Continuous granulation process equipment for trichlorfon

A process equipment, trichlorfon technology, applied in pesticides, organic chemistry, chemical instruments and methods, etc., can solve the problems of unfavorable scraper shoveling, low production efficiency, lack of pre-crystallization, etc., to save packaging material costs And labor costs, improve production efficiency and sales, the effect of uniform and round particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

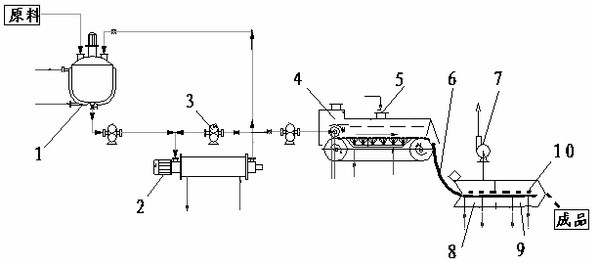

[0022] Such as figure 1 As shown, put 7.2t of trichlorfon material in the insulation kettle, use hot water to insulate the material, control the internal temperature of the trichlorfon material to 70°C, open the bottom material valve, start the feed pump, and control the discharge pump The flow rate is 3m 3 / h, transport the trichlorfon liquid material to the pre-crystallizer, there is a hinged scraper on the internal stirring of the pre-crystallizer, so as to ensure that the material does not accumulate on the wall, and the fluidity of the material is guaranteed, and at the same time, the external circulation pump of the pre-crystallizer is turned on , the control flow is 10 m 3 / h, through forced circulation, heat exchange is enhanced to ensure that the material forms a slurry with crystals in a short period of time, and the partially crystallized trichlorfon material formed by cooling the pre-crystallizer passes through the loop pipeline and returns to the In the insulati...

Embodiment 2

[0024] .Put 7.2t of trichlorfon material in the insulation kettle, use hot water to insulate the material, control the internal temperature of the trichlorfon material to 75°C, open the bottom material valve, start the feed pump, and control the flow of the feed pump 2m 3 / h, transport the trichlorfon liquid material to the pre-crystallizer, there is a hinged scraper on the internal stirring of the pre-crystallizer, so as to ensure that the material does not accumulate on the wall, and the fluidity of the material is guaranteed, and at the same time, the external circulation pump of the pre-crystallizer is turned on , the control flow is 5m 3 / h, through forced circulation, heat exchange is enhanced to ensure that the material forms a slurry with crystals in a short period of time, and the partially crystallized trichlorfon material formed by cooling the pre-crystallizer passes through the loop pipeline and returns to the In the heat preservation kettle, install a viscometer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com