Formula and manufacturing process of outer-layer puncture-proof plating of environment-friendly metal barrel

A metal barrel and coating technology, which is applied in metal material coating technology, electrolytic inorganic material coating, coating, etc., can solve the problems of poor corrosion resistance and high temperature resistance of the anti-stab coating, and achieve heat resistance and corrosion resistance Good, anti-stab impact strength, good for storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

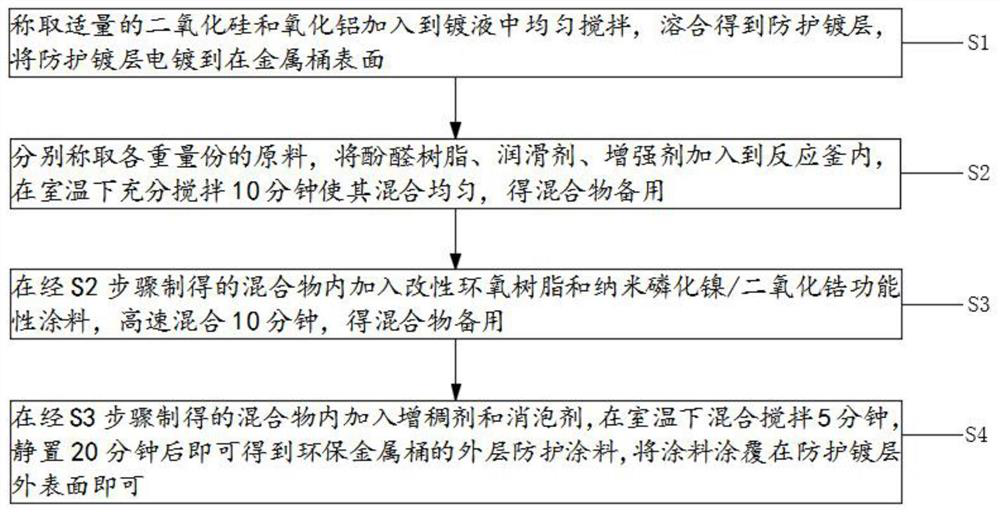

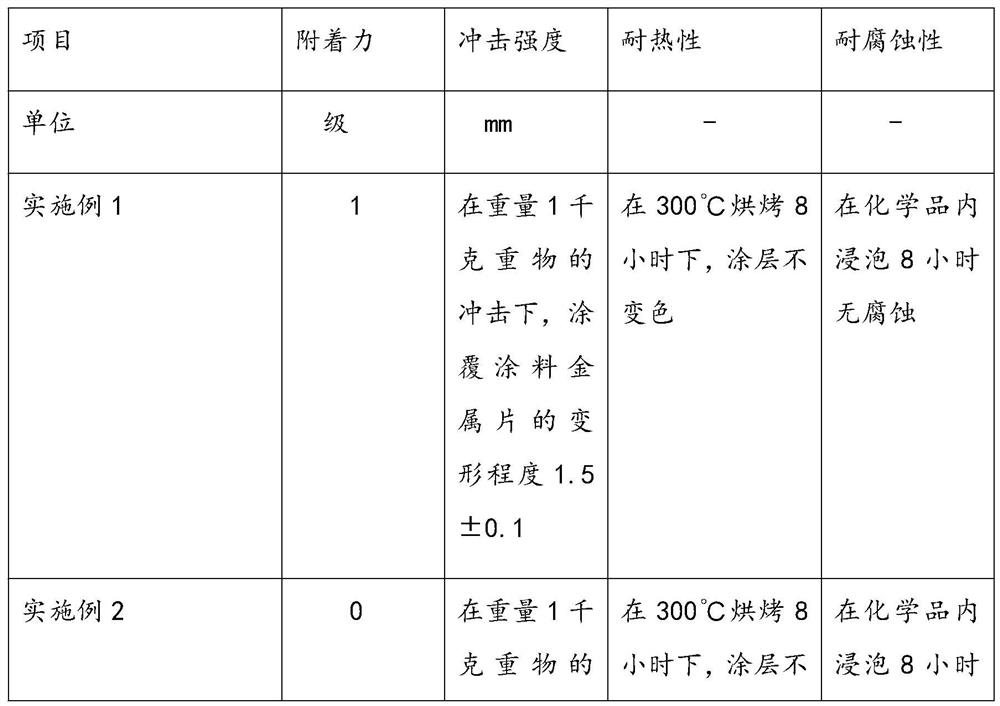

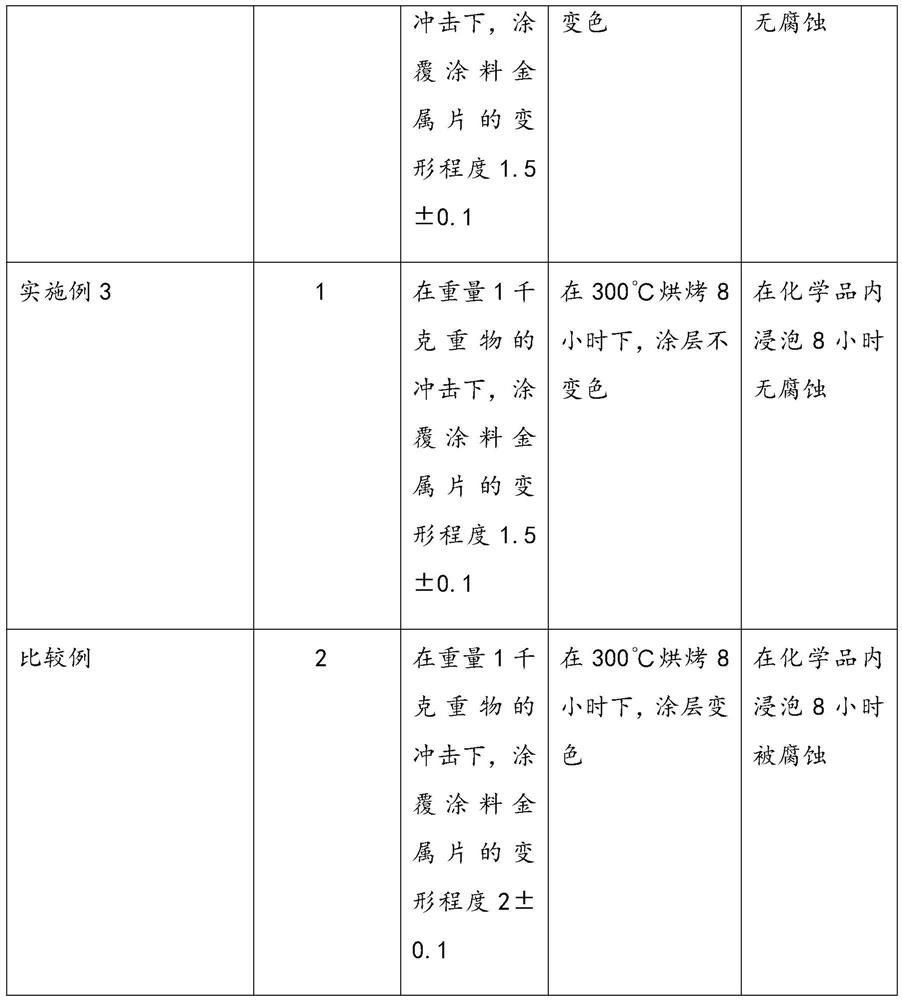

[0032] like figure 1 As shown, an outer anti-stab coating formula and manufacturing process of an environment-friendly metal barrel proposed by an embodiment of the present invention, the outer anti-stab coating of the environmental-friendly metal barrel includes a protective coating and a protective coating coated on the outer surface of the protective coating , the protective coating includes the following raw materials by weight: 35 parts of phenolic resin, 2 parts of lubricant, 1.5 parts of reinforcing agent, 28 parts of modified epoxy resin, 30 parts of nano-nickel phosphide / zirconia functional coating, thickened 2 parts of agent, 1.5 parts of defoamer.

[0033] In some embodiments, the protective coating is silicon dioxide and aluminum oxide, and the mass ratio of silicon dioxide and aluminum oxide is 1:2.

[0034] In some embodiments, the reinforcing agent is one of reduced iron powder, copper oxide powder, and quartz powder. The lubricant is one of colloidal molybdenu...

Embodiment 2

