Method for removing acetic acid in disperse red dye wastewater

A dye wastewater and disperse red technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve problems such as secondary pollution of sulfuric acid, increase esterification rate, increase reaction speed, increase The effect of esterification reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

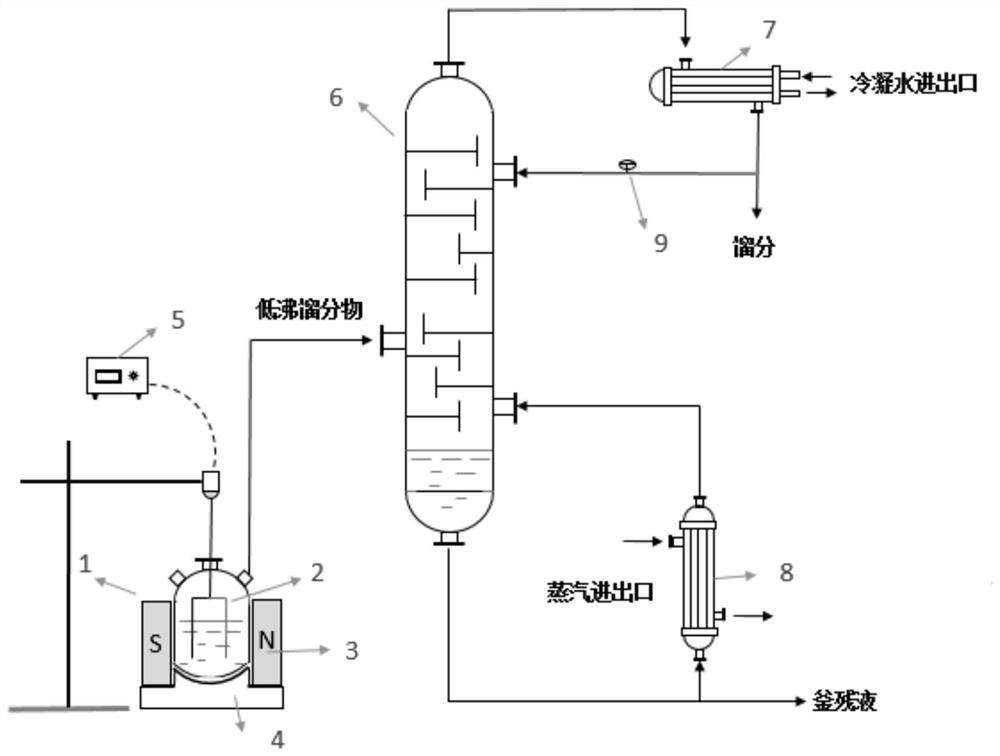

[0021] Such as figure 1 As shown, a cutting coil with stirring function is installed in the reactor, and one end of the coil is connected by a wire to form a closed loop. The reactor is equipped with a magnetic pole, and the two magnetic poles are connected by a wire, and a heating device is installed at the bottom of the reactor; among them, the cutting coil and the speed control connected to the device. Turn on the tachometer 5 to control the coil cutting speed and stirring speed. The outlet of reaction kettle 1 is connected to the feed port of rectification tower 6 through pipelines, and the inlet on one side of rectification tower 6 is connected to reboiler 8; In the tower body, the low-boiling volatile fraction enters the condenser 7, and after the reflux is controlled by the reflux valve 9, the fraction flows out of the condenser.

[0022] Approach:

[0023] The COD of the disperse red dye wastewater to be treated is 17000mg / L, and the acetic acid content is about 1%....

Embodiment 2

[0028] The difference from Example 1 is:

[0029] Approach:

[0030] The COD of the disperse red dye wastewater to be treated is 17000mg / L, and the acetic acid content is about 1%.

[0031] The disperse red dye waste water and methanol to be treated are entered successively through the feed port of the rectification reactor, 1 kg of disperse red dye waste water, and 0.25 kg of methanol (analytical pure), in order to avoid the surfactant in the waste water from producing a large amount of foam during the rectification process , and then add 0.05 g of silicone defoamer. Turn on the electromagnetic equipment, the reflux temperature rises to 65°C, the magnetic field strength is 0.5T, and the temperature rises to reflux for magnetoelectric catalysis. The electric field generated inside the reactor can change the internal potential difference of the electrolyte to promote the esterification reaction. After 10 minutes of the esterification reaction, the Pressure (0~0.2MPa), when th...

Embodiment 3

[0034] The difference from Example 1 is:

[0035] Approach:

[0036]The COD of the disperse red dye wastewater to be treated is 17000mg / L, and the acetate content is 1%. The disperse red dye waste water and methanol to be treated are entered successively through the feed port of the rectification reactor, 1 kg of disperse red dye waste water, and 0.5 kg of methanol (analytical pure), in order to avoid the surfactant in the waste water from producing a large amount of foam during the rectification process , and then add 0.05 g of silicone defoamer. Turn on the electromagnetic equipment, the reflux temperature rises to 65°C, the magnetic field strength is 0.4T, and the temperature rises to reflux for magnetoelectric catalysis. The electric field generated inside the reactor can change the internal potential difference of the electrolyte to promote the esterification reaction. After 10 minutes of the esterification reaction, the Pressure (0~0.2MPa), when the temperature of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap