Production equipment and method of high-concentration coffee liquid

A technology for production equipment and coffee liquid, applied in coffee, coffee extraction, food science and other directions, can solve the problems of poor product quality, lack of effective ingredients, complicated process, etc., to reduce the loss of materials, reduce process costs, and simplify processes The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

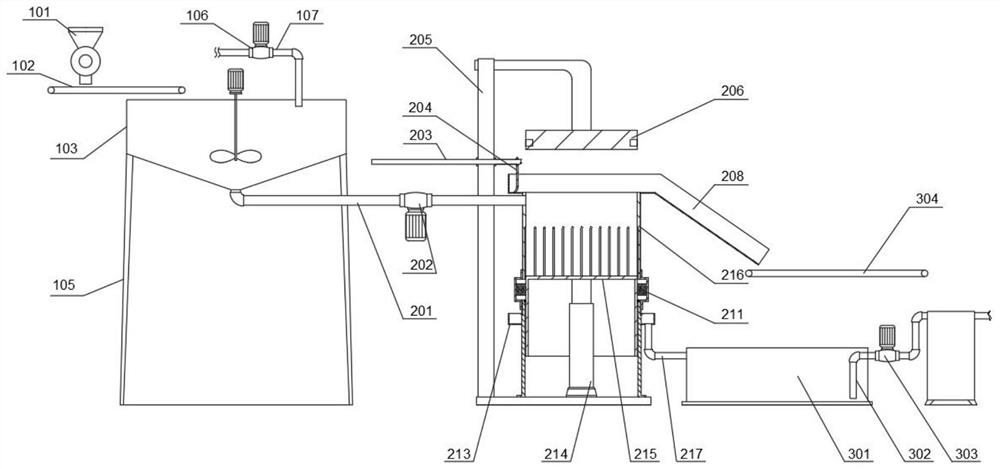

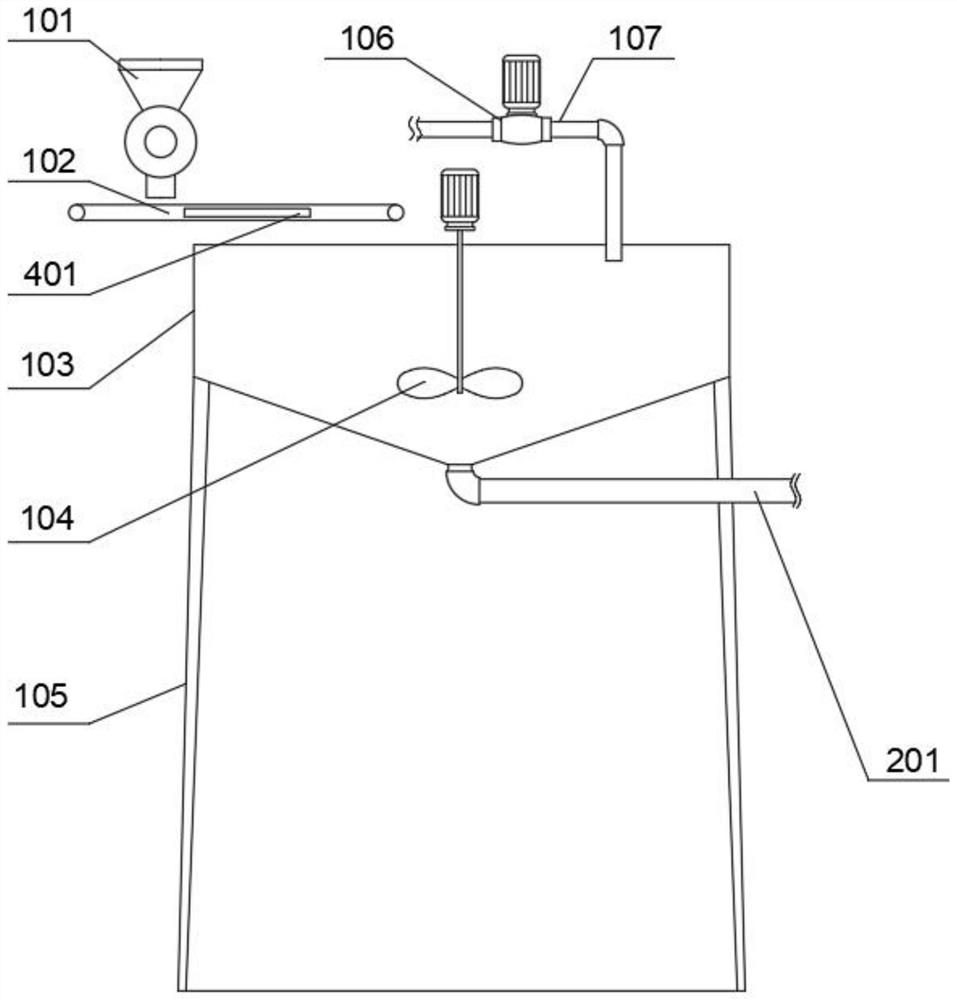

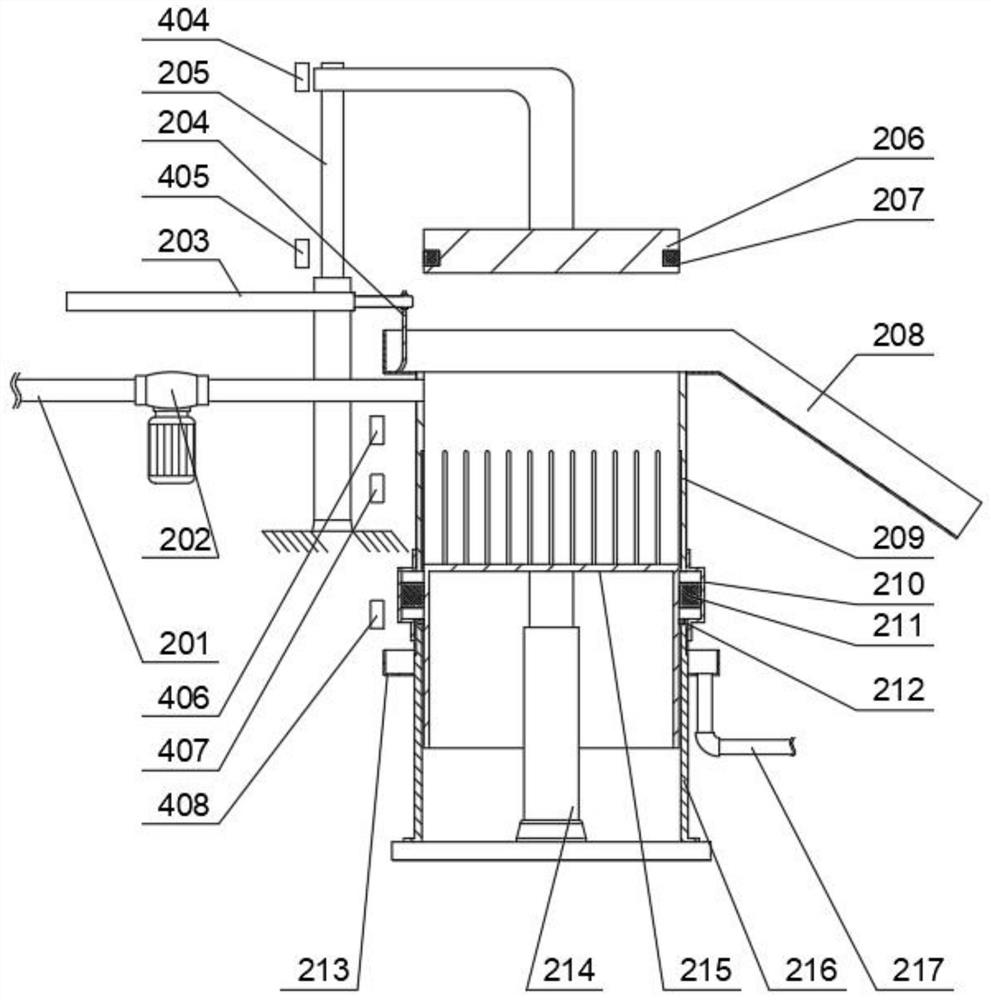

[0037] like Figure 1-8 As shown, the present invention relates to a production equipment of high-concentration coffee liquid, comprising a soaking tank support 105, a soaking tank 103 is installed on the upper end of the soaking tank support 105, a stirring device 104 is installed on the inside of the soaking tank 103, and the soaking tank 103 A weighing conveyor belt 102 is arranged above, a grinder 101 is arranged above the weighing conveyor belt 102, a pure water pipe 107 is installed on the upper end of the soaking tank 103, and a first metering pump 106 is installed before the outlet of the pure water pipe 107, so The outlet of the lower part of the soaking tank 103 is equipped with a conveying pipeline 201, a second metering pump 202 is installed on the outside of the conveying pipeline 201, an organic base 216 is installed on one end of the conveying pipeline 201, and an extrusion chamber 209 is installed on the upper end of the base 216. A slag discharge tray 208 is i...

Embodiment 2

[0046] On the basis of embodiment 1, a kind of production equipment of high-concentration coffee liquid produces the method for high-concentration coffee liquid, comprises the following steps:

