Doped lithium manganate and preparation method and application thereof

A lithium heteromanganate and manganese-based technology, applied in the field of material synthesis, can solve problems such as unresolved crystal plane growth, achieve the effects of improving cycle performance, reducing contact area, and reducing the probability of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] 1. Preparation method of doped lithium manganate

[0044]The first aspect of the present application provides a kind of preparation method of doped lithium manganese oxide, comprises the following steps:

[0045] S1, first prepare a manganese-based precursor with a controllable particle size distribution using a soluble manganese salt, and uniformly mix the dopant substance with the manganese-based precursor to obtain a mixture A; or directly mix the soluble manganese salt and the dopant substance, thereby Prepare a mixture A containing a manganese-based precursor and a dopant with a controllable particle size distribution;

[0046] S2, pretreating the mixture A;

[0047] S3, mixing the pretreated mixture A with a lithium salt to obtain a mixture B;

[0048] S4, raising the temperature of the mixture B in air or an oxidizing atmosphere to perform a solid phase sintering reaction to obtain doped lithium manganate with a controllable particle size.

[0049] The invento...

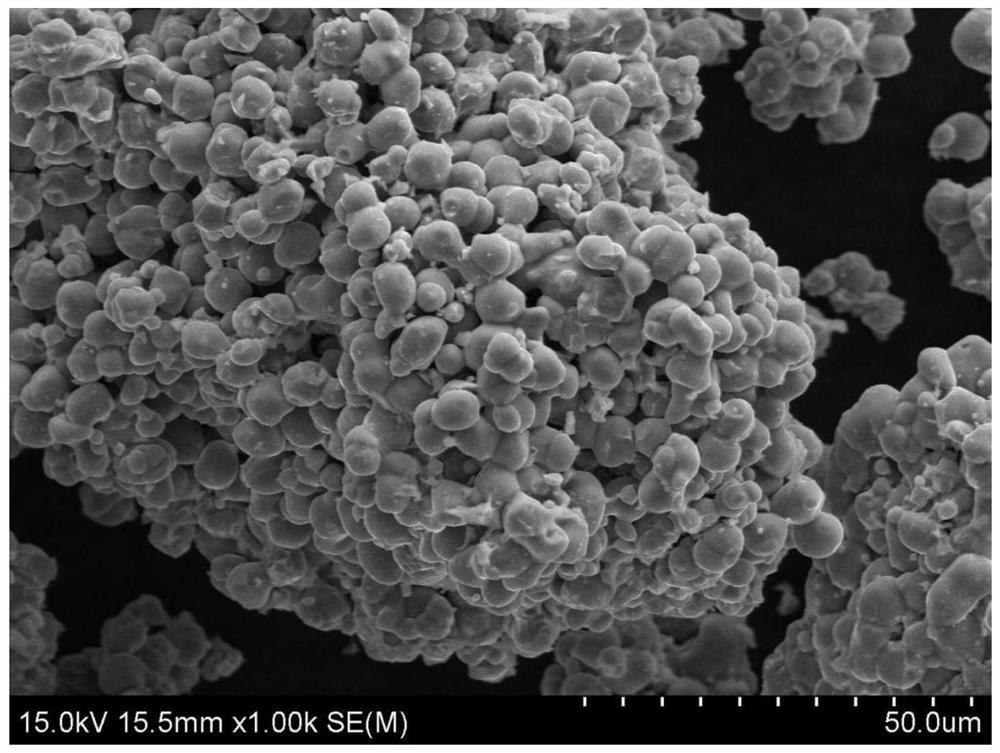

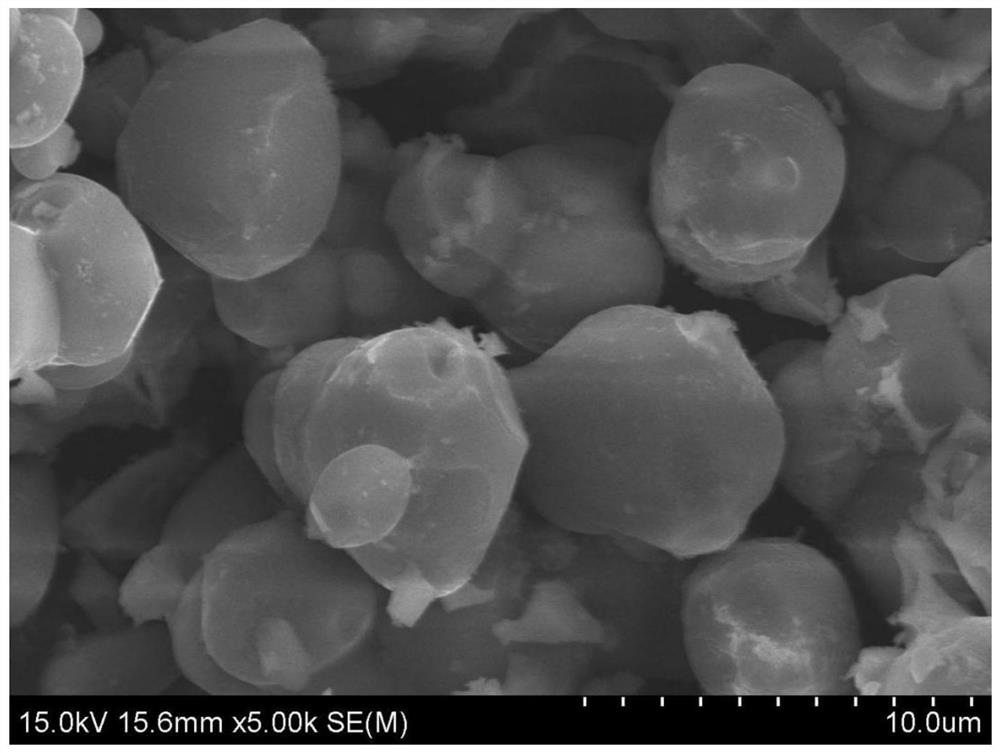

Embodiment 1

[0074] Preparation of doped lithium manganate:

