Device and method for preparing poly-alpha-olefin

An olefin and pressure control technology, applied in chemical instruments and methods, hydrocarbon cracking, chemical/physical/physicochemical processes, etc., can solve the problem of large volume of stirred reactor, inability to achieve conversion rate and selectivity, and poor performance deal with problems such as catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

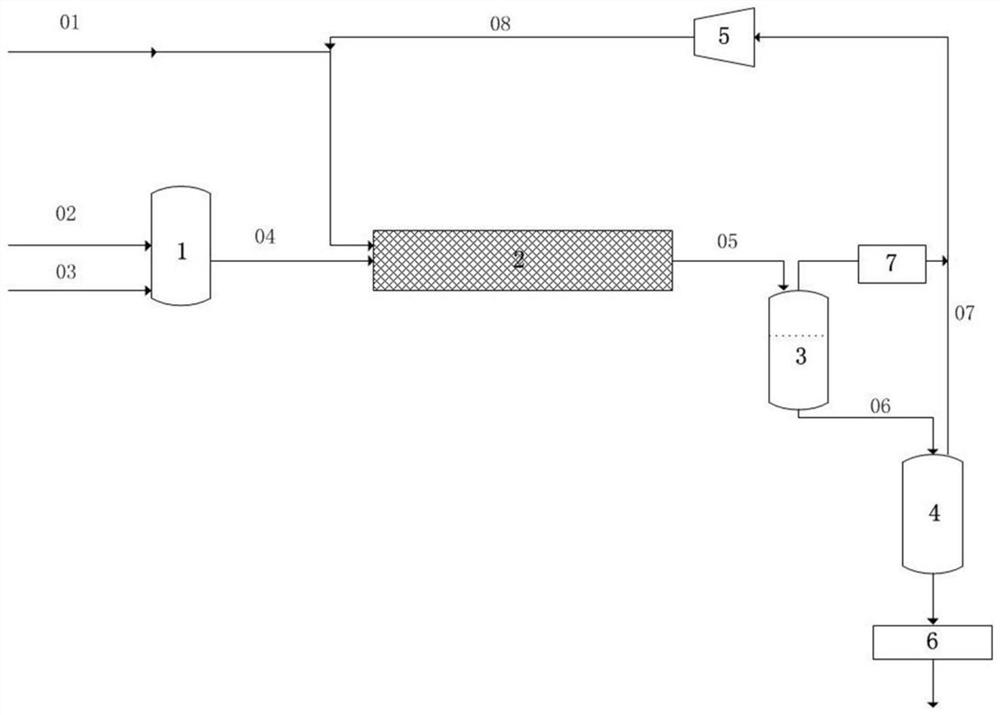

[0131] figure 1 It is a schematic diagram of the device for preparing polyalphaolefins of the present invention, which includes a mixing unit 1, a microchannel reaction unit 2, a high-pressure separation unit 3, a low-pressure separation unit 4, a gas circulation unit 5, a post-processing unit 6 and a pressure control unit 7 , the mixing unit 1 is connected to the microchannel reaction unit 2, the high pressure separation unit 3, the low pressure separation unit 4, and the gas circulation unit 5 successively, and the BF is set on the microchannel reaction unit 2 3 The gas inlet 01, the auxiliary agent inlet 02 and the olefin raw material inlet 03 are set on the mixing unit 1, and the gas circulation unit 5 and the BF 3 The gas inlet 01 is connected, the low-pressure separation unit 4 is connected to the post-processing unit 6 , the high-pressure separation unit 3 is connected to the pressure control unit 7 and the gas circulation unit 5 in sequence.

