Silicon nitride ceramic part and manufacturing method thereof

A technology of silicon nitride ceramics and a manufacturing method, applied in the field of ceramic materials, can solve the problems of limited density of parts, unacceptable for enterprises, and high cost of raw materials, and achieve the effects of improving efficiency, increasing density and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

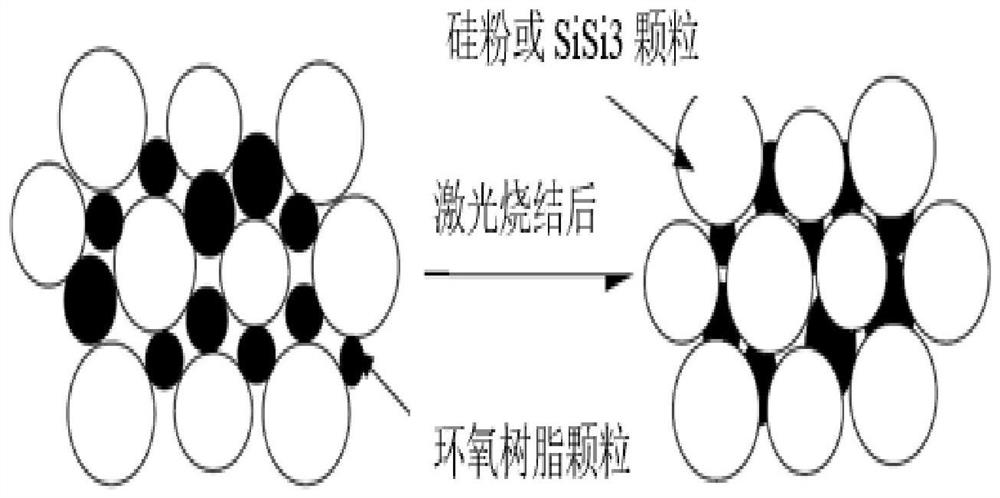

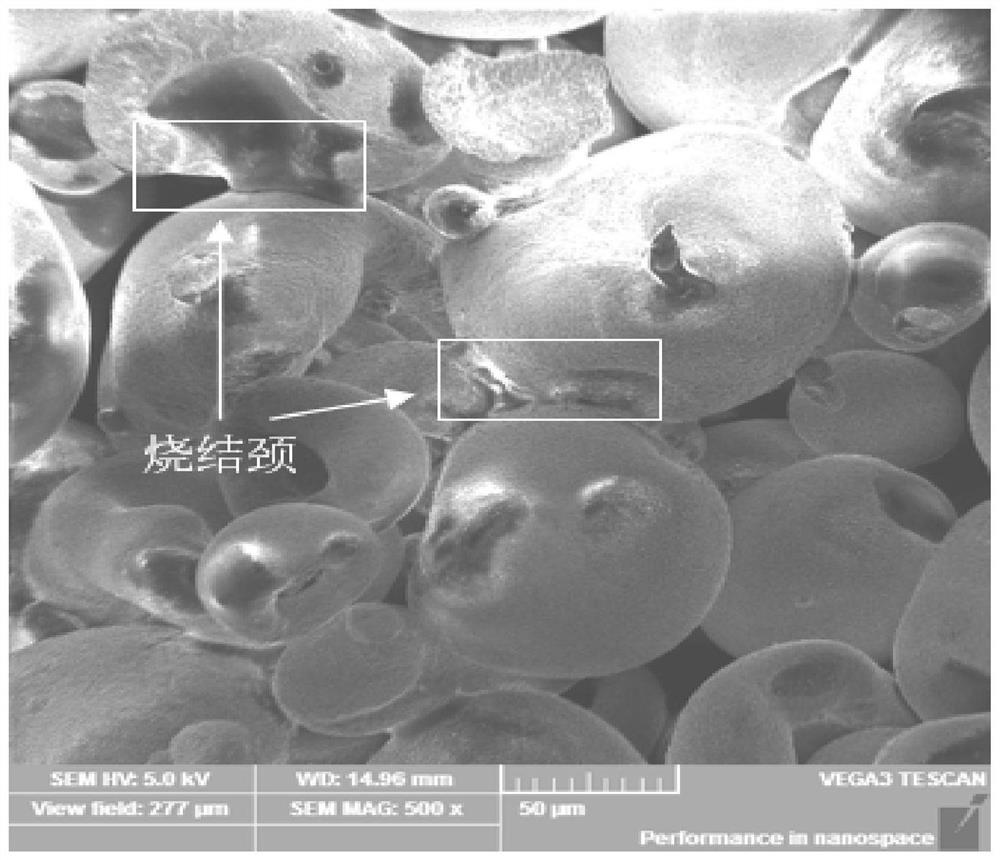

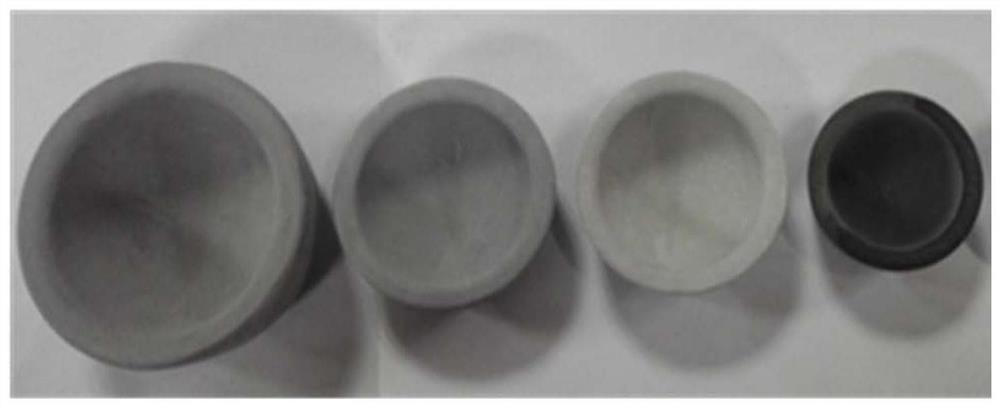

[0056] A silicon nitride (Si 3 N 4 ) A method for manufacturing a ceramic negative spherical part, comprising the following steps:

[0057] (a) 80g of industrial silicon powder with a purity of 99.5% or more and a powder particle size of 5-25μm, and 20g of α-Si with a median particle size of 10±0.5μm 3 N 4 Mix evenly by ball milling, then add 10g of bisphenol A epoxy resin with a particle size of 20-50μm, 1g of magnesia, and 2.5g of zirconia, use the 3D modeling design software catia to design the 3D digital model of the ceramic negative spherical part, and divide it with slices Layer software converts it into STL format and imports it into SLS equipment, and the laser is 60W CO 2 Laser, the preheating temperature is 40°C, the thickness of the single layer is 0.1mm, the scanning distance is 0.1mm, the scanning speed is 1000mm / s, and the relative density of the blank of the part is 30-35%;

[0058] (b) Carry out the first vacuum pressure infiltration impregnation on the gre...

Embodiment 2

[0067] A silicon nitride (Si 3 N 4 ) A method for manufacturing a ceramic negative spherical part, comprising the following steps:

