Preparation method of hollow nano bowl-shaped structure, nano material and application

A nanomaterial and nano bowl technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation method of catalytic structure, slow preparation process and high preparation cost, and achieve enhanced catalysis, low preparation cost, The effect of enhancing catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

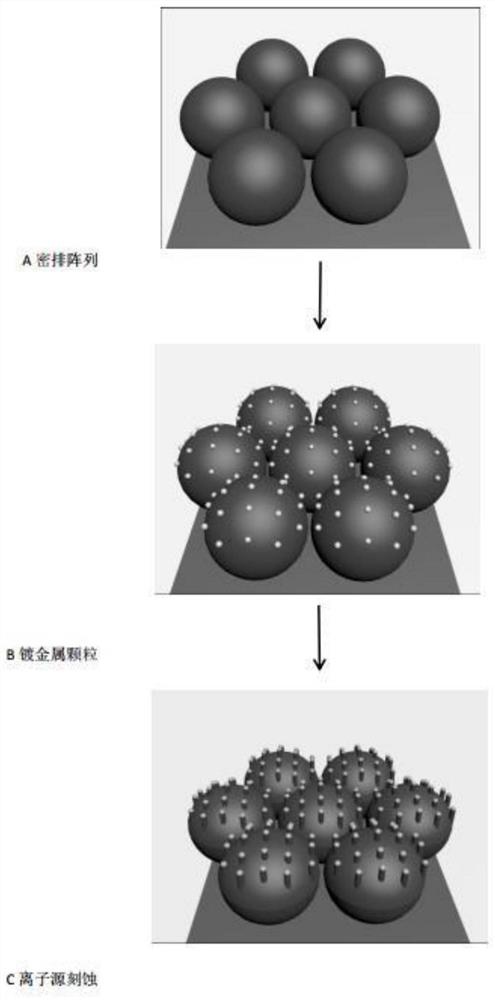

[0043] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a method for preparing a hollow nano-bowl structure, and the method for preparing comprises the following steps:

[0044] (A) Using the self-assembly method, a densely packed array of PS colloidal spheres with a diameter of 500 nm is self-assembled on a Si substrate with a hydrophilic surface to obtain an ordered nano-patterned structural template;

[0045] (B) Magnetron sputtering some copper particles on the surface of the ordered nano-patterned structure template obtained in step (A), and the sputtering time is 10s;

[0046] (C) plasma source etching of PS balls in the ordered nano-patterned structural template coated with copper particles obtained in step (B) for 20min;

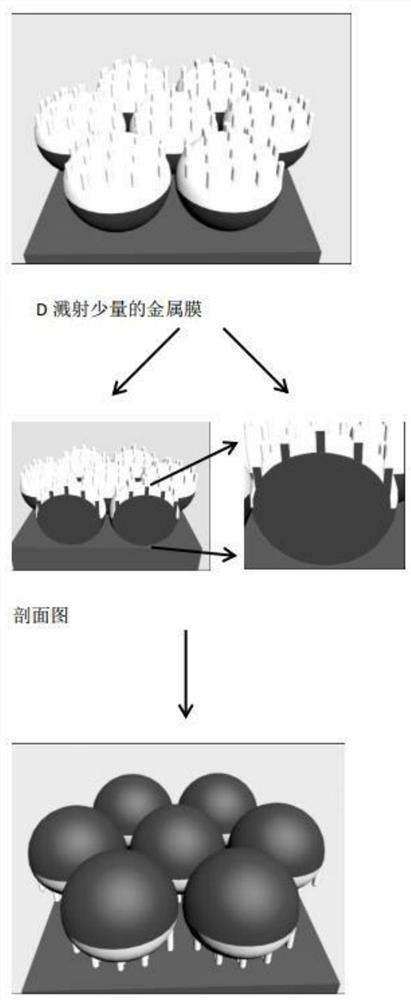

[0047] (D) to the structure magnetron sputtering after the etching that obtains in the step (C), the copper film of long 300nm;

[0048] (E) Paste and fix the structure obtained in step (D), and paste and fix th...

Embodiment 2

[0052] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a method for preparing a hollow nano-bowl structure, and the method for preparing comprises the following steps:

[0053] (A1) Using the self-assembly method, a densely packed array of PS colloidal spheres with a diameter of 200 nm is self-assembled on a Si substrate with a hydrophilic surface to obtain an ordered nano-patterned structural template;

[0054] (B1) Magnetron sputtering some copper particles on the surface of the ordered nano-patterned structure template obtained in step (A1), the sputtering time is 5s under the conditions of argon flux of 25mL / min and air pressure of 0.6Pa ;

[0055] (C1) Etching the PS ball plasma source in the ordered nano-patterned structural template coated with copper particles obtained in step (B1) for 10 min;

[0056] (D1) Magnetron sputtering of the etched structure obtained in the step (C1), a copper film with a length of 150 nm;

[0057] (E1...

Embodiment 3

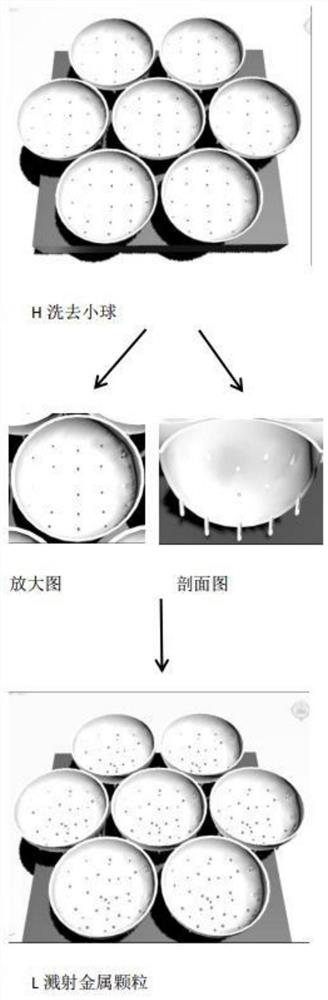

[0061] Such as figure 1 , Figure 4 and Figure 5 As shown, the present embodiment provides a method for preparing a hollow nano-bowl structure, and the method for preparing comprises the following steps:

[0062] (A2) Using the self-assembly method, a densely packed array of PS colloidal spheres with a diameter of 750 nm is self-assembled on a Si substrate with a hydrophilic surface to obtain an ordered nano-patterned structural template;

[0063] (B2) Magnetron sputtering some copper particles on the surface of the ordered nano-patterned structure template obtained in step (A2), the sputtering time is 15s under the condition of argon flux of 25mL / min and air pressure of 0.6Pa ;

[0064] (C2) After 30min plasma source etching of the PS pellets in the ordered nano-patterned structure template coated with copper particles obtained in step (B2), the following is obtained: figure 1 The structure shown in C;

[0065] (D2) to the structure magnetron sputtering after the etchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com