Graphene composite amorphous metal-based sulfide electrode material and preparation method thereof

A graphene composite and amorphous metal technology, applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve problems such as insignificant advantages, difficult controllability, failure of battery storage units, etc., to achieve excellent performance and avoid Improvement of electrode degradation and volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

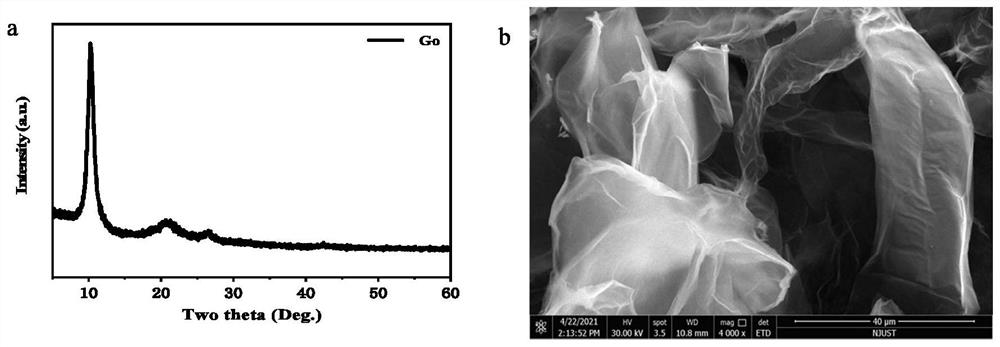

[0036] (1) Graphite powder was treated with 5% dilute hydrochloric acid to improve the hydrophilicity of graphite, and then dried in a vacuum oven at 80 ºC to obtain flake graphite.

[0037] (2) Weigh 5 g flake graphite and 5 g potassium permanganate in advance, measure 500 mL of concentrated sulfuric acid and 500 mL of deionized water, and prepare a sufficient amount of hydrogen peroxide; set the ice bath temperature of the ice bath at 0°C Perform pre-cooling; weigh 5 g flake graphite and pour it into a 3 L beaker, set the magneton speed properly (fully mix the reactants to avoid splashing of the mixed solution); slowly pour 500 mL of concentrated sulfuric acid into the beaker, pay attention to control and keep ice Bath temperature is 0~3ºC; fully mechanically mix; slowly add 5 g potassium permanganate to the beaker, pay attention to control and keep the ice bath temperature at 0~3ºC; set the water bath temperature of the water bath machine to 35ºC, wait until the mixture is f...

Embodiment 2

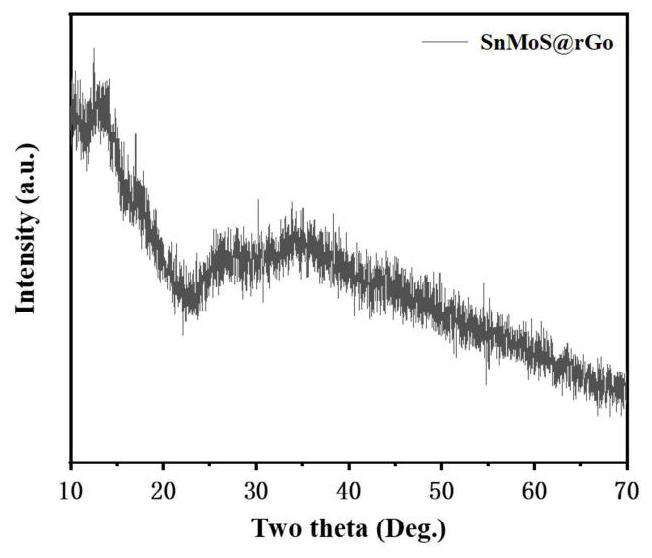

[0041] (1) First set the temperature of the oil bath at 70 °C for preheating; use a graduated cylinder to measure 15 mL of the GO ethanol dispersion in Example 1 at 1 mg / mL, add it to an 80 mL reaction bottle, and then add About 20 mL of absolute ethanol; weigh 2.4720 g of ammonium molybdate tetrahydrate, 0.1128 g of stannous chloride dihydrate and 0.3750 g of thioacetamide, and add them to the reaction flask; add to the reaction flask Add anhydrous ethanol to the 80 mL mark; seal the reaction bottle with plastic wrap, screw the cap tightly, and place it in a preheated 70°C oil bath; turn on the magnetic stirring and set the speed to 450 r / min; react for 12 hours; Take out the reaction bottle from the oil bath, add absolute ethanol to accelerate the cooling, seal it with plastic wrap and let it stand for 30-60 min; take the upper precipitate and centrifuge 3 times with absolute ethanol, and then centrifuge 3 times with deionized water; disperse the product in Put it in deioniz...

Embodiment 3

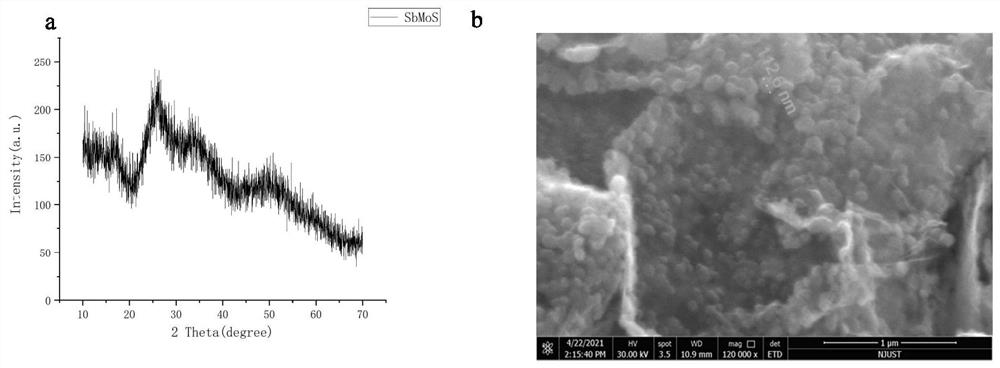

[0045] (1) First set the temperature of the oil bath at 70 °C for preheating; use a graduated cylinder to measure 15 mL of the GO ethanol dispersion in Example 1 at 1 mg / mL, add it to an 80 mL reaction bottle, and then add About 20 mL of absolute ethanol; weigh 2.4720 g of ammonium molybdate tetrahydrate, 0.3750 g of thioacetamide and 0.1142 g of antimony chloride into the reaction flask; add absolute ethanol to the reaction flask to 80 mL scale line; seal the reaction bottle with plastic wrap and tighten the cap, put it into a preheated 70°C oil bath; turn on the magnetic stirring and set the speed to 450 r / min; react for 12 hours; take it out of the oil bath Add absolute ethanol to the reaction bottle to accelerate cooling, seal it with plastic wrap and let it stand for 30-60 min; take the upper precipitate and centrifuge three times with absolute ethanol, and then centrifuge three times with deionized water; disperse the product in deionized water, place Spread out on a pet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com