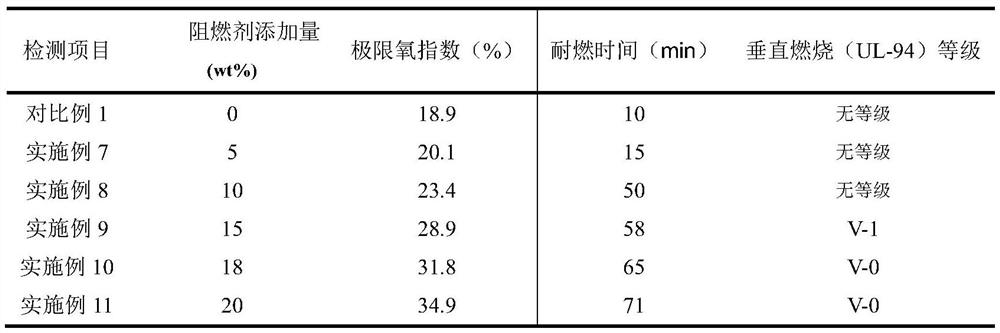

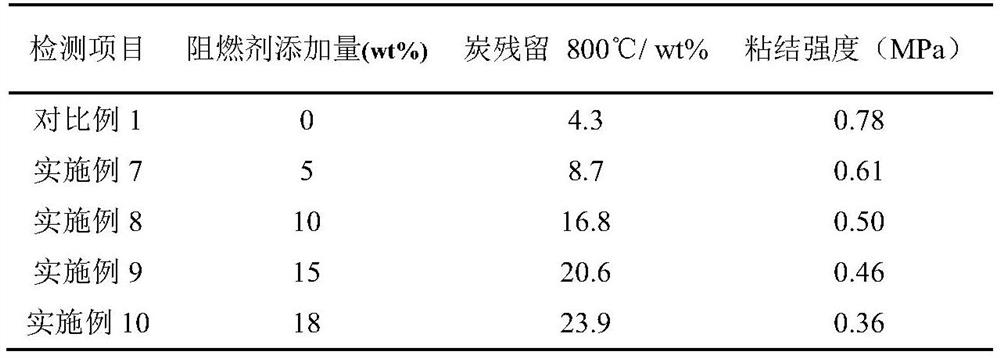

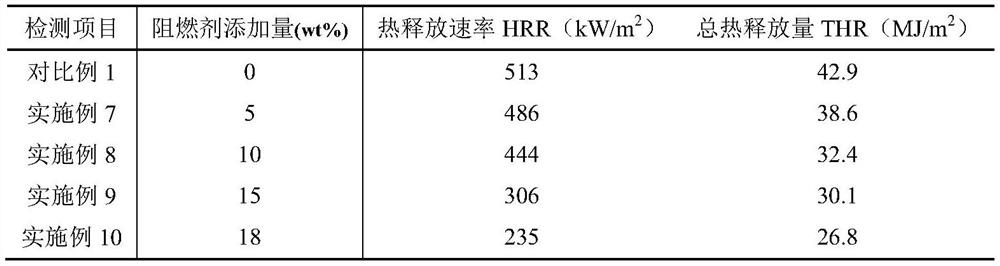

Examples

Embodiment 1

[0025] The present embodiment provides a kind of biomass flame retardant, and main component comprises chitosan, melamine formaldehyde resin coating ammonium polyphosphate MFAPP and flame retardant synergist micron organic montmorillonite OMMT; Wherein chitosan and MFAPP The weight ratio is 1:1, and the weight of the micron organic montmorillonite accounts for 4% of the total weight of the biomass flame retardant.

[0026] In this embodiment, the degree of deacetylation of chitosan is greater than 95%, and there is no molecular weight requirement. Micron organic montmorillonite particle size requires D50<40μm.

[0027] The preparation method of MFAPP in the present embodiment comprises the following steps:

[0028] Step 1, preparation of melamine formaldehyde prepolymer:

[0029] Mix melamine and formaldehyde at a mass ratio of 1:3, adjust the pH of the system to 7 with sodium hydroxide, and then react in a constant temperature water bath at 65°C for 3 hours to obtain a mela...

Embodiment 2

[0034] The present embodiment provides a kind of biomass flame retardant, and main component comprises chitosan, melamine formaldehyde resin coating ammonium polyphosphate MFAPP and flame retardant synergist micron organic montmorillonite OMMT; Wherein chitosan and MFAPP The weight ratio is 1:2, and the weight of the micron organic montmorillonite accounts for 6% of the total weight of the biomass flame retardant.

[0035] In this embodiment, the degree of deacetylation of chitosan is greater than 95%, and there is no molecular weight requirement. Micron organic montmorillonite particle size requires D50<40μm.

[0036] The preparation method of MFAPP in the present embodiment comprises the following steps:

[0037] Step 1, preparation of melamine formaldehyde prepolymer:

[0038] Mix melamine and formaldehyde at a mass ratio of 1:3, adjust the pH of the system to 8 with sodium hydroxide, and then react in a constant temperature water bath at 70°C for 3 hours to obtain a mela...

Embodiment 3

[0043] The present embodiment provides a kind of biomass flame retardant, and main component comprises chitosan, melamine formaldehyde resin coating ammonium polyphosphate MFAPP and flame retardant synergist micron organic montmorillonite OMMT; Wherein chitosan and MFAPP The weight ratio is 1:3, and the weight of the micron organic montmorillonite accounts for 8% of the total weight of the biomass flame retardant.

[0044] In this embodiment, the degree of deacetylation of chitosan is greater than 95%, and there is no molecular weight requirement. Micron organic montmorillonite particle size requires D50<40μm.

[0045] The preparation method of MFAPP in the present embodiment comprises the following steps:

[0046] Step 1, preparation of melamine formaldehyde prepolymer:

[0047] Mix melamine and formaldehyde at a mass ratio of 1:3, adjust the pH of the system to 9 with sodium hydroxide, and then react in a constant temperature water bath at 75°C for 3 hours to obtain a mela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com