Medical magnesium-based alloy material and preparation method thereof

A magnesium-based alloy and alloy technology, applied in the fields of medical science, coating, prosthesis, etc., can solve the problems of unsatisfactory strength and biocompatibility of magnesium-based alloy materials, avoid surface cracking, high affinity Harmony, the effect of increasing the amount of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

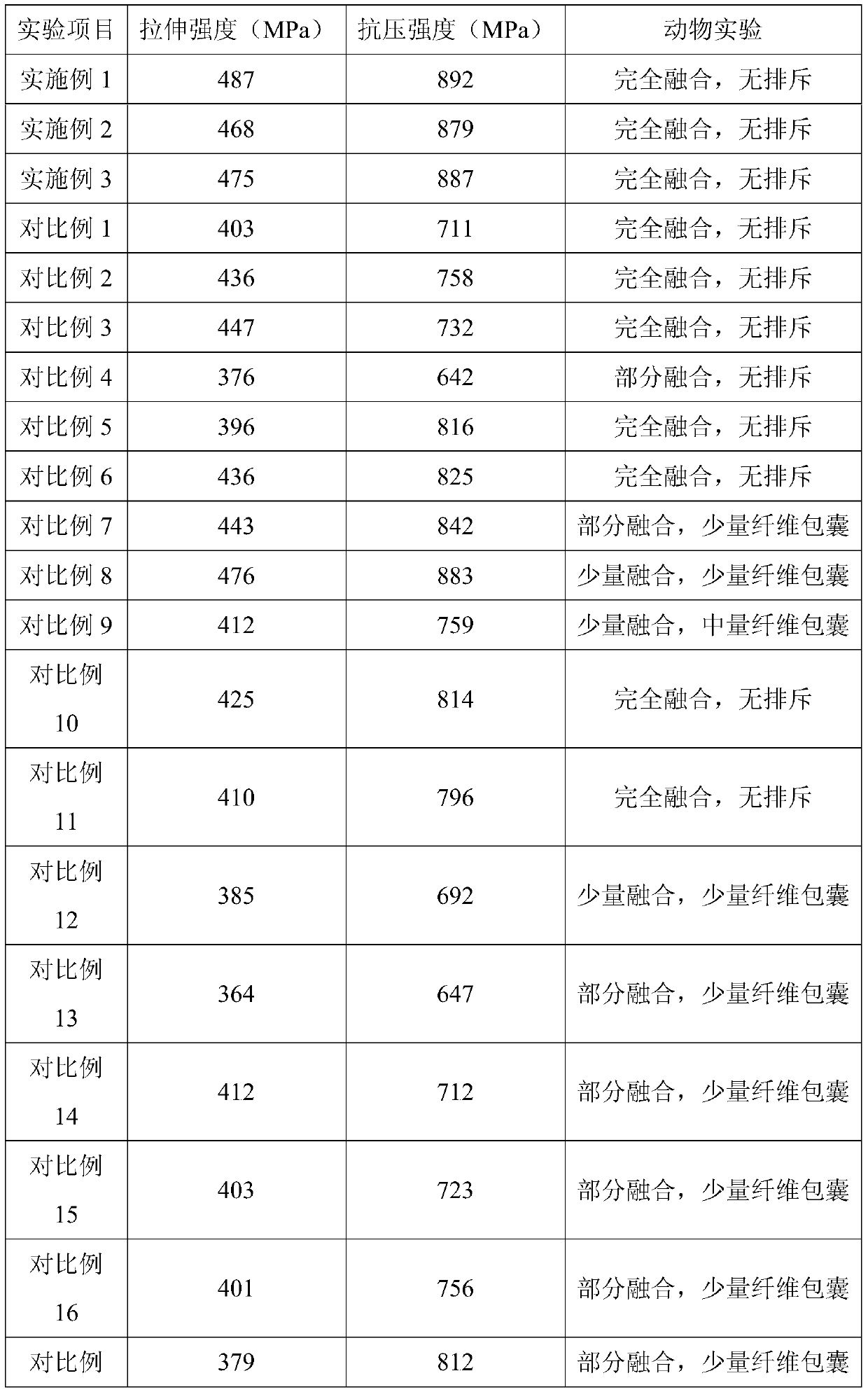

Examples

Embodiment 1

[0025] A medical magnesium-based alloy material, the medical magnesium-based alloy material includes an alloy matrix and a biological coating; the alloy matrix includes the following components by weight percentage: Cu 2.7%, Fe 0.9%, Sb 1.4%, Ta 0.6% , Ca 2.2%, V0.9%, Mo 0.3%, Ag1.3%, P 2.7%, Si 0.5%, F 0.03%, S 0.2%, nano-hydroxyapatite 5.8%, and the balance is Mg; The surface of the alloy matrix is polished to smooth the rough surface caused by nano-hydroxyapatite floating on the surface of the alloy matrix, and the thickness of the grinding is 1-3um; the main material of the biological coating is collagen fibers and several Buty. The ratio of collagen fibers and chitin in the biological coating is 2:1. The F is added by adding AgF.

[0026] The preparation method of the above-mentioned medical magnesium-based alloy material comprises the following steps: (1) weighing each component according to the above-mentioned mass percentage; (2) under a protective atmosphere, the pr...

Embodiment 2

[0028] A medical magnesium-based alloy material, the medical magnesium-based alloy material includes an alloy matrix and a biological coating; the alloy matrix includes the following components by weight percentage: Cu 2.2%, Fe 1.2%, Sb 1.2%, Ta 0.8% , Ca 1.2%, V1.2%, Mo 0.2%, Ag1.4%, P 2.2%, Si 0.7%, F 0.02%, S 0.3%, nano-hydroxyapatite 5.2%, and the balance is Mg; The surface of the alloy matrix is polished to smooth the rough surface caused by nano-hydroxyapatite floating on the surface of the alloy matrix, and the thickness of the grinding is 1-3um; the main material of the biological coating is collagen fibers and several Buty. The ratio of collagen fibers and chitin in the biological coating is 2:1. The F is added by adding AgF.

[0029] The preparation method of the above-mentioned medical magnesium-based alloy material comprises the following steps: (1) weighing each component according to the above-mentioned mass percentage; (2) under a protective atmosphere, the ...

Embodiment 3

[0031] A medical magnesium-based alloy material, the medical magnesium-based alloy material includes an alloy matrix and a biological coating; the alloy matrix includes the following components by weight percentage: Cu 3.2%, Fe 0.6%, Sb 1.6%, Ta 0.4% , Ca 3.2%, V0.6%, Mo 0.4%, Ag1.2%, P 3.2%, Si 0.3%, F0.04%, S 0.1%, nano-hydroxyapatite 6.4%, and the balance is Mg; The surface of the alloy matrix is polished to smooth the rough surface caused by nano-hydroxyapatite floating on the surface of the alloy matrix, and the thickness of the grinding is 1-3um; the main material of the biological coating is collagen fibers and Chitin. The ratio of collagen fibers and chitin in the biological coating is 2:1. The F is added by adding AgF.

[0032] The preparation method of the above-mentioned medical magnesium-based alloy material comprises the following steps: (1) weighing each component according to the above-mentioned mass percentage; (2) under a protective atmosphere, the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com