High-flux super-hydrophobic wood as well as preparation method and application thereof

A super-hydrophobic, high-throughput technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome preparation of super-hydrophobic materials, non-renewable materials, and low separation efficiency, and achieve low equipment requirements , application operation is simple, the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, set the density to 120kg / m 3 Put the wood into a mixed solution of 25mol / L sodium hydroxide and 5mol / L sodium sulfite, that is, the mass ratio of sodium hydroxide to sodium sulfite is 5:1, then place it in an oil bath and heat it at 100°C for 8h, take it out and wash it with clean water Wash three times; then, put the wood in a 25mol / L hydrogen peroxide solution, heat it in an oil bath at 100°C for 0.5h, take it out and wash it three times with clean water, then put the wood in the refrigerator to freeze for 10h, Then put it in a freeze-drying box for 6 hours; finally, use tetrahydrofuran as a solvent to prepare a 10wt% polydimethylsiloxane solution, then put it into the above wood, take it out and cure it at 100°C for 3 hours, and then obtain a high-throughput superhydrophobic wood.

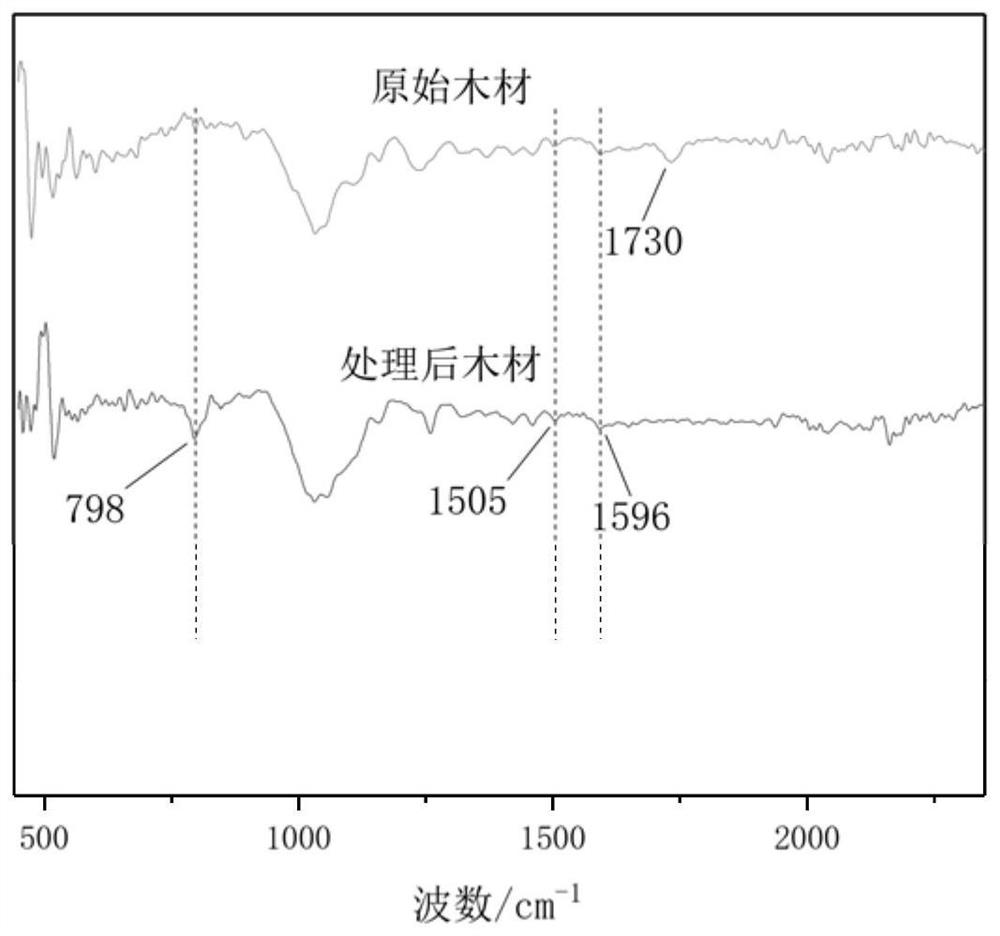

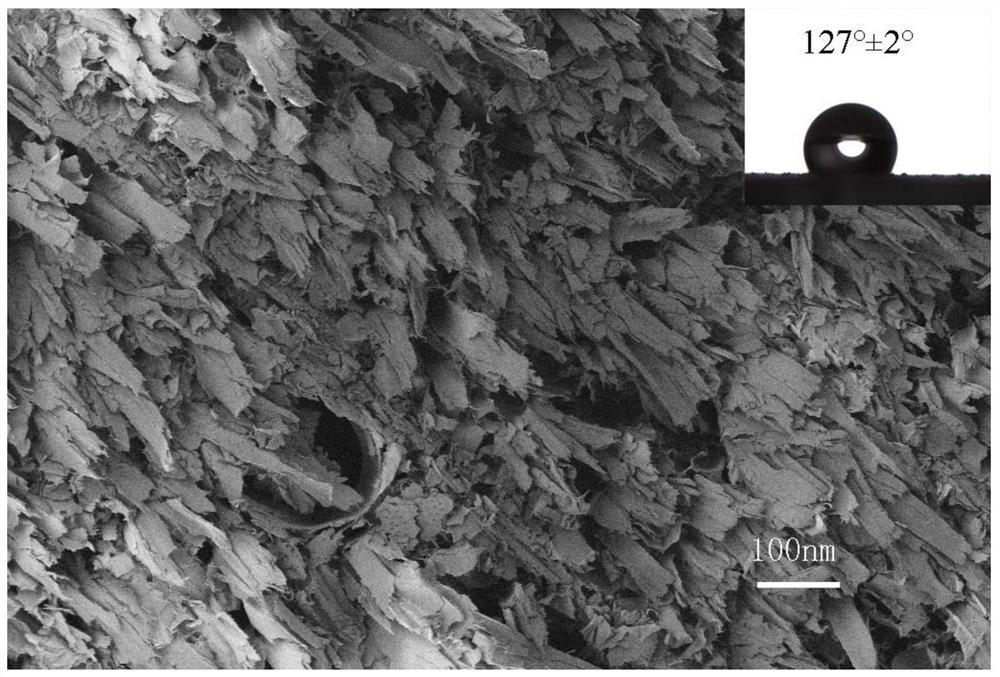

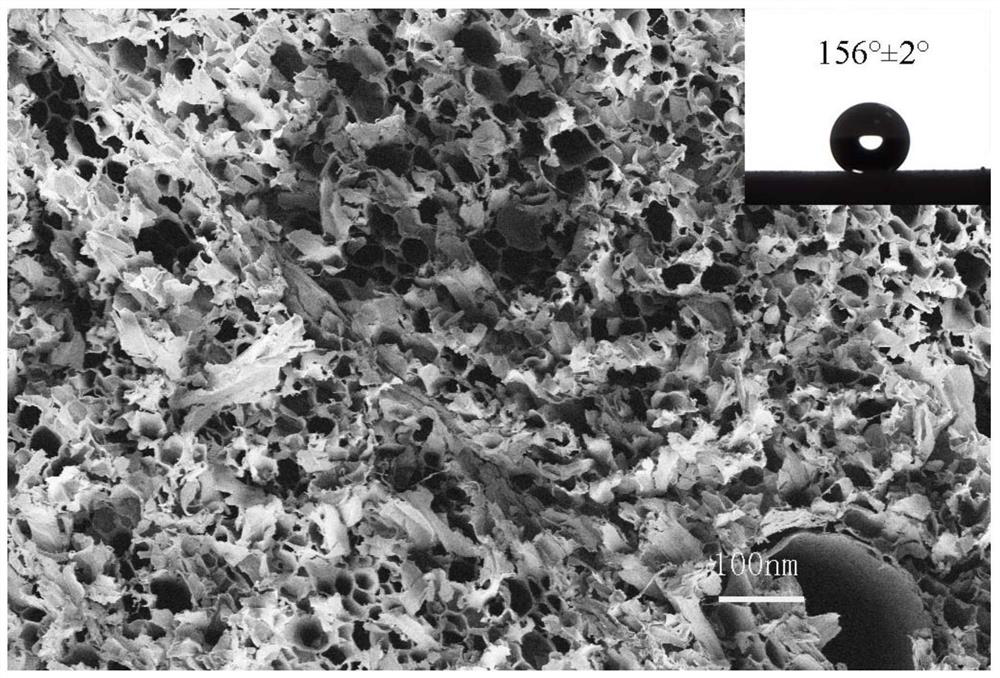

[0028] figure 1 Infrared spectra of the high-throughput superhydrophobic wood prepared in Example 1 and the original wood. Compared with the original wood, superhydrophobic wood...

Embodiment 2

[0032] First, set the density to 140kg / m 3 Put the wood into a mixed solution of 20mol / L sodium hydroxide and 5mol / L sodium sulfite, that is, the mass ratio of sodium hydroxide to sodium sulfite is 4:1, then place it in an oil bath and heat it at 100°C for 7h, take it out and wash it with clean water Wash three times; then, put