Waterproof leaking stoppage material for civil building materials and processing method thereof

A material processing and waterproof plugging technology, applied in the direction of chloroprene homopolymer coatings, coatings, etc., can solve the problems of poor waterproof and leakage resistance, and waterproof plugging materials are prone to thermal expansion and freezing expansion, etc., to achieve excellent waterproofing , enhance the tensile strength and impermeability, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

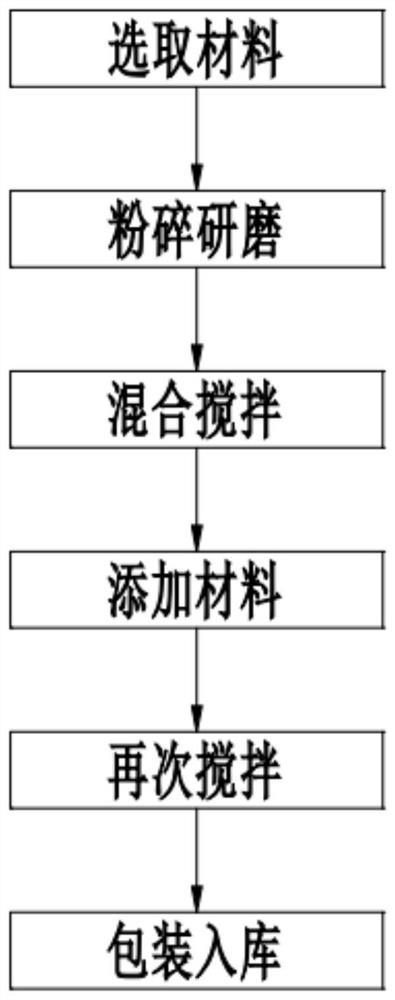

[0050] A method for processing a waterproof plugging material for civil building materials, comprising the following steps:

[0051] S1. Selection of materials: Select the following materials from the market: 50 parts of cationic neoprene emulsion, 2 parts of chemical root inhibitor, 30 parts of calcined ceramic powder, 2 parts of hydroxide solution, 4 parts of nano additives, 4 parts of thickener , 12 parts of reinforcing fiber, 6 parts of antifreeze, 15 parts of calcium powder, 20 parts of water;

[0052] S2. Crushing and grinding: Pour the calcined ceramic powder and reinforcing fiber into a pulverizer or grinder for grinding and grinding, and remove large solid particles in the material;

[0053] S3. Mixing and stirring: Pour the ground material, solution and water in the previous step into different mixing equipment for stirring according to requirements. At this time, when stirring and mixing, add calcined ceramic powder, nano-additives, and water into the same mixer and...

Embodiment 2

[0058] A method for processing a waterproof plugging material for civil building materials, comprising the following steps:

[0059] S1. Selection of materials: Select the following materials from the market: 50 parts of cationic neoprene emulsion, 2 parts of chemical root inhibitor, 20 parts of calcined ceramic powder, 2 parts of hydroxide solution, 4 parts of nano additives, 4 parts of thickener , 12 parts of reinforcing fiber, 6 parts of antifreeze, 15 parts of calcium powder, 20 parts of water;

[0060] S2. Crushing and grinding: Pour the calcined ceramic powder and reinforcing fiber into a pulverizer or grinder for grinding and grinding, and remove large solid particles in the material;

[0061] S3. Mixing and stirring: Pour the ground material, solution and water in the previous step into different mixing equipment for stirring according to requirements. At this time, when stirring and mixing, add calcined ceramic powder, nano-additives, and water into the same mixer and...

Embodiment 3

[0066] A method for processing a waterproof plugging material for civil building materials, comprising the following steps:

[0067] S1. Selection of materials: Select the following materials from the market: 50 parts of cationic neoprene emulsion, 2 parts of chemical root inhibitor, 25 parts of calcined ceramic powder, 2 parts of hydroxide solution, 4 parts of nano additives, 4 parts of thickener , 12 parts of reinforcing fiber, 6 parts of antifreeze, 15 parts of calcium powder, 20 parts of water;

[0068] S2. Crushing and grinding: Pour the calcined ceramic powder and reinforcing fiber into a pulverizer or grinder for grinding and grinding, and remove large solid particles in the material;

[0069] S3. Mixing and stirring: Pour the ground material, solution and water in the previous step into different mixing equipment for stirring according to requirements. At this time, when stirring and mixing, add calcined ceramic powder, nano-additives, and water into the same mixer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com