P-isopropylbenzaldehyde and preparation method for synthesizing P-isopropylbenzaldehyde from isopropylbenzene

A technology of cumene and cumene, applied in the field of preparation of p-cumene, can solve the problems of poor process safety, low cost, inability to realize large-scale industrial production, etc., and achieves low cost of process raw materials, Good process selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

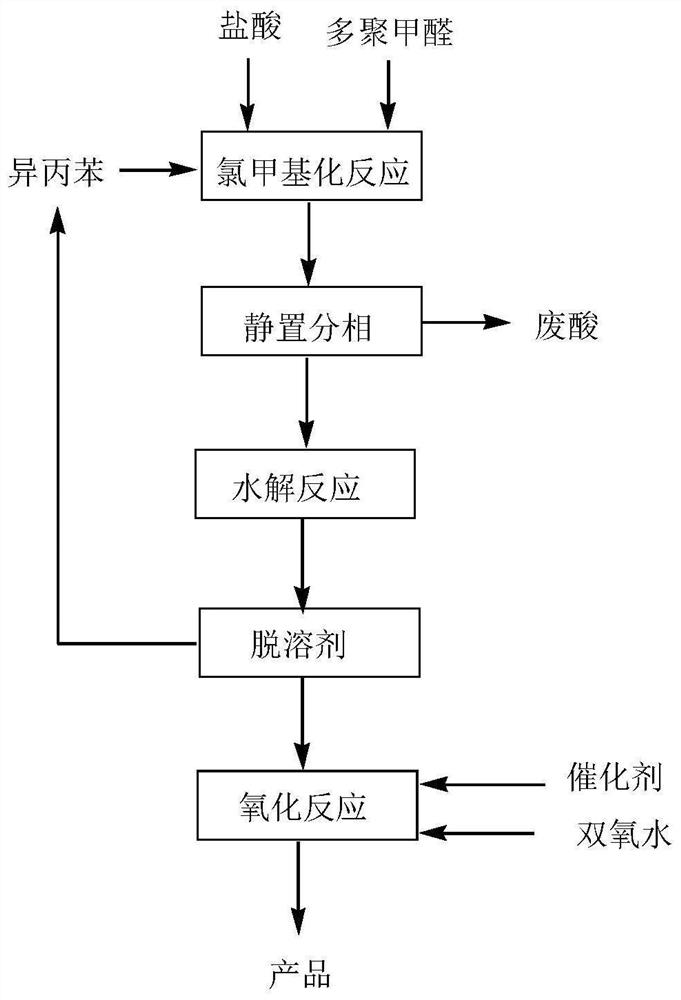

Method used

Image

Examples

Embodiment 1

[0059] A kind of preparation method of synthesizing p-cumyl aldehyde by cumene, comprises the following steps:

[0060] Step 1, chloromethylation reaction

[0061] Add 500kg of cumene and 200g of formaldehyde into a 5000L reaction kettle, raise the temperature to 40°C, then start to add 36.5% hydrochloric acid dropwise, add 2500kg dropwise within 1 hour, the temperature of the system is 70-72°C after the addition, and continue to heat up to 80°C, Maintain the temperature and react for 1 hour. After the reaction is completed, stand still and separate the phases to obtain an organic phase and an inorganic phase. The inorganic phase is waste acid, which can be recycled and reused;

[0062] Step two, hydrolysis reaction

[0063] Add 100kg of sodium hydroxide, 7000kg of pure water, and 27.5kg of cetyltrimethylammonium bromide into a 10,000L reactor, mix well to form a hydrolysis solution, then add the organic phase obtained in step 1, and heat up to 80 ℃, then react for 6 hours, ...

Embodiment 2

[0067] Step 1, chloromethylation reaction

[0068] Add 500kg of cumene and 200g of paraformaldehyde into a 5000L reaction kettle, raise the temperature to above 40°C, then start to add 36.5% hydrochloric acid dropwise, add 2500kg dropwise within 1h, after the addition, the system temperature is 70-72°C, and continue to heat up to 80°C, maintain the temperature for 1 hour. After the reaction, stand still and separate the phases to obtain an organic phase and an inorganic phase. The inorganic phase is waste acid, which can be recycled and reused;

[0069] Add 100kg of sodium hydroxide, 7000kg of pure water, and 27.5kg of cetyltrimethylammonium bromide into a 10,000L reactor, mix well to form a hydrolysis solution, then add the organic phase obtained in step 1, and heat up to 80 ℃, then react for 6 hours, after the reaction is completed, stand still and separate the phases, wash the organic phase once with 250kg of clean water to obtain the hydrolyzed organic phase, and neutraliz...

Embodiment 3

[0073] Step 1, chloromethylation reaction

[0074] Add 500kg of cumene and 200g of paraformaldehyde into a 5000L reaction kettle, raise the temperature to 40°C, then start to add 36.5% hydrochloric acid dropwise, add 2500kg dropwise within 1 hour, the temperature of the system is 70-72°C after adding, and continue to heat up to 80°C ℃, maintain the temperature for 1 hour, after the reaction, stand still and separate the phases to obtain an organic phase and an inorganic phase, and the inorganic phase is waste acid, which can be recycled and reused;

[0075] Step two, hydrolysis reaction

[0076] Add 100kg of sodium carbonate, 7000kg of pure water, and 27.5kg of cetyltrimethylammonium bromide into a 10,000L reactor, mix well to form a hydrolysis solution, then add the organic phase obtained in step 1, and heat up to 80°C under stirring , and then reacted for 6 hours. After the reaction was completed, stand still and separate the phases. The organic phase was washed once with 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com