Nitrogen-rich biomass-based activated carbon with hierarchical pore microchannel structure and application thereof

A technology based on microchannel structure and activated carbon, which is applied in the field of porous carbon materials, can solve the problems of low nitrogen doping, microchannel structure damage, and low sulfur storage capacity, and achieve high nitrogen doping and excellent desulfurization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Specifically, nitrogen-rich biomass-based activated carbon with hierarchical porous microchannel structure is prepared by the following method:

[0034] A. Place biomass, nitrogen source and activator in water, mix well, then dry, grind and sieve to obtain a solid mixture; the nitrogen source is melamine cyanurate or melamine-containing cyanurate nitrogen source mixture;

[0035]B. The solid mixture obtained in step A is heated to 650-950° C. for calcination under an inert atmosphere, and the calcined product is washed and dried to form a nitrogen-rich biomass-based activated carbon with a multi-level porous microchannel structure.

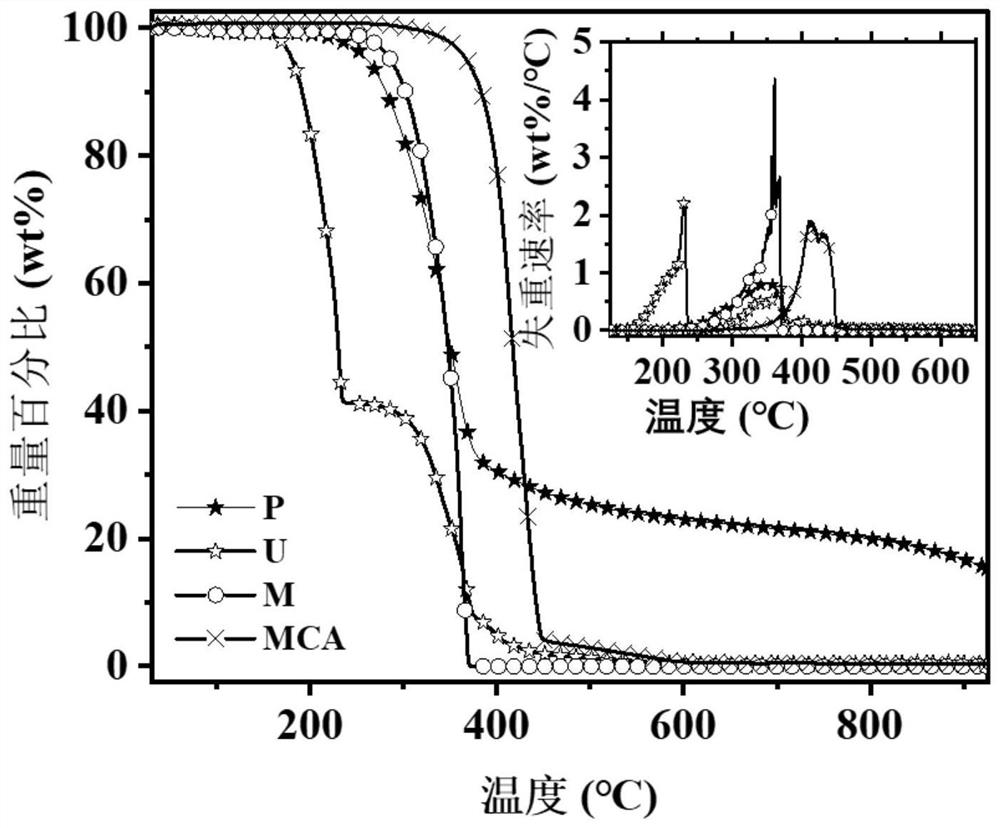

[0036] The present invention first studies the pyrolysis characteristics of biomass, common nitrogen sources (urea and melamine, etc.) and melamine cyanurate (MCA), and finds that the main thermal decomposition temperature (380°C to 450°C) of MCA is higher than that of common Nitrogen source urea (150-240°C) and melamine (300-380°C) are hi...

Embodiment 1

[0052] Take 65.4g of wood chips with a particle size of 40 mesh and 32.7g of potassium hydroxide in 250mL of deionized water and stir for 0.5 hours, then dry the formed uniform cloudy liquid at 105°C for 24 hours to obtain a solid mixture; grind the dried solid mixture After a 40-mesh sieve, heat it to 800°C at a heating rate of 10°C / min in a tube furnace and keep it for 2 hours. The calcination atmosphere is a nitrogen atmosphere, and the nitrogen flow rate is 980mL / min; After drying, pass through a 200-mesh sieve to obtain the product YC-0.5-0(8).

Embodiment 2

[0054] Take 49g of wood chips with a particle size of 40 mesh and 49g of melamine cyanurate in 250mL of deionized water and stir for 0.5 hours, then dry the formed uniform cloudy liquid at 105°C for 24h to obtain a solid mixture; grind the dried solid mixture After passing through a 40-mesh sieve, heat it to 800°C at a heating rate of 10°C / min in a tube furnace and keep it for 2 hours. The calcination atmosphere is a nitrogen atmosphere, and the nitrogen flow rate is 980mL / min; the calcined product is washed with deionized water to Dry after neutralization, and pass through a 200-mesh sieve to obtain the product YC-0-1(8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com