[0075] S1, weigh 10g of manganese sulfate, add 30g of tap water to obtain a manganese sulfate solution; prepare a sodium hydroxide solution with a concentration of about 50g / L, drop the sodium hydroxide solution and the manganese sulfate solution into an empty beaker containing an appropriate amount of deionized water at the same time In the process, stir while adding dropwise, by controlling the dropping rate (0.1mL / min~0.5L / min), stirring rate (300rpm~2000rpm) and temperature (0℃~90℃) to control the particle size of the precipitate ( D50 is 2um-50um), and finally filtered, washed, and dried to obtain a manganese-based precursor. Weigh an appropriate amount of yttrium acetate and lanthanum acetate, wherein the molar ratio of lanthanum to yttrium is 1:1, and the ratio of the amount of manganese to yttrium and lanthanum is about 100:1, mix the mixture containing yttrium and lanthanum with the manganese precursor Mix well to obta...

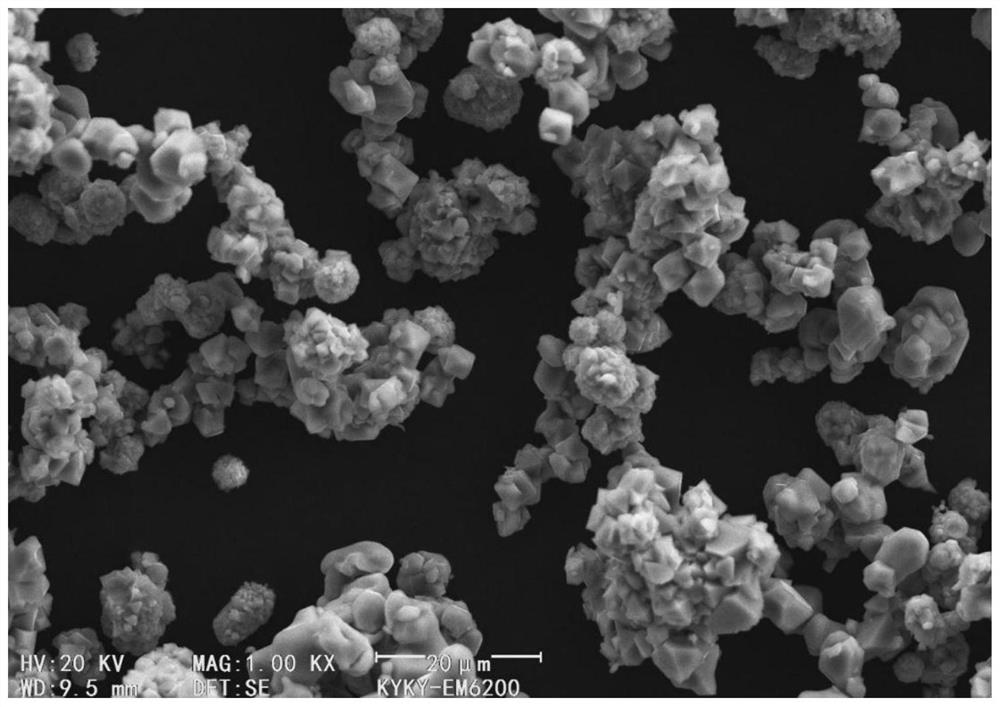

Embodiment 2

[0080] Preparation of doped lithium manganate:

[0081] S1, take by weighing 10g manganese acetate, add 30g tap water, obtain manganese acetate solution; Preparation concentration is about the sodium carbonate solution of 30g / L, sodium carbonate solution and manganese sulfate solution are added dropwise in the empty beaker that contains appropriate amount of deionized water simultaneously, Stir while adding dropwise, and control the particle size of the precipitate by controlling the dropping rate, stirring rate and temperature, and finally filter, wash, and dry to obtain the manganese-based precursor. Take an appropriate amount of yttrium acetate, lanthanum acetate and isopropyl titanate for later use, wherein the molar ratio of yttrium, lanthanum and titanium is 1:2:2, mix and stir it with the manganese precursor, and dry it to obtain a mixture A, wherein The ratio of the amount of manganese to the amount of substance of the elements M (yttrium, lanthanum and titanium) in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com