Vacuum brazing method for dissimilar metal of concrete machinery

A technology of concrete machinery and dissimilar metals, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of matrix and hard alloy volume deformation, stress, and affecting the quality of weldments, so as to ensure production efficiency and ensure overall The effect of mass, overall thermal stress and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a vacuum brazing method for spectacle plates and alloys of concrete machinery, comprising the following steps:

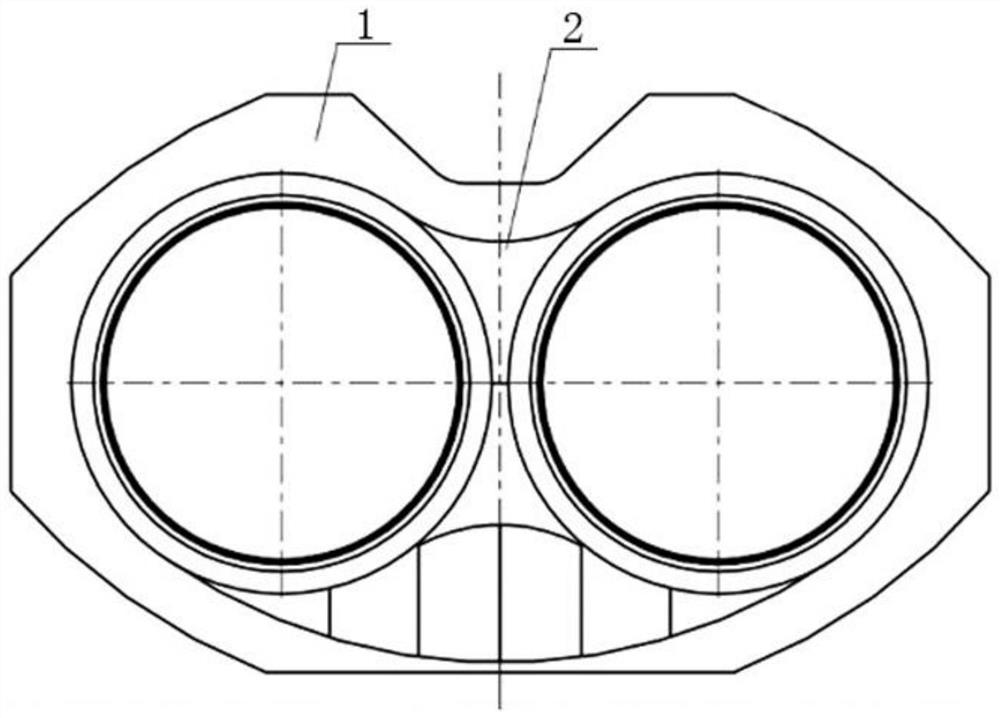

[0034] The spectacle plate is made of carbon steel plate, and the alloy groove is machined after blanking, which is used as the weldment matrix 1, such as figure 1 shown;

[0035] The selected cemented carbide block 2 is pressed and formed by a mold according to the required shape, then sintered, and trimmed to the required shape and size by machining, and placed in the alloy groove; figure 1 shown;

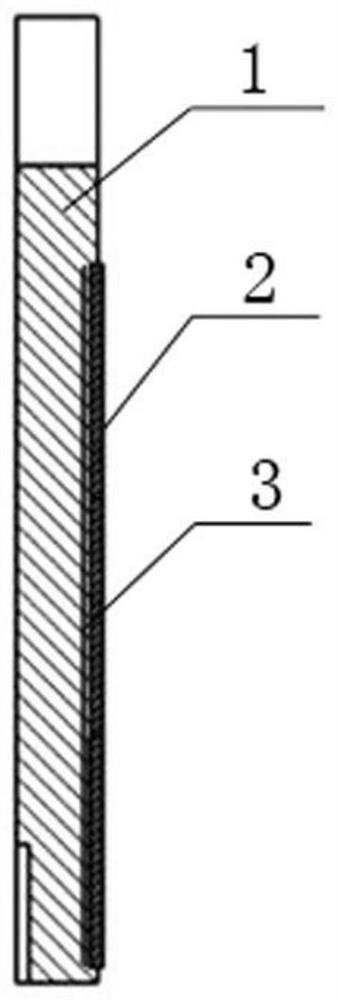

[0036] Select a 0.3mm thick oxygen-free copper sheet 3 and cut it according to the required shape and size by punching or laser equipment, and place the oxygen-free copper sheet 3 between the substrate 1 and the alloy block 2, such as figure 2 As shown, paste-like copper-based solder is filled between the alloy blocks 2 and the joint gap between the alloy block 2 and the substrate 1, and assembled into a weldment;

[0037] Place the ...

