Thick coating type whitening-resistant waterproof coating and preparation method thereof

A waterproof coating and anti-whitening technology, which is applied in the coating and other directions, can solve the problems of reducing customer satisfaction with the product, affecting the appearance of the waterproof coating film, and uneven color on the surface of the coating film, achieving a good anti-whitening effect and preventing flooding whitening phenomenon, reduce capillary channel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The application provides a thick-coated anti-whitening waterproof coating and a preparation method thereof. The coating is two-component, which includes A component and B component, and A component includes the following substances in parts by mass: 30-60 parts of cement, 20-50 parts of filler, 10-40 parts of quartz sand, 0 parts of sugar ~10 parts, 0~3 parts of water reducing agent, 2~8 parts of calcium formate; B component includes the following substances by mass: 70~95 parts of polymer styrene-acrylic emulsion, 2~8 parts of polymer VAE emulsion, thickening 0-1 part of antifoaming agent, 1-7 parts of antifoaming agent, 0-4 parts of fungicide, 50-200 parts of water.

[0028] The waterproof coating of the present invention comprises A component and B component. The polymer VAE emulsion in component A can effectively improve the compactness of the coating film, reduce the capillary channels of the coating film, and reduce the migration of calcium ions; while the calciu...

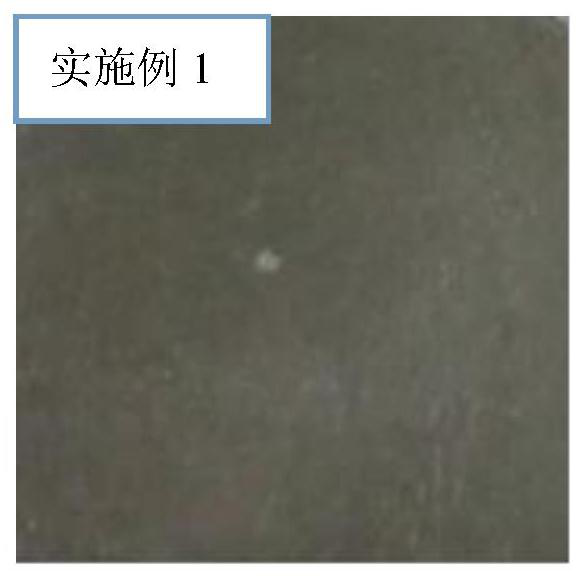

Embodiment 1

[0043] A thick-coated anti-whitening waterproof coating, the coating includes A component and B component, A component includes the following materials in parts by mass: 450 parts of cement, 332 parts of 325 heavy calcium, 212 parts of quartz sand, 4 parts of sucrose parts, 1 part of water reducer, 5 parts of calcium formate; B component includes the following parts by mass: 880 parts of polymer styrene-acrylic emulsion, 40 parts of polymer VAE emulsion, 0.1 part of thickener, 5 parts of defoamer, 2 parts of fungicide, 73 parts of water. The mass ratio of component A and component B is 1:1.5.

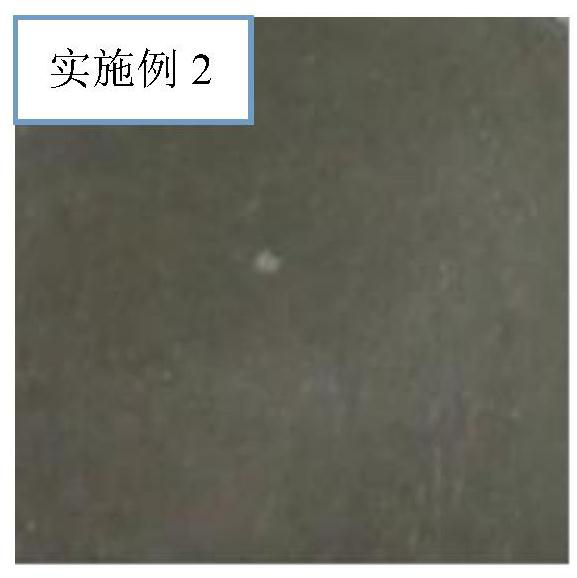

Embodiment 2

[0045] A thick-coated anti-whitening waterproof coating, the coating includes A component and B component, A component includes the following materials in parts by mass: 450 parts of cement, 332 parts of 325 heavy calcium, 212 parts of quartz sand, gluconic acid 4 parts of sodium, 1 part of water reducer, 5 parts of calcium formate; component B includes the following parts by mass: 880 parts of polymer styrene-acrylic emulsion, 40 parts of polymer VAE emulsion, 0.1 part of thickener, 5 parts of defoamer 2 parts, 2 parts of fungicide, 73 parts of water. The mass ratio of component A and component B is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com