Method for preparing nepenthes bionic super-lubricating surface by using laser etching method

A laser etching and super-lubrication technology, which is applied to laser welding equipment, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of good hydrophobicity of super-lubricating surfaces, and achieve good hydrophobicity, thorough penetration, and no easy bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

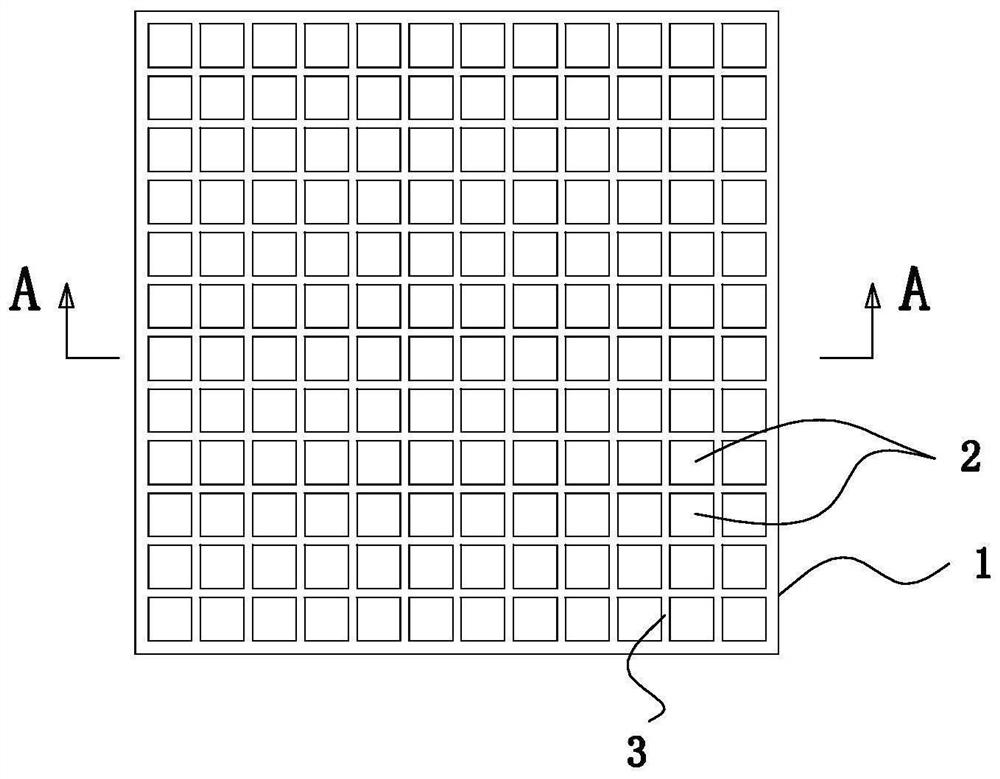

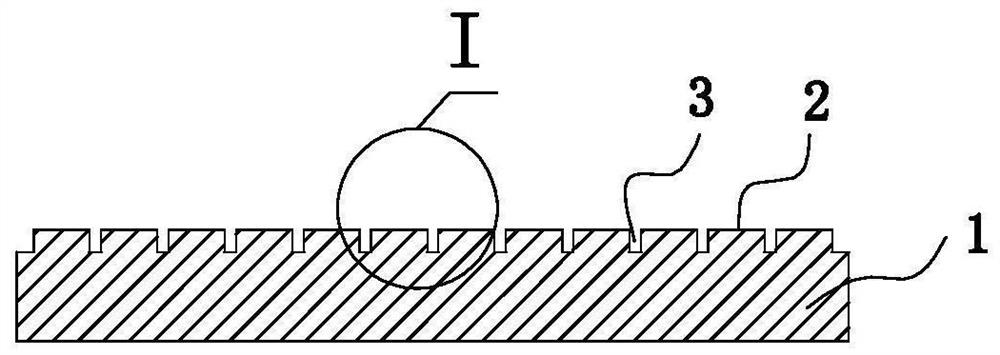

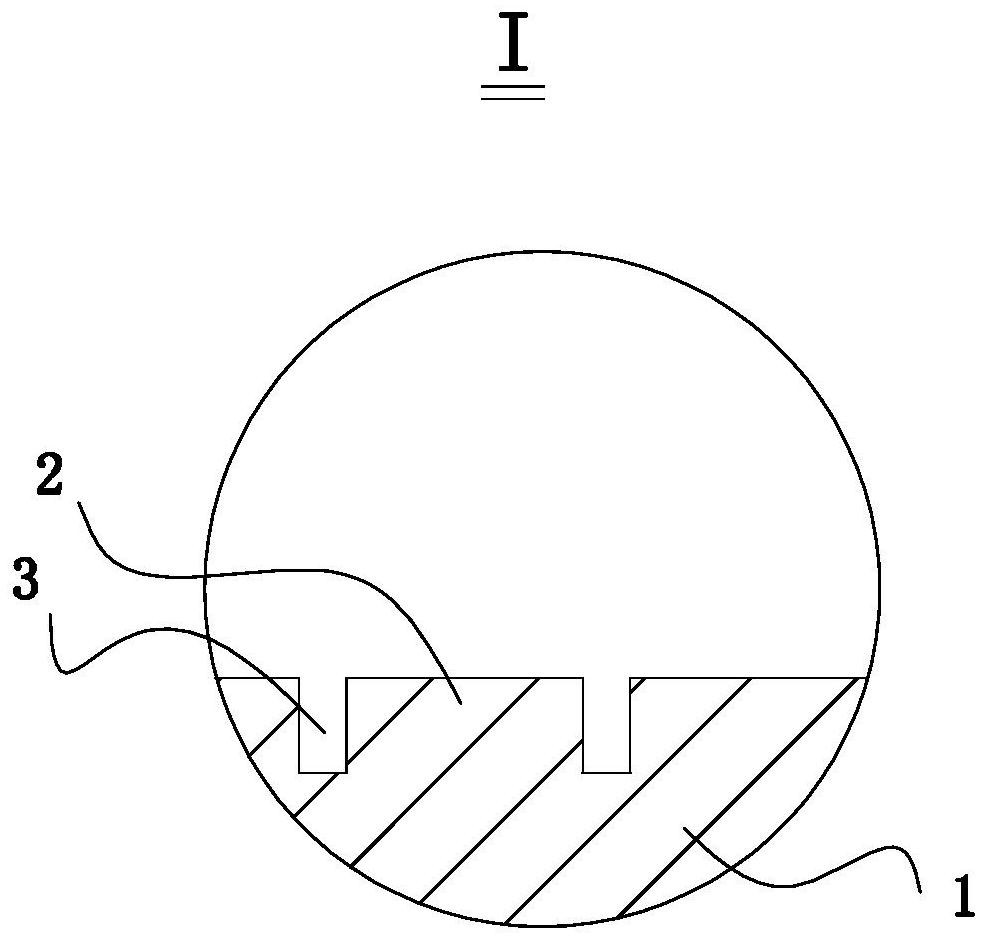

[0023] Such as Figure 1-4 As shown, the method for preparing an aluminum-based imitation pitcher plant super-lubricating surface by laser etching method comprises the steps as follows:

[0024] Step 1), the aluminum plate is cut into the size to be processed, and polished. In this embodiment, the aluminum plate is polished on sandpaper with a mesh number of 400#, 800#, 1000#, 1200#, 1500# and 2000#; The polishing machine is used for polishing to make a mirror surface; the polished aluminum plate is placed in deionized water and cleaned with an ultrasonic cleaner for 15 minutes; then placed in a drying oven and dried at 80°C for 30 minutes;

[0025] Step 2), placing the processed aluminum plate 1 under a nanosecond laser, and performing surface etching;

[0026] The nanosecond laser parameters are as follows: the wavelength is 1064nm, the average power is 10w, the scanning speed is 100mm / s, the repetition frequency is 20KHz, the pulse width is 50ns, the spot diameter is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com