Cyanoacrylate medical adhesive and preparation method thereof

A technology of cyanoacrylate and n-butyl cyanoacrylate is applied in the fields of high-performance tissue adhesives, cyanoacrylate medical adhesives and their preparation, and achieves strong bactericidal properties, fast bonding speed and strong adhesion. combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

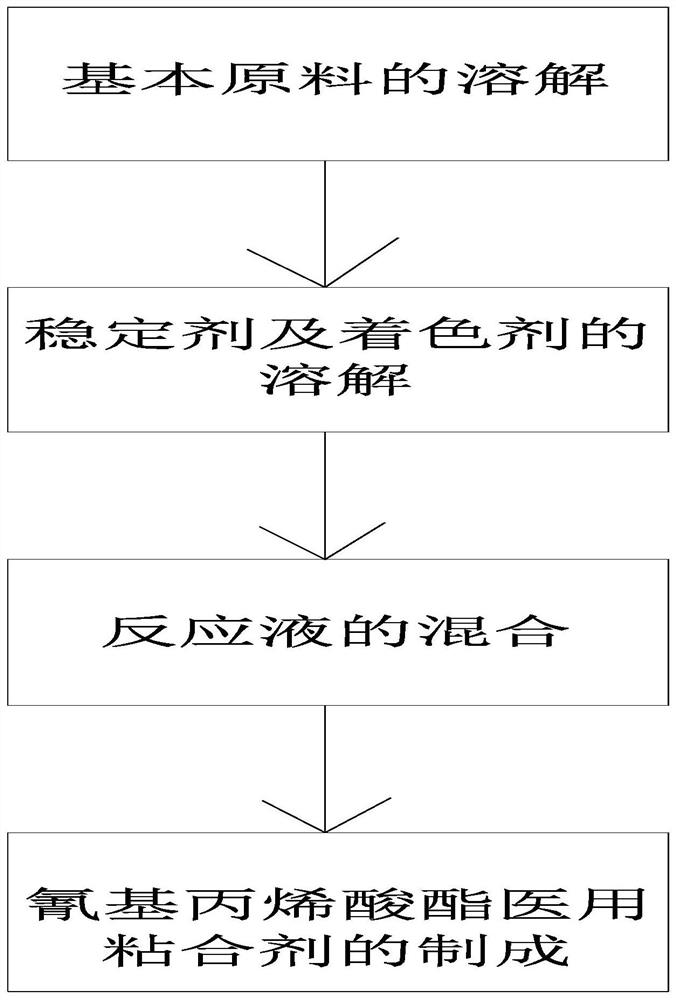

[0052] Further, a preparation method of cyanoacrylate medical adhesive, the specific preparation steps are as follows:

[0053] (1) Dissolution of basic raw materials:

[0054] Weigh each component by mass ratio;

[0055] First, divide α-n-butyl cyanoacrylate into 3 equal parts, take one of them, and add it to the reactor;

[0056] Then, add weighed tributyl citrate, hydroxypropyl methacrylate, sebacate, tannic acid and thickener to the reactor in order; stir at room temperature and at a constant stirring rate , until it dissolves and disperses, and then save it for later use;

[0057] (2) Dissolution of stabilizers and colorants:

[0058] Get one of the remaining two equal parts of n-butyl cyanoacrylate, add it to another reactor, then add a weighed stabilizer, stir at room temperature and at a constant stirring rate until it reaches dissolve;

[0059] Then add the weighed coloring agent, and stir at room temperature and at a constant stirring rate until it dissolves, an...

