Spray type detergent

A technology of detergents and additives, applied in the direction of detergent composition, detergent compounding agent, surface active detergent composition, etc., can solve problems such as damage to clothing fibers, aging of clothing fabrics, lack of spray detergent, etc., to achieve The effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

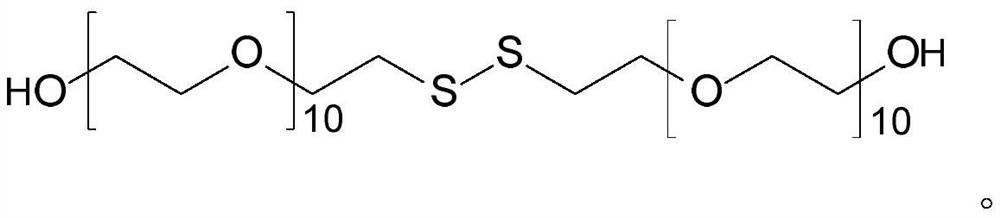

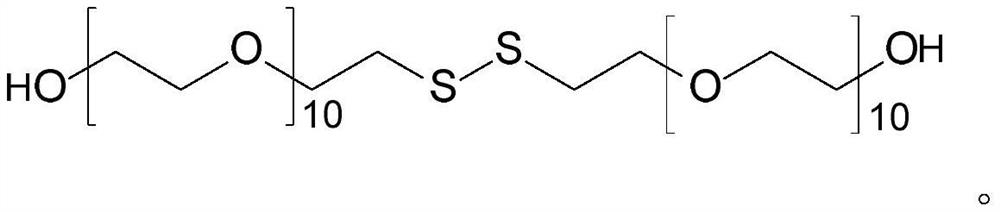

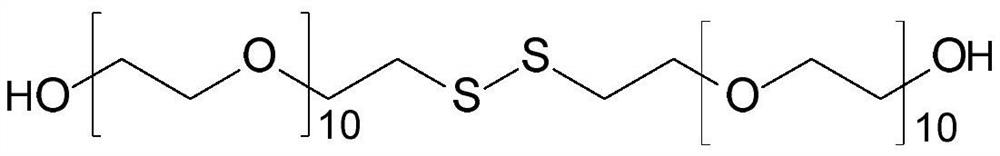

[0030] A spray detergent, calculated in parts by weight, comprising 5 parts of disulfide-coupled polyethylene glycol-modified protease, 5 parts of disulfide-coupled polyethylene glycol-modified cellulase, N,N'-dilauroyl 5 parts of sodium ethylenediamine dipropionate, 15 parts of bentonite, 8 parts of zeolite powder, 3 parts of hyaluronic acid and 60 parts of deionized water.

[0031] The method for modifying protease / cellulase with disulfide-coupling polyethylene glycol is as follows: add protease / cellulase, disulfide-coupling polyethylene glycol and sodium citrate buffer to the reaction kettle in sequence, and stir the reaction at 60°C 1 hour, vested.

Embodiment 2

[0033] A spray detergent, calculated in parts by weight, comprising 10 parts of disulfide-coupled polyethylene glycol modified catalase, 10 parts of disulfide-coupled polyethylene glycol modified mannanase, cocoyl glycine 4 parts of potassium, 5 parts of fatty alcohol ether sodium sulfate, 20 parts of bentonite, 15 parts of zeolite powder, 4 parts of chitosan, 4 parts of sodium alginate and 80 parts of deionized water.

[0034] The method of disulfide-coupled polyethylene glycol modified compound enzyme is: add catalase / mannanase, disulfide-coupled polyethylene glycol and sodium citrate buffer to the reaction kettle in sequence, and stir at 100°C Reaction for 3 hours, vested.

Embodiment 3

[0036] A spray detergent, calculated in parts by weight, comprising 5 parts of disulfide-coupled polyethylene glycol modified protease, 5 parts of disulfide-coupled polyethylene glycol modified catalase and disulfide-coupled polyethylene glycol 5 parts of modified mannanase, 2 parts of N,N'-dilauroyl ethylenediamine dipropionate sodium, 2 parts of potassium cocoyl glycinate, 2 parts of cocamidopropyl hydroxysultaine, 17 parts of bentonite 10 parts of zeolite powder, 2 parts of hyaluronic acid, 2 parts of chitosan, 1 part of sodium alginate and 70 parts of deionized water.

[0037] The method of disulfide-coupled polyethylene glycol modified compound enzyme is as follows: add protease / catalase / mannanase, disulfide-coupled polyethylene glycol and sodium citrate buffer to the reaction kettle in sequence, Under stirring reaction for 2 hours, vested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com