[0068] (a) 50g of industrial silicon powder with a purity of 99.5% or more and a powder particle size of 10-25μm, and 50g of α-Si with a median particle size of 10±0.5μm 3 N 4 Mix evenly by ball milling, then add 15g of bisphenol A epoxy resin with a particle size of 20-50μm, 2g of magnesium oxide, and 3g of zirconia, use the three-dimensional modeling design software pro / E to design the three-dimensional digital model of the ceramic negative spherical part, and slice it The layering software converts it into STL format and imports it into SLS equipment, and the laser is 35W CO 2 Laser, the preheating temperature is 60°C, the thickness of the single layer is 0.2mm, the scanning distance is 0.2mm, the scanning speed is 3000mm / s, and the relative density of the blank of the part is 30-35%;

[0069] (b) Carry out the first vacuum pressure infilt...

Embodiment 3

[0078] A silicon nitride (Si 3 N 4 ) A method for manufacturing a ceramic negative spherical part, comprising the following steps:

[0079] (a) 60g of industrial silicon powder with a purity of 99.5% or more and a powder particle size of 10-25μm, and 40g of α-Si with a median particle size of 10±0.5μm 3 N 4 Mix evenly by ball milling, then add 20g of bisphenol A epoxy resin with a particle size of 20-50μm and 4g of carbon powder, use the 3D modeling design software Solidworks to design the 3D digital model of the ceramic negative spherical part, and use the slice layering software to transfer it Import SLS equipment for STL format, the laser is 50W CO 2 Laser, the preheating temperature is 50°C, the thickness of the single layer is 0.1mm, the scanning distance is 0.1mm, the scanning speed is 3000mm / s, and the relative density of the blank of the part is 30-35%;

[0080] (b) Carry out the first vacuum pressure infiltration impregnation on the green body of the part, put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com