Two-stage porous polyimide material, preparation method thereof, two-stage porous polyimide retainer and application of two-stage porous polyimide retainer

A technology of porous polyimide and polyimide, which is applied in the field of polymer cages, can solve the problems of fast oil output, uneven pressure of materials, and uneven distribution of pore structure, so as to improve mechanical strength and facilitate molding , uniform pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a two-stage porous polyimide material, comprising the following steps:

[0032] Dissolving rigid aromatic diamines, flexible aromatic diamines and aromatic dibasic acid anhydrides in polar aprotic solvents, performing polycondensation reactions to obtain polyamic acid mixed solutions;

[0033] Mixing the polyamic acid mixed solution with a dehydrating agent to carry out imidization reaction to obtain polyimide molding powder;

[0034] The polyimide molding powder is subjected to cold isostatic pressing to obtain a cold-pressed blank;

[0035] The cold-pressed blank is subjected to hot isostatic pressing to obtain a polyimide material with two-stage pores.

[0036] In the present invention, unless otherwise specified, the preparation materials used are commercially available products well known to those skilled in the art.

[0037] In the invention, rigid aromatic diamine, flexible aromatic diamine and aromatic dibasic acid...

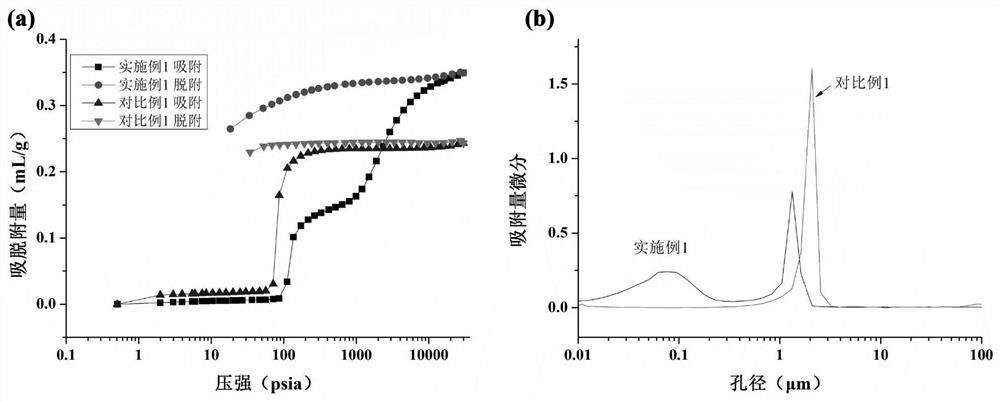

Embodiment 1

[0065] At normal temperature and pressure, in a nitrogen protective atmosphere, add 0.25mol 4,4'-diaminodiphenyl ether (ODA) and 2000g N-methyl Pyrrolidone (NMP), stirring rapidly for 0.5 hours, ODA was completely dissolved to obtain a homogeneous solution, slowly adding 0.25mol biphenyltetracarboxylic dianhydride (BPDA) powder in batches, and carrying out the first polycondensation reaction at a stirring speed of 100rpm for 12h to obtain Polyamic acid solution with rigid structure; add 0.75mol 1,4-bis(4-aminophenoxy)benzene (APB) and 1300g NMP, after stirring again to completely dissolve, add 0.75mol BPDA powder in batches, add 81g Solvent NMP, make the quality of NMP in the reaction system be 6 times of ODA, APB and BPDA three kinds of monomer total masses (being that mass concentration is 14.29wt%), under room temperature, carry out the second polycondensation reaction 12 hours under 100rpm stirring speed , to obtain a polyamic acid mixed solution;

[0066] Add 1183.4g tol...

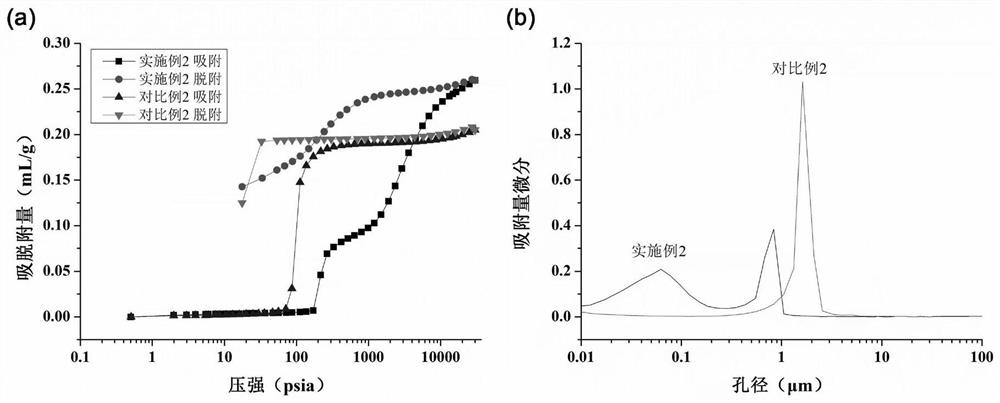

Embodiment 2

[0077] At normal temperature and pressure, in a nitrogen protective atmosphere, add 0.25mol ODA and 1200g N,N-dimethylformamide (DMF) to a three-necked flask equipped with mechanical stirring, a thermometer and a condenser, and stir rapidly for 0.5 Hours, ODA is completely dissolved to obtain a homogeneous solution, slowly add 0.25mol pyromellitic anhydride (PMDA) powder in batches, carry out the first polycondensation reaction 18h at a stirring speed of 200rpm, obtain a polyamic acid solution with a rigid structure; add 0.75molAPB, stir to make APB fully dissolve, then add 0.75mol PMDA powder in batches, add 262.2g solvent DMF, make the quality of DMF in the reaction system be 3 times of the three monomers of ODA, APB and PMDA (i.e. mass concentration 25.0wt%), at room temperature, the second polycondensation reaction was carried out at a stirring speed of 200rpm for 18 hours to obtain a polyamic acid mixed solution;

[0078] Add 390g of benzene to the polyamic acid mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com