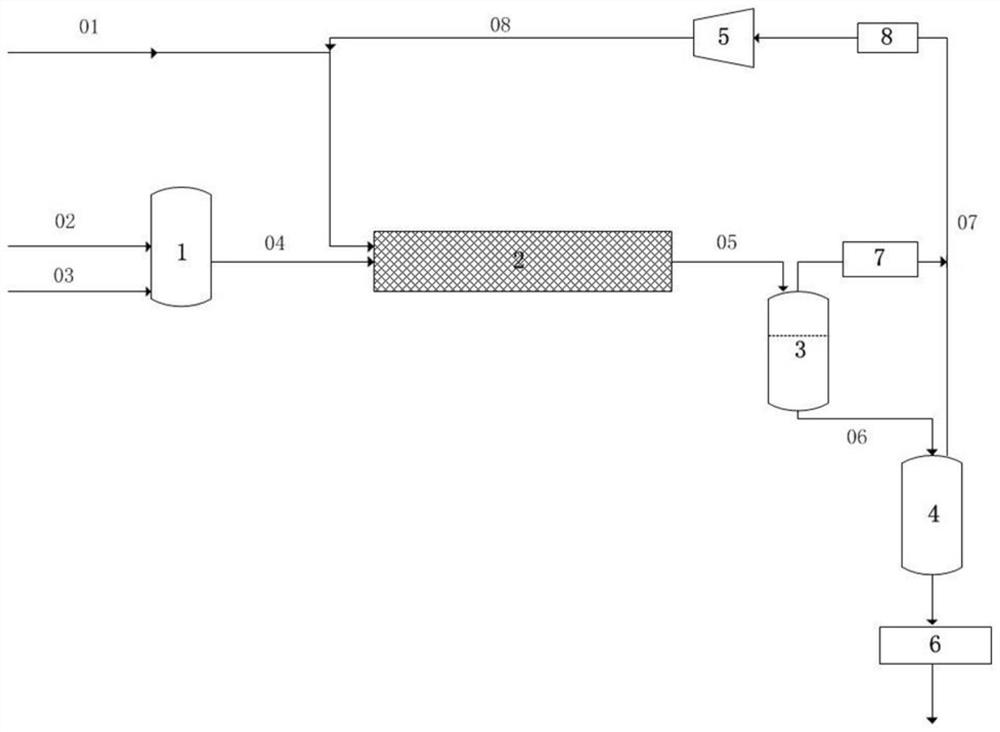

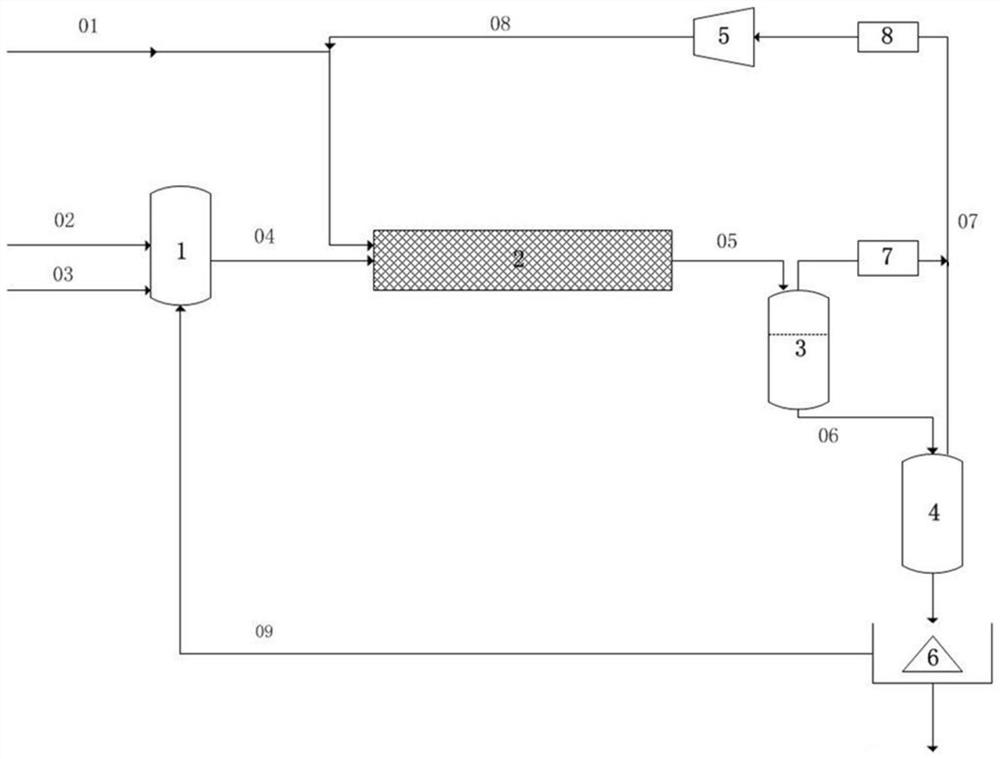

[0132] figure 2 is a s...

Embodiment 1

[0169] use attached figure 1 The apparatus shown carries out the polymerization of olefin feedstock. In the device, the mixing unit 1 is a mixer, the microchannel reaction unit 2 is a microchannel reactor, the high-pressure separation unit 3 is a high-pressure separator, the low-pressure separation unit 4 is a low-pressure separator, and the gas circulation unit 5 is a compressor. The post-processing unit 6 is a water washing device, and the pressure control unit 7 is a back pressure valve.

[0170] In the device, the structure and parameters of the mixer are: allowable process fluid temperature range: 20-200°C, working pressure upper limit (25°C): 10MPa; the structure and parameters of the microchannel reactor are: 8 channels, process fluid Temperature range: -20~200℃, maximum allowable reaction pressure: 6MPa, maximum allowable heat transfer medium pressure: 2MPa, including two temperature probes for measuring the temperature in the reaction system, fluid channel volume (wh...

Embodiment 2

[0181] Polymerization of the olefin feedstock was carried out using an apparatus for preparing polyalphaolefins as shown in Example 1. In the device, the structure and parameters of the mixer are: allowable process fluid temperature range: 20-200°C, working pressure upper limit (25°C): 10MPa; the structure and parameters of the microchannel reactor are: 8 channels, process fluid Temperature range: -20~200℃, maximum allowable reaction pressure: 6MPa, maximum allowable heat transfer medium pressure: 2MPa, including two temperature probes for measuring the temperature in the reaction system, fluid channel volume (when there is no mixing disk) : 50mL, the reaction volume is 30mL when packing the mixing piece, and the volume flow rate is 3–30L / h; the volume of the high-pressure separator is 1L, and the diameter is 10cm; the volume of the low-pressure separator is 15L, and the diameter is 50cm; the working parameters of the compressor are , Suction pressure: -0.1~0.03MPa, exhaust pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com