[0051] like figure 1 As shown, an outer anti-stab coating formula and manufacturing process of an environment-friendly metal barrel proposed by an embodiment of the present invention, the outer anti-stab coating of the environmental-friendly metal barrel includes a protective coating and a protective coating coated on the outer surface of the protective coating , the protective coating includes the following raw materials in parts by weight: 40 parts of phenolic resin, 1.5 parts of lubricant, 1 part of reinforcing agent, 27 parts of modified epoxy resin, 28 parts of nano-nickel phosphide / zirconia functional coating, thickened 1.5 parts of agent, 1 part of defoamer.

[0052] In some embodiments, the protective coating is silicon dioxide and aluminum oxide, and the mass ratio of silicon dioxide and aluminum oxide is 1:2.

[0053] In some embodiments, the lubricant is one of colloidal molybdenum disulfide and colloidal graphite powder, and the reinforcing agent is one of reduced...

Embodiment 3

[0070] like figure 1 As shown, an outer anti-stab coating formula and manufacturing process of an environment-friendly metal barrel proposed by an embodiment of the present invention, the outer anti-stab coating of the environmental-friendly metal barrel includes a protective coating and a protective coating coated on the outer surface of the protective coating , the protective coating includes the following raw materials by weight: 47 parts of phenolic resin, 1 part of lubricant, 0.5 part of reinforcing agent, 25 parts of modified epoxy resin, 25 parts of nano-nickel phosphide / zirconia functional coating, thickened 1 part of antifoaming agent and 0.5 part of antifoaming agent.

[0071] In some embodiments, the protective coating is silicon dioxide and aluminum oxide, and the mass ratio of silicon dioxide and aluminum oxide is 1:2.

[0072] In some embodiments, the lubricant is one of colloidal molybdenum disulfide and colloidal graphite powder, and the reinforcing agent is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com