Production device suitable for electronic-grade ammonia gas and ammonia water and production method thereof

A production device and production method technology, applied in the field of electronic-grade ammonia and ammonia water production devices, to achieve the effects of reducing production costs, improving the degree of purification, and saving cooling loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

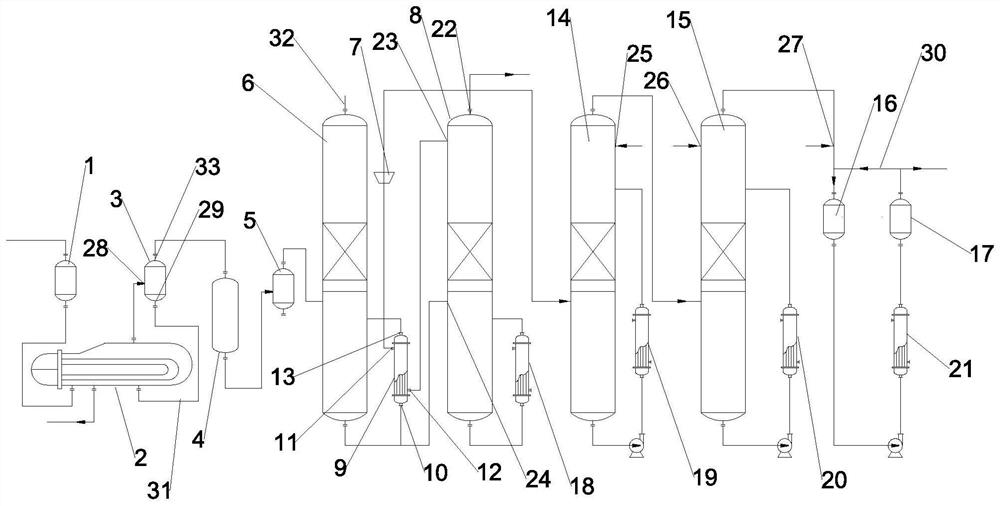

[0038] combined with figure 1 , this embodiment provides a production device suitable for electronic grade ammonia and ammonia water, including an evaporator 2, a gas-liquid separator 3, an adsorption device 4, a first rectification device 6, and a second rectification device 8 connected in sequence , the first washing device 14, the second washing device 15, the absorption device 16 and the filtering device 17; wherein, a thermal coupling device 9 is arranged between the first rectification device 6 and the second rectification device 8, so The second rectifying device 8 has a tower top gas outlet 22, a first inlet 23 and a second inlet 24, and the thermal coupling device 9 has a liquid ammonia inlet 10, a hot gas inlet 11, a hot gas outlet 13 and a liquid ammonia outlet 12, so The liquid ammonia inlet 10 communicates with the bottom of the first rectifying device 6, the hot gas inlet 11 communicates with the gas outlet 22 at the top of the second rectifying device 8, and the...

Embodiment 2

[0043] combined with figure 1 , a production device suitable for electronic-grade ammonia and ammonia water in this embodiment, compared with the technical solution of Embodiment 1, also includes a filter 1, the filter 1 has an inlet and an outlet, and the filter 1 The inlet of the filter 1 is used to receive industrial grade liquid ammonia, and the outlet of the filter 1 communicates with the evaporator 2 . The gaseous ammonia gas treated by the evaporator 2 enters the gas-liquid separator 3 through the third inlet through the pipeline, and the liquid separated by the gas-liquid separator 3 returns to the evaporator 2 through the corresponding return port 29 through the return pipe 31 , to carry out re-evaporation treatment to realize the recycling of materials; and the gas separated by the gas-liquid separator 3 enters the adsorption device 4 through the gas outlet 33 through the pipeline.

[0044] In practice, the gas-liquid separator 3 has a third inlet 28, a gas outlet 3...

Embodiment 3

[0046] combined with figure 1 , a production device suitable for electronic-grade ammonia and ammonia water in this embodiment, compared with the technical solution in Embodiment 1 or 2, also includes a gas purifier 5, and the gas purifier 5 has an air inlet and an outlet Gas port, the gas inlet of the gas purifier 5 is connected with the adsorption device 4 , and the gas outlet of the gas purifier 5 is connected with the first rectifying device 6 . This setting can further purify the ammonia gas and improve the purification degree of the ammonia gas.

[0047] In practice, the gas purifier 5 is provided with membranes of different particle sizes, such as 30nm and 10nm membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com