Photothermal conversion film with heterostructure light trapping enhancement and preparation method of photothermal conversion film

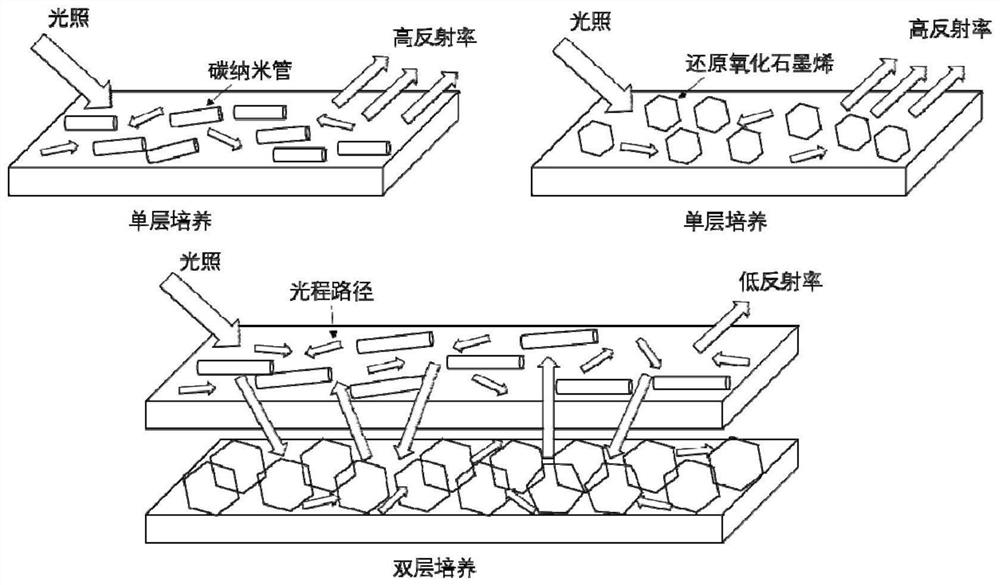

A heterogeneous structure, light-to-heat conversion technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, lighting and heating equipment, etc., can solve the problem of low evaporation rate of solar interface seawater evaporators, inability to meet small-scale portable needs, Problems such as light capture efficiency and light utilization rate are low, to achieve the effect of improving light absorption efficiency, easy mass production, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

