Dedusting ash micronization recycling technological method

A process method, micronization technology, applied in the direction of process efficiency improvement, etc., can solve the problems of sintering production capacity decline, mixed material difficult to granulate, small particle size, etc., to achieve the improvement of machine speed and utilization factor, optimize the batching structure, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

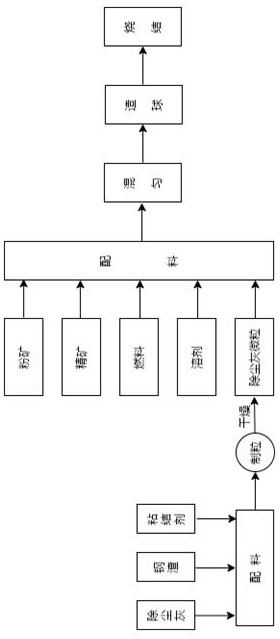

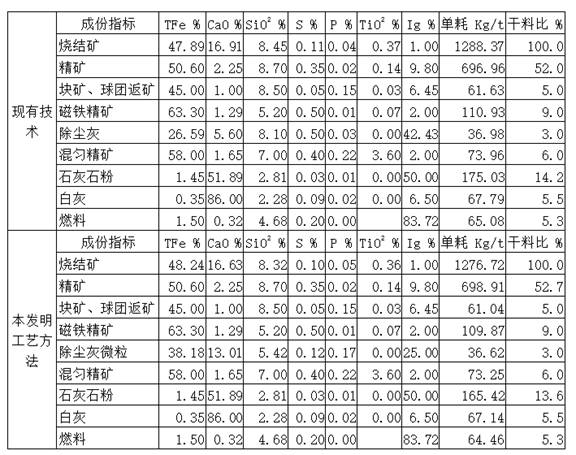

[0026] Such as figure 1 Shown, a kind of dedusting ash micronization recycling process method of the present invention comprises the following steps:

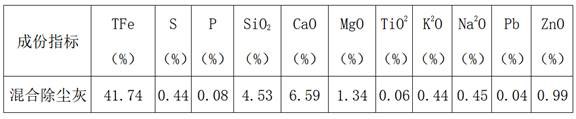

[0027] S1. Iron-containing dust is mixed and pretreated to form mixed dust, which includes sintering dust, blast furnace gas ash, casthouse dust, converter mud and gas mud, sintering dust, blast furnace gas The mass proportion of iron yard dust, converter mud and gas mud is 3:3:2:1:1;

[0028] S2. adding steel slag particles and limestone powder to the mixed dedusting ash prepared in step S1 as a binder, wherein the mass ratio of limestone powder is 2%-3.5%, and wherein the mass ratio of steel slag particles is less than or equal to 8%;

[0029] S3. adding water with a mass ratio of 6%-8% to the mixture that has completed step S2 for wetting, and after wetting, carry out micronization treatment through a disc pelletizer to form dust particles with a diameter of 2mm-6mm;

[0030] S4. Perform drying treatment on the dedusted as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com