Cathode material for electrolysis of water, preparation method of cathode material, and application of cathode material in electro-catalytic hydrogenation reduction of dyes

A cathode material, a technology for electrolyzing water, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low overpotential, single, low current use efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

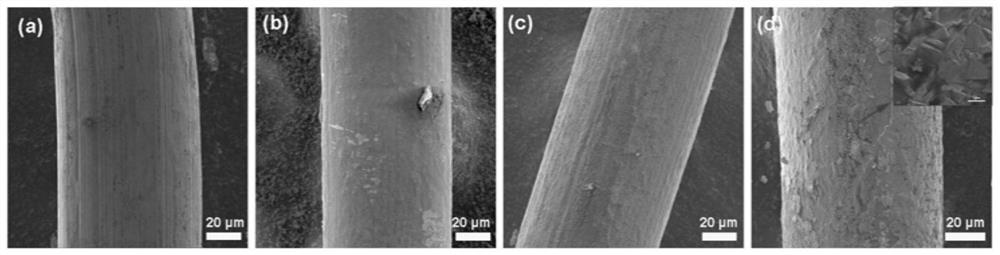

[0200] (1) pretreatment is carried out to the base material: 320 meshes and 600 meshes of SiC sandpaper are used to polish stainless steel successively, remove the surface layer, and then use a potentiostat to remove the surface oxide layer in the sulfuric acid solution of 1mol / L;

[0201] (2) Pre-nickel plating: Cut the pretreated stainless steel into 1 × 2 cm blocks, and then plated them in 1 mol / L NiCl 2 ·6H 2 -160 mA cm in O solution 2 Electrodeposition was performed for 20 minutes to obtain stainless steel with nickel coating;

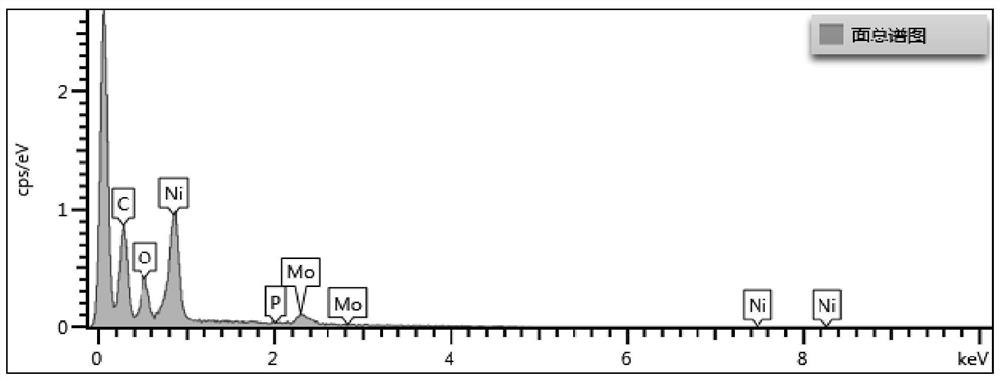

[0202] (3) Preparation of Ni-Mo-P / stainless steel cathode material: prepare a catalyst plating solution containing Ni, Mo, and P, the composition of the catalyst plating solution is shown in Table 1, and then adjust the pH of the catalyst plating solution to 9, and then Using the three-electrode method, the stainless steel with nickel coating was placed in the catalyst bath at -100 mA cm 2 Under electroplating for 5 minutes, a Ni-Mo-P / stainless...

Embodiment 2

[0204] (1) Pretreatment of the base material: soak the nickel foil in a 1mol / L hydrochloric acid solution for 20 minutes;

[0205] (2) Pre-nickel plating: Cut the pretreated nickel foil into a 1×2cm block, and then plated it in 1.5mol / L NiCl 2 ·6H 2 -160 mA cm in O solution 2 Electrodeposition was performed for 15 minutes to obtain a nickel foil with a nickel coating;

[0206] (3) Preparation of Ni-Mo-P / nickel foil cathode material: prepare a catalyst plating solution containing Ni, Mo, and P, the composition of the catalyst plating solution is shown in Table 1, and then adjust the pH of the catalyst plating solution to 10, Then the three-electrode method was used to place the nickel foil with nickel coating in the catalyst bath at -100 mA cm 2 Under electroplating for 5 minutes, a Ni-Mo-P / nickel foil cathode material was obtained.

Embodiment 3

[0208] (1) Pretreatment of the base material: soak the copper foil in a 1.5mol / L hydrochloric acid solution for 15 minutes;

[0209] (2) Pre-nickel plating: Cut the pretreated copper foil into a 1×2cm block, and then immerse it in 0.5mol / L NiSO 4 ·6H 2 -160 mA cm in O solution 2 Electrodeposition was performed for 25 minutes to obtain copper foil with nickel plating;

[0210] (3) Preparation of Ni-Mo-P / copper foil cathode material: prepare a catalyst plating solution containing Ni, Mo, and P, the composition of the catalyst plating solution is shown in Table 1, and then adjust the pH of the catalyst plating solution to 9.5, Then, the copper foil with nickel coating was placed in the catalyst bath at -100 mA cm by the three-electrode method. 2 Under electroplating for 15 minutes, a Ni-Mo-P / copper foil cathode material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com