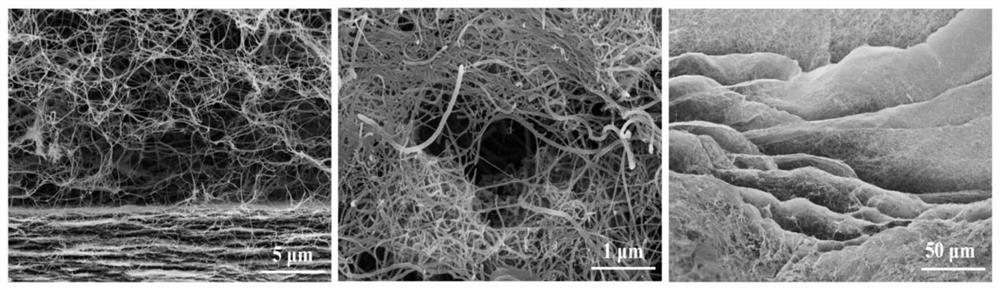

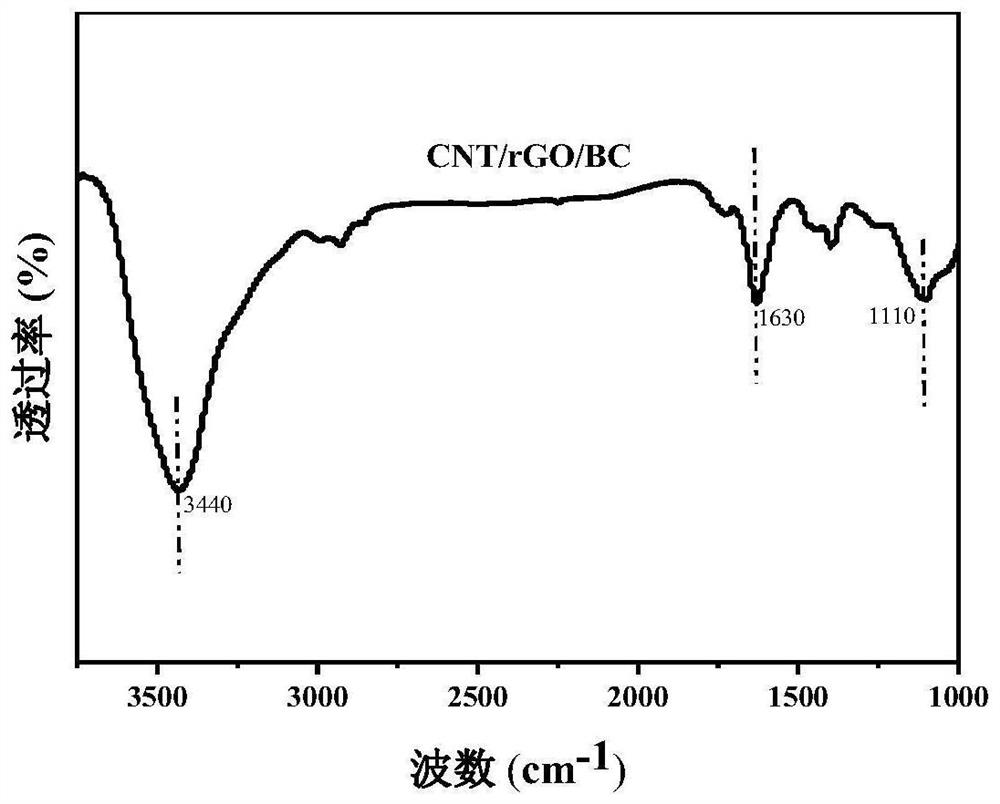

[0060] A method of preparing a photothermal conversion film having a heterogeneous structure traps, the specific steps are as follows:

[0061] (1) Preparation of CNT-BC hydrogel;

[0062] (1.1) formulated CNT water dispersion and HS nutrient solution, respectively;

[0063] The CNT water dispersion is obtained by adding CNT powder to ultrasonic dispersion evenly, the concentration of CNT water dispersion is 5 mg / ml;

[0064] HS nutrient solution from 40g / L glucose, 3g / L yeast extract, 3g / L protein, 1g / L NA 2 HPO 4 0.5g / lkh 2 PO 4 , 0.5 g / l of citric acid and margin ultrapure water composition; HS nutrient solution is: proportion of glucose, yeast extract, protein, NA 2 HPO 4 KH 2 PO 4 After stirring with citric acid, it was mixed with ultrapure water, and the high-pressure sterilizer was sterilized for 30 min with a high-pressure sterilizer at a temperature of 110 ° C and a pressure of 0.3 MPa, and a sterile cooled to 28 ° C to obtain an HS nutrient solution;

[006...

Embodiment 2

[0086] A method of preparing a photothermal conversion film having a heterogeneous structure traps, the specific steps are as follows:

[0087] (1) Preparation of CNT-BC hydrogel;

[0088] (1.1) formulated CNT water dispersion and HS nutrient solution, respectively;

[0089] The CNT aqueous dispersion is obtained by adding CNT powder to ultrasonic dispersion, and the concentration of CNT water dispersion is 5.5 mg / ml;

[0090] HS nutrient solution by 50 g / l glucose, 5g / L yeast extract, 5g / L protein, 2g / l NA 2 HPO 4 1g / lkh 2 PO 4 The ultrapure water of 1 g / L citric acid and margin; the formulation process of HS nutrient solution is: proportion of glucose, yeast extract, protein, NA 2 HPO 4 KH 2 PO 4 After adding ultrapure water, the mixture was mixed with citric acid, and the high-pressure sterilizer was sterilized with a high-pressure sterilizer at a temperature of 115 ° C and a pressure of 0.25 MPa, and a sterile cooled to 26 ° C to obtain an HS nutrient solution;

...

Embodiment 3

[0105] A method of preparing a photothermal conversion film having a heterogeneous structure traps, the specific steps are as follows:

[0106] (1) Preparation of CNT-BC hydrogel;

[0107] (1.1) formulated CNT water dispersion and HS nutrient solution, respectively;

[0108] CNT aqueous dispersion is obtained by CNT powder was added to deionized water to obtain a homogeneous ultrasonic dispersion, the concentration of CNT aqueous dispersion of 6mg / mL;

[0109] HS nutrient solution of 60g / L glucose, 8g / L yeast extract, 8g / L peptone, 4g / L Na 2 HPO 4 , 2g / LKH 2 PO 4 , Ultra-pure water 2g / L citric acid and the balance; HS nutrient solution preparation process is as follows: the proportion of glucose, yeast extract, peptone, Na 2 HPO 4 KH 2 PO 4 After the addition of citric acid and ultrapure water Stir it is at a temperature of 120 deg.] C and a pressure of 0.2MPa by autoclave sterilization temperature 40min, cooled to a sterile 24 ℃, to obtain HS nutrient solution;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com