Embodiment 1

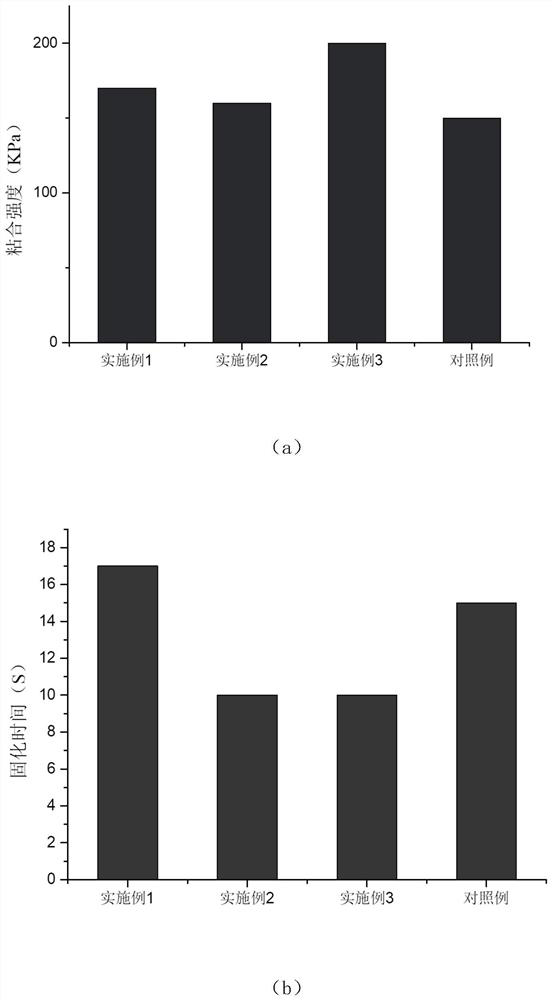

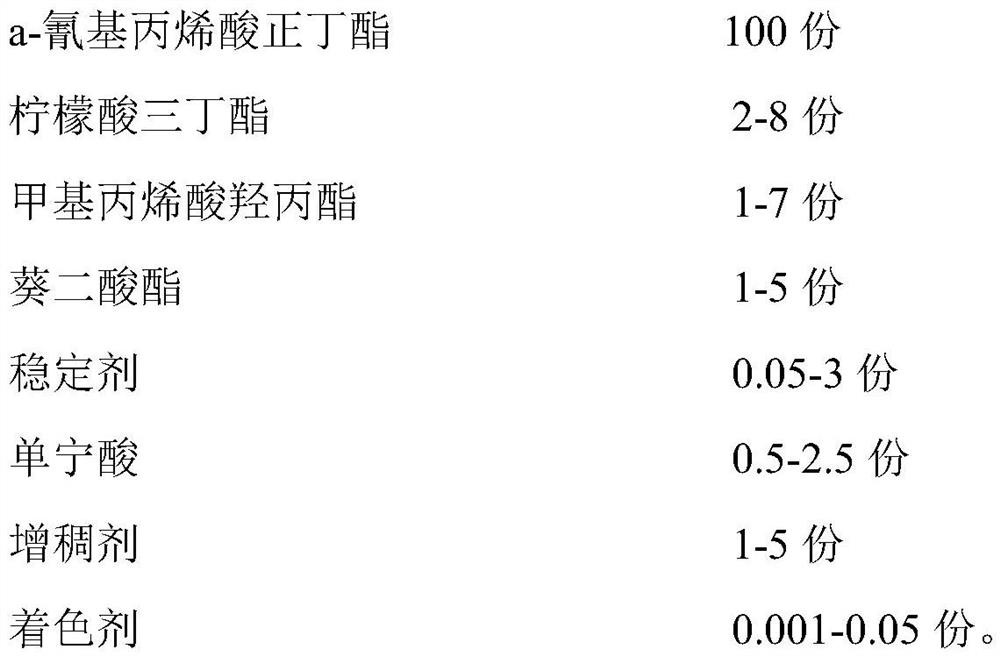

[0067] Accurately weigh 100 parts of n-butyl α-cyanoacrylate (reference material), 5 parts of tributyl citrate, 1 part of hydroxypropyl methacrylate, 3.6 parts of sebacate, (stabilizer) to 0.3 part of quinone, 0.5 part of tannic acid, 1 part of polybutylcyanoacrylate (thickener), 0.005 part of D&C purple dye No. 2 (colorant) and fully stirred to prepare cyanoacrylate medical glue, And use it for 180-degree tensile strength test and curing test; the results show that its adhesive strength is about 170kpa, and the curing time is about 17s.

Embodiment 2

[0069] Accurately weigh 100 parts of n-butyl α-cyanoacrylate (reference material), 5 parts of tributyl citrate, 7 parts of hydroxypropyl methacrylate, 3.6 parts of sebacate, (stabilizer) to 0.08 part of methoxyphenol, 0.05 part of p-toluenesulfonic acid, 1.5 part of tannic acid, 5 parts of (thickener) polylactic acid, 0.005 part of colorant and fully stirred to prepare cyanoacrylate medical glue, and carried out 180 Tensile strength test and curing test; the results show that the bonding strength is 160kpa, and the curing time is about 10s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com