Low-cost gypsum-based self-leveling material

A gypsum-based, self-leveling technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low flexural strength and compressive strength of self-leveling materials, environmental pollution, and unfavorable environmental protection. Achieve the effect of alleviating the pressure on environmental resources, reducing carbon emissions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

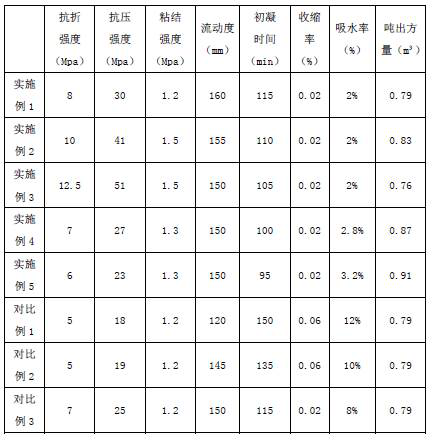

Examples

Embodiment 1

[0034] The low-cost gypsum-based self-leveling material in this example is prepared by mixing the following raw materials in parts by weight: 500 parts of desulfurized gypsum α gypsum powder, 500 parts of fly ash, 5 parts of ordinary Portland cement, and 1 part of polycarboxylate superplasticizer 0.3 part of silane defoamer, 0.4 part of sodium bentonite, 0.4 part of 400 hydroxypropyl methylcellulose, 2 parts of vinyl acetate and ethylene copolymer latex powder, 0.2 part of organosilane water-repellent agent, protein 0.3 parts of retarder.

[0035] The preparation method of desulfurized gypsum α gypsum powder in this embodiment comprises the following steps:

[0036](1) Mix the desulfurized gypsum raw material with the composite admixture evenly. The composite admixture is composed of calcium phosphate, aluminum sulfate and sodium citrate in a weight ratio of 15:45:2. The amount of the composite admixture is the weight of the desulfurized gypsum raw material 1.5% of the mixed ...

Embodiment 2

[0043] The low-cost gypsum-based self-leveling material in this example is prepared by mixing the following raw materials in parts by weight: 600 parts of desulfurized gypsum α gypsum powder, 400 parts of fly ash, 10 parts of ordinary portland cement, and 1 part of polycarboxylate superplasticizer 0.3 part of silane defoamer, 0.4 part of sodium bentonite, 0.4 part of 400 hydroxypropyl methylcellulose, 4 parts of vinyl acetate and ethylene copolymer latex powder, 0.2 part of organosilane water-repellent agent, protein 0.3 parts of retarder.

[0044] The water consumption of the low-cost gypsum-based self-leveling material in this embodiment is 0.35% of the total weight. After being stirred into a slurry, it is used for ground self-leveling construction.

Embodiment 3

[0046] The low-cost gypsum-based self-leveling material in this example is prepared by mixing the following raw materials in parts by weight: 700 parts of desulfurized gypsum α gypsum powder, 300 parts of fly ash, 10 parts of ordinary portland cement, and 1.5 parts of polycarboxylate superplasticizer 0.3 part of silane defoamer, 0.4 part of sodium bentonite, 0.4 part of 400 hydroxypropyl methylcellulose, 4 parts of vinyl acetate and ethylene copolymer latex powder, 0.2 part of organosilane water-repellent agent, protein 0.3 parts of retarder.

[0047] The low-cost gypsum-based self-leveling material in this embodiment uses 0.3% of the total weight of water when used, and after being stirred into a slurry, it is used for ground self-leveling construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com