Amidoxime functional feather fiber adsorption material as well as preparation method and application thereof

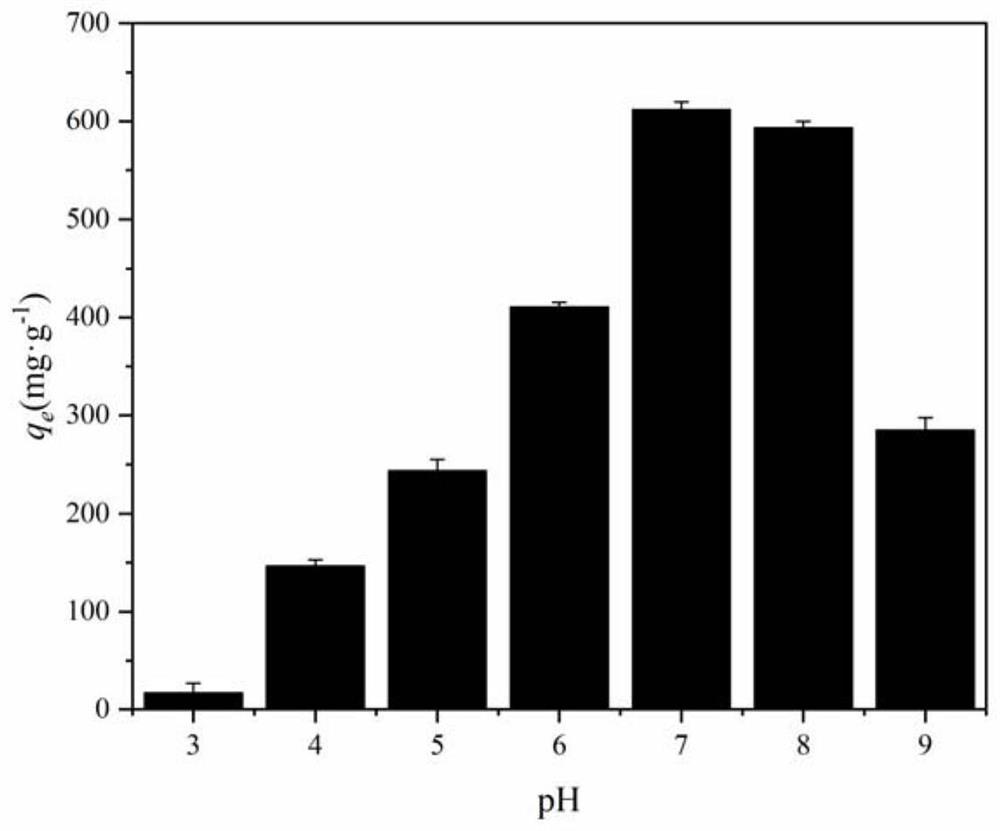

A feather fiber and amidoxime-based technology is applied in the field of preparation of seawater uranium extraction adsorption materials, which can solve the problems of difficult practical application operation, complex preparation process, and low adsorption efficiency, and achieve low raw material prices, simple application and recovery operations, and The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

