Aluminum-based alloy low-temperature washing soldering paste and preparation method thereof

An aluminum-based alloy, low-temperature technology, applied in welding equipment, metal processing equipment, welding media, etc., can solve the problems that cannot meet the requirements of brazing and sealing of refrigeration system components, achieve good metallurgical bonding structure, avoid sedimentation and stratification, The effect of easy filling of weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

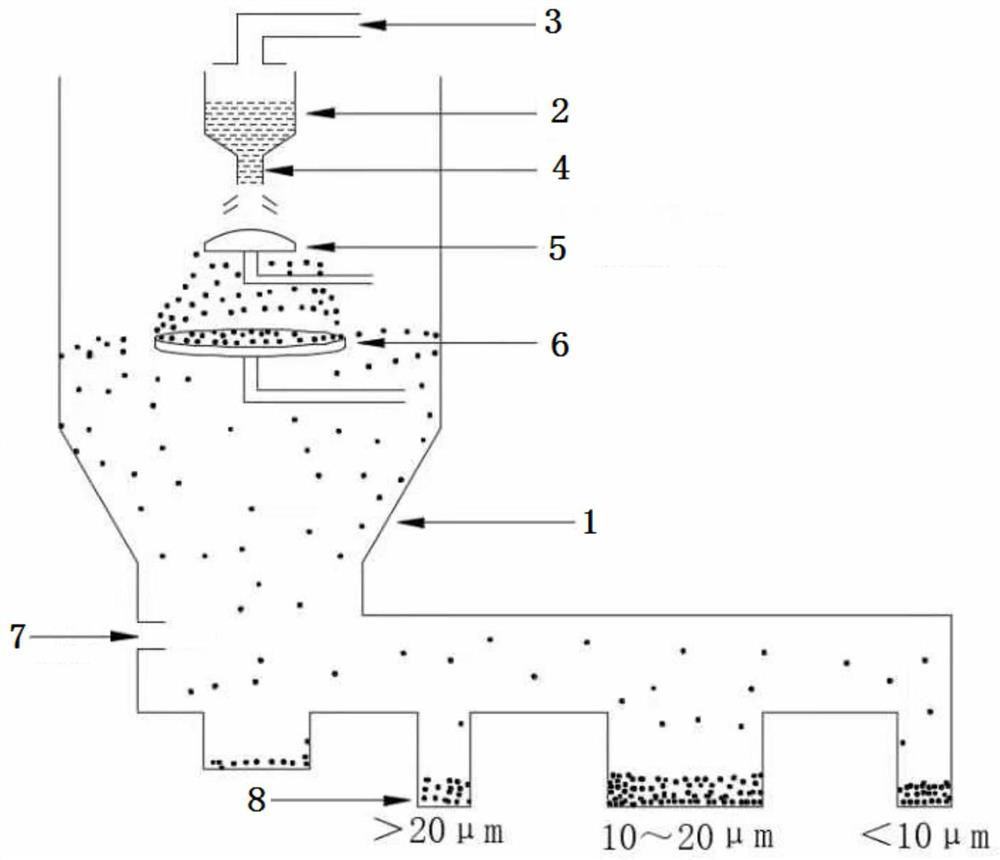

[0051] Example 1 Ultrasonic centrifugal atomization equipment

[0052] The ultrasonic centrifugal atomization equipment used in the present invention is as figure 1 As shown, the ultrasonic centrifugal atomization equipment includes a preparation bin 1 , a tundish 2 , a draft tube 4 , an umbrella-like ultrasonicator 5 , a centrifugal disc 6 , an air-filled tube 7 and a collection bin 8 .

[0053] A tundish 2 , a draft tube 4 , an umbrella-shaped ultrasonic device 5 and a centrifugal disc 6 are sequentially arranged in the preparation chamber 1 from top to bottom.

[0054] There is a heating device on the tundish 2 . The top of the tundish is connected to the nitrogen pipe 3 and has an alloy solution casting port. The bottom of the tundish 2 is connected with a diversion tube 4, and the diameter of the diversion tube is 2-5 mm.

[0055] Below the guide tube 4 is an umbrella-shaped ultrasonic device 5 , the upper surface of the ultrasonic device is in the shape of an umbrella...

Embodiment 2

[0058] Example 2 Preparation of Aluminum-Based Alloy Low-Temperature Washing Solder Paste (1)

[0059] (1) material preparation

[0060] Weigh 692.8 grams of Al, 170 grams of Ag, 76 grams of Cu, 60 grams of Si, 1 gram of Ni and 0.2 grams of Ce.

[0061] (2) Preparation of master alloy

[0062] Using a non-vacuum intermediate frequency induction furnace, add Al ingots into the graphite crucible, heat up and after the aluminum ingots are melted, add 10g of covering agent and slag remover (the composition is AlF 3 : 45wt%, KF: balance), fully stirred, the temperature of the furnace was raised to 800°C, and Ag, Cu, Si, Ce were added in batches. After all the metals were melted, they were refined for 20 minutes, cast into ingots, and respectively obtained Al-30Ag, Al-50Cu, Al-30Si, Al-10Ce master alloys.

[0063] Using a vacuum intermediate frequency induction furnace, add pure Cu and pure nickel into the graphite crucible, and the furnace is vacuumed to 10 -1 Pa, the furnace t...

Embodiment 3

[0070] Example 3 Preparation of Aluminum-Based Alloy Low-Temperature Washing Solder Paste (2)

[0071] (1) material preparation

[0072] Weigh 639 grams of Al, 190 grams of Ag, 60 grams of Cu, 100 grams of Si, 10 grams of Ni and 1 gram of Ce.

[0073] (2) Preparation of master alloy

[0074] Al-30Ag, Al-50Cu, Al-30Si, Al-10Ce, Cu-30Ni master alloys were respectively prepared by the same method as in Example 2.

[0075] (3) Preparation of aluminum-based alloy powder by ultrasonic centrifugal atomization

[0076] The ultrasonic centrifugal atomization equipment described in Example 1 is used for powder preparation, and the remaining high alumina and Al-30Ag, Al-50Cu, Al-30Si, Al-10Ce, Cu-30Ni master alloys are respectively mixed according to the design component ratio , calculated and weighed respectively, and put into an alumina crucible; melt the solder alloy in an intermediate frequency induction furnace, the heating power is 30KW, and the melting temperature is 800°C; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com