Aluminum silicon carbide high-power LED radiator and preparation method thereof

A LED heat sink, aluminum silicon carbide technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

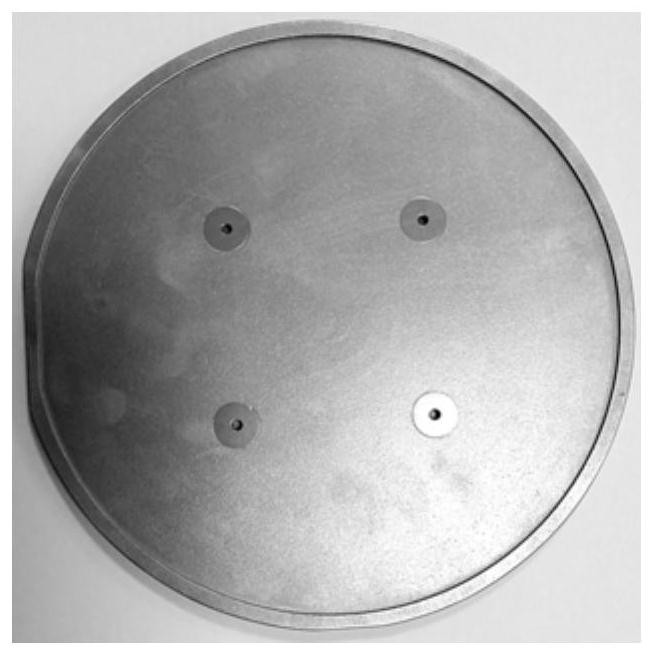

Image

Examples

preparation example Construction

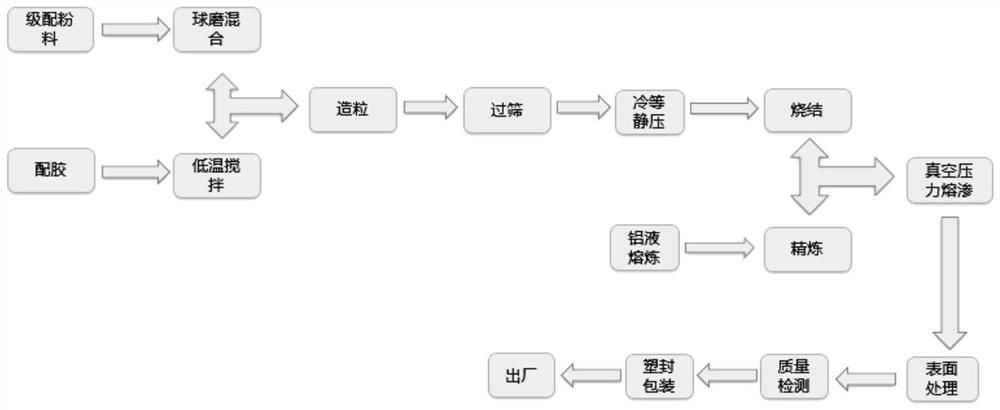

[0056] Specifically, the present invention provides a method for preparing an aluminum silicon carbide high-power LED heat dissipation liner, the specific steps are as follows:

[0057] S1. According to the requirements of technical indicators such as thermal conductivity, dimensional stability, and bending strength of the LED heat dissipation lining board and the principles of heat conduction and bending strength of the microstructure of the aluminum-silicon carbide composite material, the particle gradation design is targeted and customized as follows: The mass ratio of 220#, 100# and 15# is 10:7:3; in order to improve the wettability of aluminum alloy, the contents of Mg and Si are adjusted during the refining process of ZL101A to increase them to 0.4%-0.8% respectively.

[0058] S2. Select silicon carbide particles with corresponding particle size distribution according to the gradation theory, and mix silicon carbide powder with ball milling beads with diameters of 15cm, 8...

Embodiment 1

[0070] The invention provides a method for preparing an aluminum silicon carbide high-power LED radiator, the specific steps are as follows:

[0071] S1. According to the requirements of technical indicators such as thermal conductivity, dimensional stability, and bending strength of the LED heat dissipation lining board and the principles of heat conduction and bending strength of the microstructure of the aluminum-silicon carbide composite material, the particle gradation design is targeted and customized as follows: The mass ratio of 220#, 100# and 15# is 10:7:3; in order to improve the wettability of aluminum alloy, the contents of Mg and Si are adjusted to 0.4% and 0.8% respectively during the refining process of ZL101A.

[0072] S2. Select silicon carbide particles with corresponding particle size distribution according to the gradation theory, and mix silicon carbide powder with ball milling beads with diameters of 15cm, 8cm, and 3cm (the mass ratio of the three kinds of...

Embodiment 2

[0083] The invention provides a method for preparing an aluminum silicon carbide high-power LED radiator, the specific steps are as follows:

[0084] S1. According to the requirements of technical indicators such as thermal conductivity, dimensional stability, and bending strength of the LED heat dissipation lining board and the principles of heat conduction and bending strength of the microstructure of the aluminum-silicon carbide composite material, the particle gradation design is targeted and customized as follows: The mass ratio of 220#, 100# and 15# is 10:7:3; in order to improve the wettability of aluminum alloy, the contents of Mg and Si are adjusted to 0.5% and 0.6% respectively during the refining process of ZL101A.

[0085] S2. Select silicon carbide particles with corresponding particle size distribution according to the gradation theory, and mix silicon carbide powder with ball milling beads with diameters of 15cm, 8cm, and 3cm (the mass ratio of the three kinds of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com