Embodiment 2

[0042] This embodiment provides a vacuum brazing method for a cutting ring of a concrete machine and an alloy, comprising the following steps:

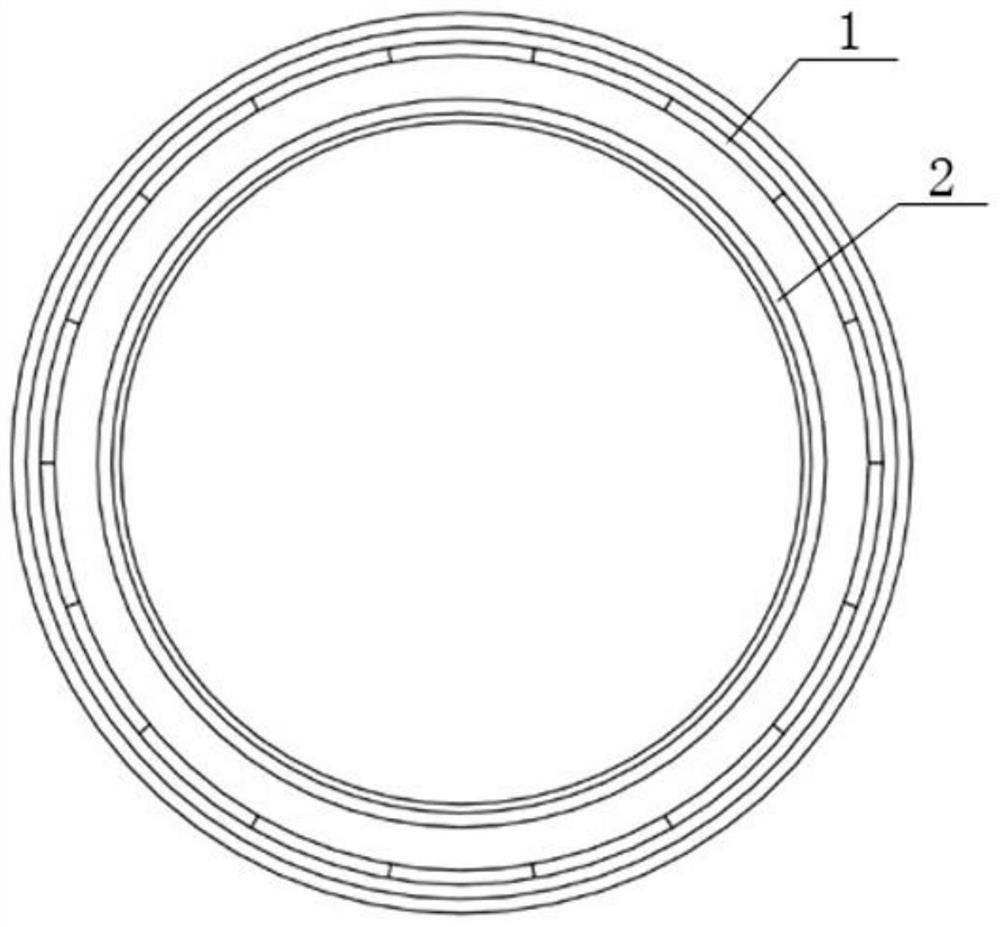

[0043] The cutting ring is made of carbon steel profile, and the alloy groove is machined after blanking, which is used as the weldment matrix 1, such as image 3 shown;

[0044] The selected cemented carbide block 2 is pressed and formed by a mold according to the required shape, then sintered, and trimmed to the required shape and size by machining, and placed in the alloy groove; image 3 shown;

[0045] Select a 0.3mm thick oxygen-free copper sheet 3 and cut it according to the required shape and size by punching or laser equipment, and place the oxygen-free copper sheet 3 between the substrate 1 and the alloy block 2, such as Figure 4 As shown, paste-like copper-based solder is filled between the alloy blocks 2 and the joint gap between the alloy block 2 and the substrate 1, and assembled into a weldment;

[0046] Place the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com