Fuel cell metal connector coating

A metal connector, fuel cell technology, applied in fuel cells, fuel cell parts, metal material coating processes, etc., can solve the problem of the decline of ion transmission efficiency of proton exchange membrane, the decline of fuel cell performance, and the increase of interface contact resistance. and other problems, to achieve the effect of improving the comprehensive working performance, reducing the growth rate and reducing the working resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] will (Ti,Nb) 3 SiC 2 The coating is deposited on the surface of the SUS430 stainless steel connector. First prepare (Ti,Nb) 3 SiC 2 Bulk target and purchase commercial SUS430 stainless steel alloy. Use 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper to polish the alloy substrate step by step, and then pass the polished metal connector samples through acetone, alcohol and deionized water respectively. After ultrasonic cleaning for 15 min, dry in air for later use.

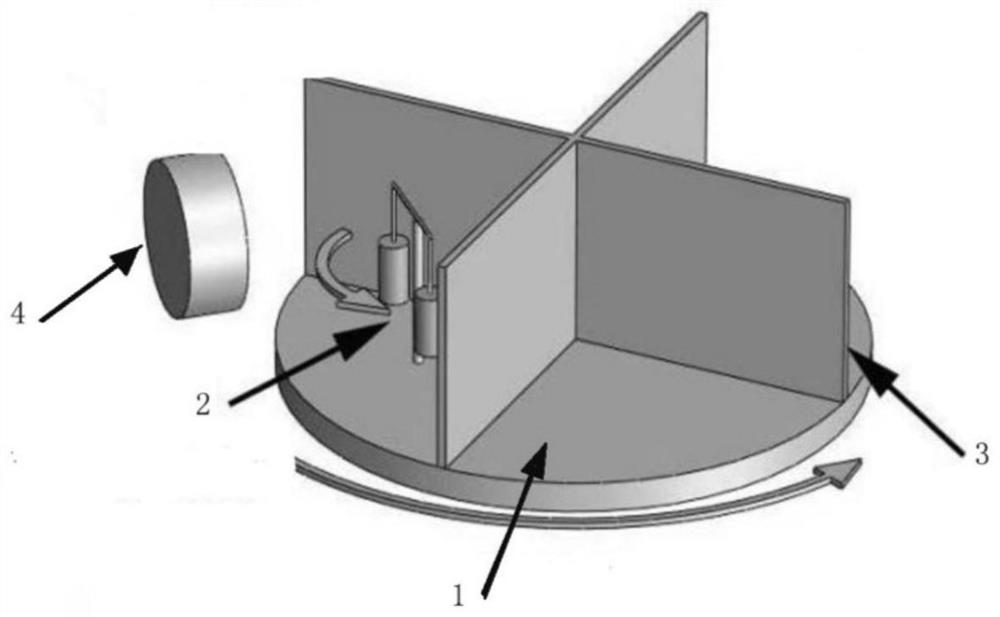

[0036] Coatings were deposited on the surface of the alloy using an arc ion plating apparatus. The arc ion plating device includes a rotary table, the upper surface of the rotary table is provided with a partition, the space above the rotary table is divided into several relatively independent spaces, the sample rack is arranged in the independent space, the column of the sample rack can rotate, and the column Can revolve with the turntable.

[0037] First hang the sample on the s...

Embodiment 2

[0040] Will (Ti,W) 3 SiC 2 The coating is deposited on the surface of the Crofer 22APU stainless steel connector. First prepare (Ti,W) 3 SiC 2 Bulk target and purchased commercial Crofer22APU stainless steel alloy. Use 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper to polish the alloy substrate step by step, and then pass the polished metal connector samples through acetone, alcohol and deionized water respectively. After ultrasonic cleaning for 10 min, dry in air for later use.

[0041] The coating is deposited on the surface of the alloy by using a magnetron sputtering equipment, and the sample is first suspended on the sample holder of the equipment (such as figure 1 shown), the column of the sample can rotate, and the rotating column can revolve with the turntable. Before coating preparation, pre-evacuated to 5×10 -4 Pa to minimize the contamination of residual gas during sputtering. After the vacuum degree required for the experiment was rea...

Embodiment 3

[0044] Ti 3 SiC 2 The coating is deposited on the surface of the Fe-17Cr-0.2Y stainless steel connector. First prepare Ti 3 SiC 2Bulk target and purchased commercial Fe-17Cr-0.2Y stainless steel alloy. Use 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000# metallographic sandpaper to polish the alloy substrate step by step, and then pass the polished metal connector samples through acetone, alcohol and deionized water respectively. After ultrasonic cleaning for 20 min, dry in air for later use.

[0045] The coating is deposited on the surface of the alloy using arc ion plating equipment, and the sample is first suspended on the sample holder of the equipment (e.g. figure 1 shown), the column of the sample can rotate, and the rotating column can revolve with the turntable. Before coating preparation, the vacuum chamber was pre-evacuated to a background vacuum of 5×10 -3 After Pa, a negative pulse bias voltage of 500V was applied to the substrate to perform backsplash cleaning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com