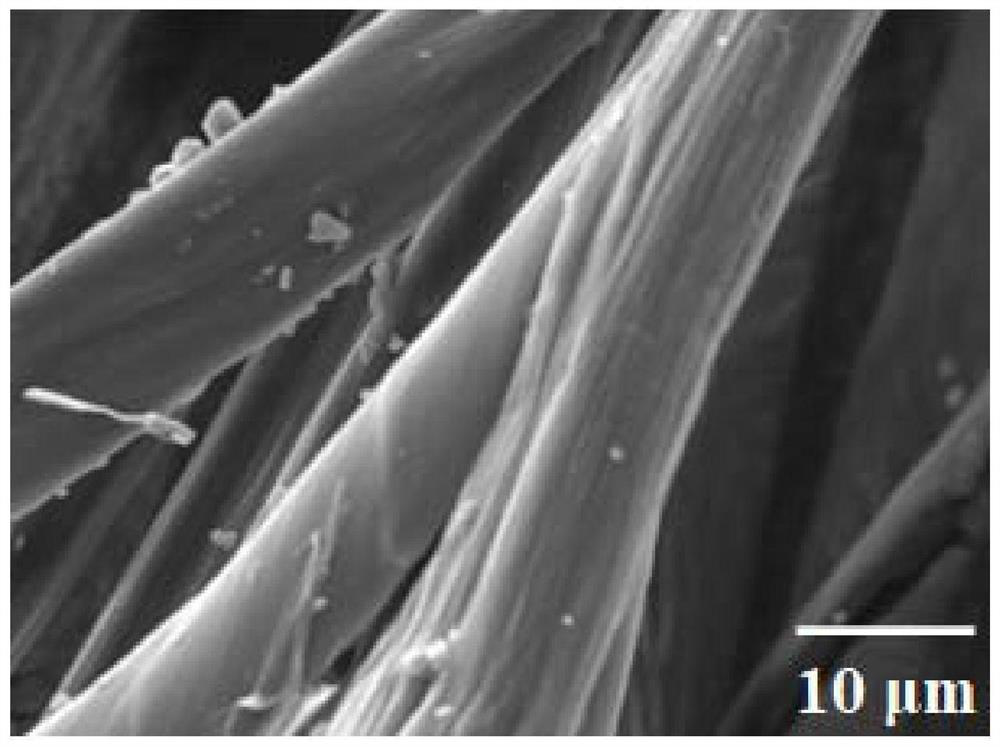

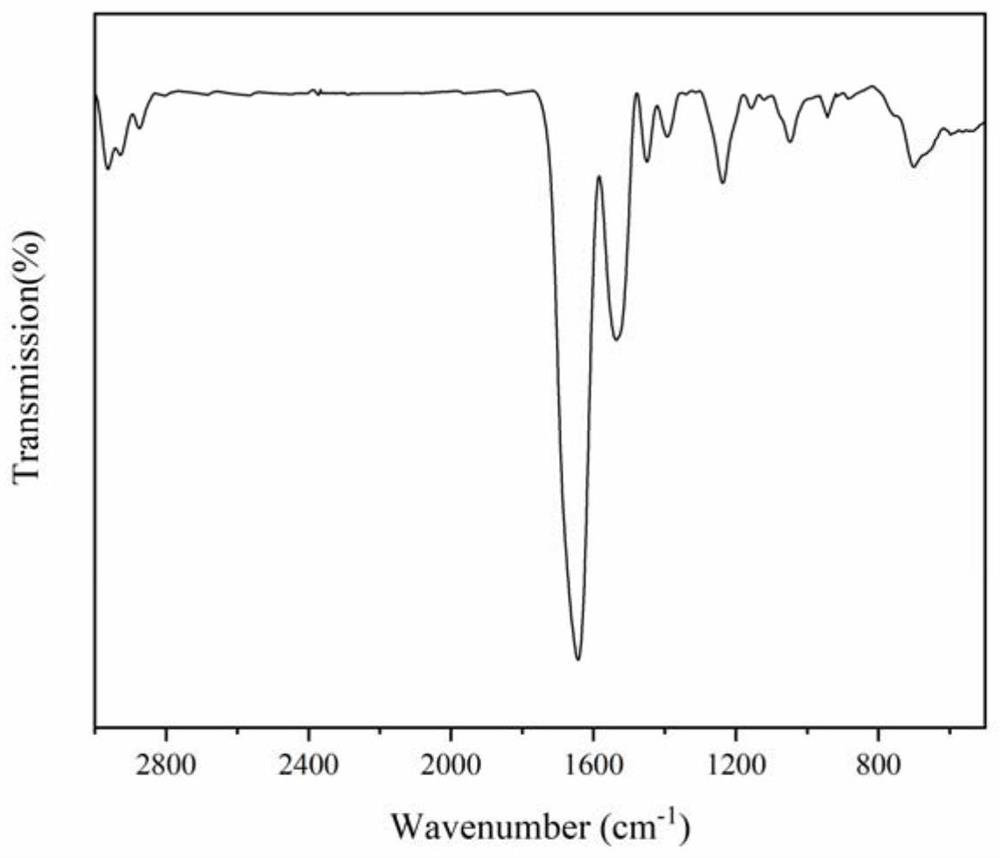

[0039] A kind of preparation method of amidoxime functionalized feather fiber adsorption material is as follows:

[0040] First, the waste feather fibers are sorted to remove impurities, and then the feather fibers are preliminarily washed with 1:40 water. After washing, a degreasing agent is added to degrease the feather fibers. Removes residual degreaser from feather fibers. Add 5 g of washed feather fibers and 100 mL of sodium carbonate solution (w / w=10%) into a 250 mL flask, and soak for 15 min at room temperature to expose the active hydroxyl groups in the feather fibers and deprotonate them under alkaline conditions. Then 10 mL of acrylonitrile was added and reacted at 40° C. for 3 h. Then, unreacted acrylonitrile is removed with 50% ethanol aqueous solution, and finally the obtained feather fiber is washed with water, and dried to constant weight at 40° C. to obtain cyano functionalized feather fiber. Add 5 g of cyano-functionalized feather fiber to 160 mL of hydroxyl...

Embodiment 2

[0042] A kind of preparation method of amidoxime functionalized feather fiber adsorption material is as follows:

[0043] First, the waste feather fibers are sorted to remove impurities, and then the feather fibers are preliminarily washed with 1:40 water. After washing, a degreasing agent is added to degrease the feather fibers. Removes residual degreaser from feather fibers. Add 5 g of washed feather fibers and 100 mL of sodium carbonate solution (w / w=5%) into a 250 mL flask, and soak for 30 min at room temperature to expose the active hydroxyl groups in the feather fibers and deprotonate them under alkaline conditions. Then 5 mL of acrylonitrile was added and reacted at 50° C. for 2 h. Then, unreacted acrylonitrile is removed with 50% ethanol aqueous solution, and finally the obtained feather fiber is washed with water, and dried to constant weight at 40° C. to obtain cyano functionalized feather fiber. Add 5 g of cyano-functionalized feather fiber to 100 mL of hydroxylam...

Embodiment 3

[0045] A kind of preparation method of amidoxime functionalized feather fiber adsorption material is as follows:

[0046] First, the waste feather fibers are sorted to remove impurities, and then the feather fibers are preliminarily washed with 1:40 water. After washing, a degreasing agent is added to degrease the feather fibers. Removes residual degreaser from feather fibers. Add 5 g of washed feather fibers and 100 mL of sodium carbonate solution (w / w=20%) into a 250 mL flask and soak for 20 min at room temperature to expose the active hydroxyl groups in the feather fibers and deprotonate them under alkaline conditions. Then 8 mL of acrylonitrile was added and reacted at 30° C. for 4 h. Then, unreacted acrylonitrile is removed with 50% ethanol aqueous solution, and finally the obtained feather fiber is washed with water, and dried to constant weight at 40° C. to obtain cyano functionalized feather fiber. Add 5 g of cyano-functionalized feather fiber to 200 mL of hydroxylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com