Preparation method for heat insulation aluminum alloy profile

An aluminum alloy profile and aluminum alloy-based technology, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, which can solve the problem of poor overall strength of the profile, large heat transfer coefficient, and profile hardness cracks, etc. problems, to ensure decorative and weather resistance, improve compatibility, and enhance longitudinal shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

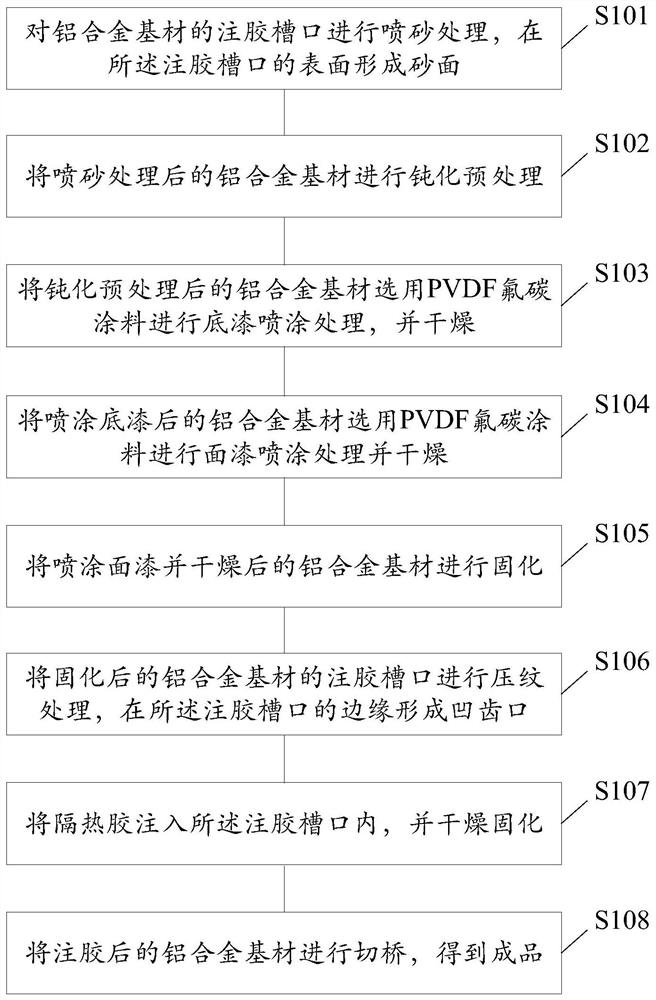

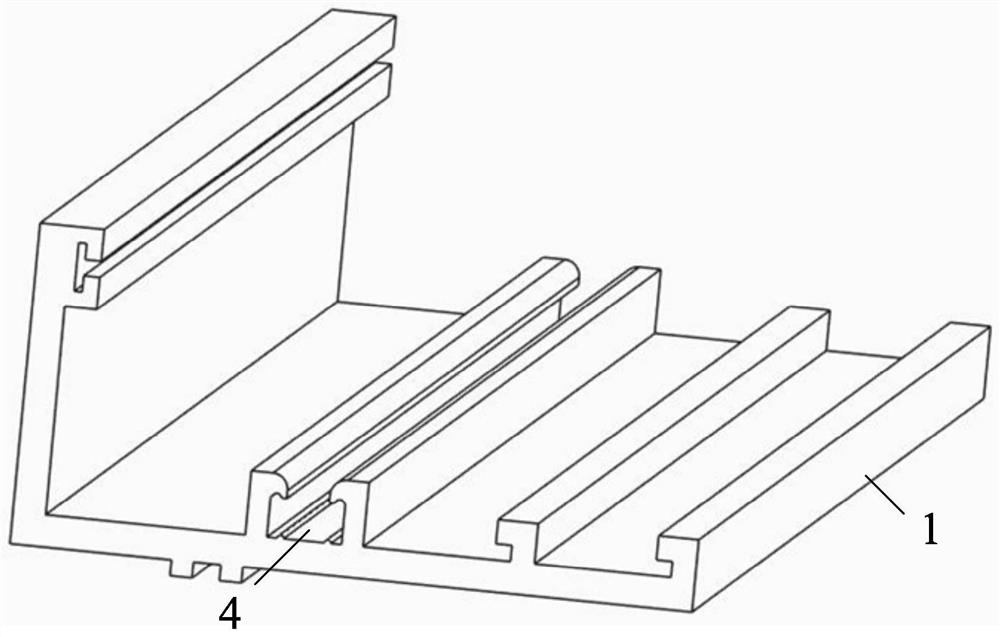

[0046] Such as figure 1 As shown, the invention provides a method for preparing a heat-insulating aluminum alloy profile, comprising the following steps:

[0047] S101. Sandblasting the glue injection notch of the aluminum alloy base material, forming a sand surface on the surface of the glue injection notch;

[0048] Step S101 includes:

[0049] Place the injection notch of the aluminum alloy base material facing upwards;

[0050] Shot peening with a particle size of 0.1-0.5 mm is used for coarse sand treatment to form a sand surface on the surface of the glue injection notch. Preferably, the shot peening is 0.2-0.3mm.

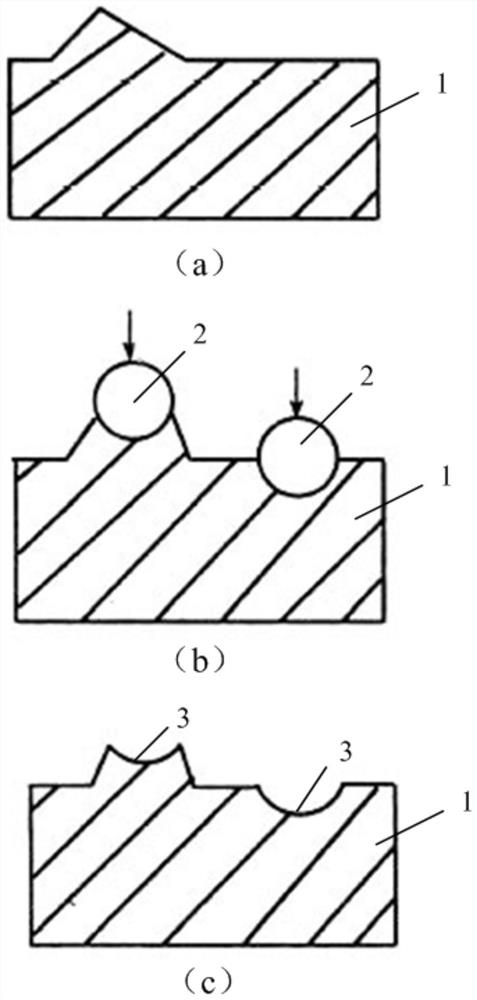

[0051] The present invention uses mechanical pretreatment to increase the roughness of the surface of the glue injection notch of the profile, and produces a uniform and fine concave-convex surface on the surface of the glue injection notch, ensuring that there are enough anchor points after the subsequent heat insulation material is poured, and its longit...

Embodiment 1

[0089] (1) Place the glue injection notch of the aluminum alloy base material upwards, use shot blasting with a particle size of 0.1 mm to carry out coarse sand treatment, and form a sand surface on the surface of the glue injection notch;

[0090] (2) The aluminum alloy substrate is washed with water, degreasing pretreatment, water washing, forming a passivation film, washing with water, and drying in sequence, wherein the amount of degreasing etching is 1.5g / m 2 The passivating agent is a chromium phosphate passivating agent;

[0091] (3) Dilute the primer with a diluent until the viscosity is 10', and then use the spraying equipment to spray the primer on the surface of the profile to form a layer of coating film. The thickness of the coating film is controlled at 7 μm. Among them, the primer is PVDF fluorine Carbon coating, the raw material of PVDF fluorocarbon coating includes resin, wherein, the resin includes fluorocarbon resin, and the ratio of the fluorocarbon resin t...

Embodiment 2

[0098] (1) Place the glue injection notch of the aluminum alloy base material upwards, use shot blasting with a particle size of 0.2 mm to carry out coarse sand treatment, and form a sand surface on the surface of the glue injection notch;

[0099] (2) The aluminum alloy substrate is washed with water, degreasing pretreatment, water washing, forming a passivation film, washing with water, and drying in sequence, wherein the amount of degreasing and etching is 1.8g / m 2 The passivating agent is a chromium phosphate passivating agent;

[0100](3) Dilute the primer with a diluent to a viscosity of 12', and then use the spraying equipment to spray the primer on the surface of the profile to form a layer of coating film. The thickness of the coating film is controlled at 10 μm. Among them, the primer is PVDF fluorine Carbon coating, the raw material of PVDF fluorocarbon coating includes resin, wherein, the resin includes fluorocarbon resin, and the ratio of the fluorocarbon resin to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com