Method for smelting molten nickel iron with low cost and high productivity

A low-cost technology of molten nickel iron, applied in the field of iron and steel metallurgy, can solve the problems of high smelting power consumption, fluctuating furnace conditions, limited load lifting, etc., and achieves the effect of improving roasting efficiency, ensuring furnace lining refractories, and reducing electrode oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

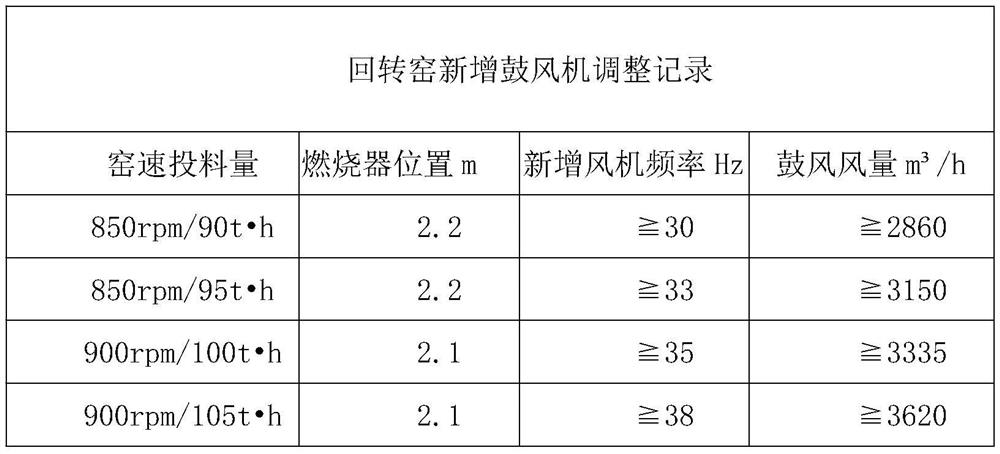

[0043] A method for smelting molten nickel iron with low cost and high production capacity, comprising the following steps:

[0044]S1 crushing and mixing: dry the laterite nickel ore with high water content in the open air yard, and reduce the moisture of the raw ore as much as possible before entering the process; then transfer it to the raw material greenhouse according to the production rhythm, and then crush and screen large pieces of laterite nickel ore And mix and stir to make it evenly mixed;

[0045] S2 Drying: Use a drying kiln to dry the raw ore in step S1, so that the moisture content of the raw ore is controlled at 23-26%; this will not only reduce the sticky ore, but also reduce the smoke and dust production in the whole process, reduce the loss of Ni content, and reduce the rotation The calcining pressure and coal consumption of the kiln. (The moisture content of dry ore can be adjusted according to the moisture content of raw ore, weather conditions, on-site d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com