[0047] Step 1: Grinding the roasted coffee beans according to a certain particle size to obtain ground coffee powder;

[0048] Step 2: Mix the ground coffee powder with cold water in a soaking tank according to a certain powder-to-water ratio and fully stir it evenly, place it in the soaking tank 103, mix it fully and soak for 50 minutes, and obtain coffee powder that is full of water and has no liquid overflow;

[0049] Step: 3: The mixture of water and coffee powder is placed in the soaking tank 103 and soaked for a certain period of time, so that the coffee powder is saturated with water and no excess water seeps out;

[0050] Step: 4: Extrude the water-saturated coffee powder for solid-liquid separation to obtain high-concentration coffee liquid and coffee grounds. The pressure dur...

Embodiment 3

[0054] On the basis of embodiment 2, a kind of production equipment of high-concentration coffee liquid produces the method for high-concentration coffee liquid, comprises the following steps:

[0055] Step 1: Put 100kg of Yunnan small-grain moderately roasted coffee beans into the grinder 101, and grind the coffee beans into powder at room temperature to obtain ground coffee powder with a particle size of 18 meshes, which is transported by the weighing conveyor belt 102 and weighed by the weighing sensor 401 In the soaking tank 103, pure water is transported through the pure water pipe 107 and measured by the first metering pump 106. According to the weight ratio of powder and water 1:1.8, add 180 kg of normal temperature pure water, and fully mix in the soaking tank 103 with the stirring device 104 Stir and soak for 50 minutes to obtain 280kg of coffee powder with a high water content that is full of water and does not overflow.

[0056] Step 2: The central processing unit P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com