the wood in a 20mol / L hydrogen peroxide solution, heat it in an oil bath at 100°C for 1 hour, take it out and wash it three times with water, put the wood in the refrigerator to freeze for 10 hours, and then Put it in a freeze-drying box for 5 hours; finally, use acetone as a solvent to prepare a 5wt% polydimethylsiloxane solution, then put the above wood, take it out and cure it at 90°C for 3 hours, and then the high-throughput superhydrophobic wood is obtained. .

[0033] Use a contact angle measuring instrument to measure the contact angle of superhydrophobic wood, and the available contact angle is 154 °, and the experiment is carried out according...

Embodiment 3

[0035] First, set the density to 150kg / m 3 Put the wood into a mixed solution of 10mol / L sodium hydroxide and 10mol / L sodium sulfite, that is, the mass ratio of sodium hydroxide to sodium sulfite is 1:1, then place it in an oil bath and heat it at 100°C for 10h, take it out and wash it with clean water Wash three times; then, put the wood in a 15mol / L hydrogen peroxide solution, heat it in an oil bath at 100°C for 1.5 hours, take it out and wash it three times with clean water, and then put the wood in the refrigerator to freeze for 10 hours. Then put it in a freeze-drying box for 8 hours; finally, use toluene as a solvent to prepare a 2wt% polydimethylsiloxane solution, put it into the above wood, take it out and cure it at 80°C for 6 hours, and then obtain a high-flux superhydrophobic wood.

[0036] Use a contact angle measuring instrument to measure the contact angle of superhydrophobic wood, and the available contact angle is 155°, and the experiment is carried out accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation flux | aaaaa | aaaaa |

| Separation flux | aaaaa | aaaaa |

| Separation flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com