Prussian blue derived core-shell cubic material as well as preparation method and application thereof

A technology of Prussian blue and cubes, applied in nanotechnology for materials and surface science, carbon preparation/purification, final product manufacturing, etc., can solve the problem of reducing electrode material cycle life and rate performance, active material loss, material structure Problems such as pulverization, to achieve the effect of enhancing cycle stability and reversible specific capacity, improving stability, and improving reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the Prussian blue compound comprises: dissolving polyvinylpyrrolidone (PVP) and potassium ferricyanide in dilute hydrochloric acid, and aging treatment; or, the mass ratio of PVP and potassium ferricyanide is 6-24:1 .

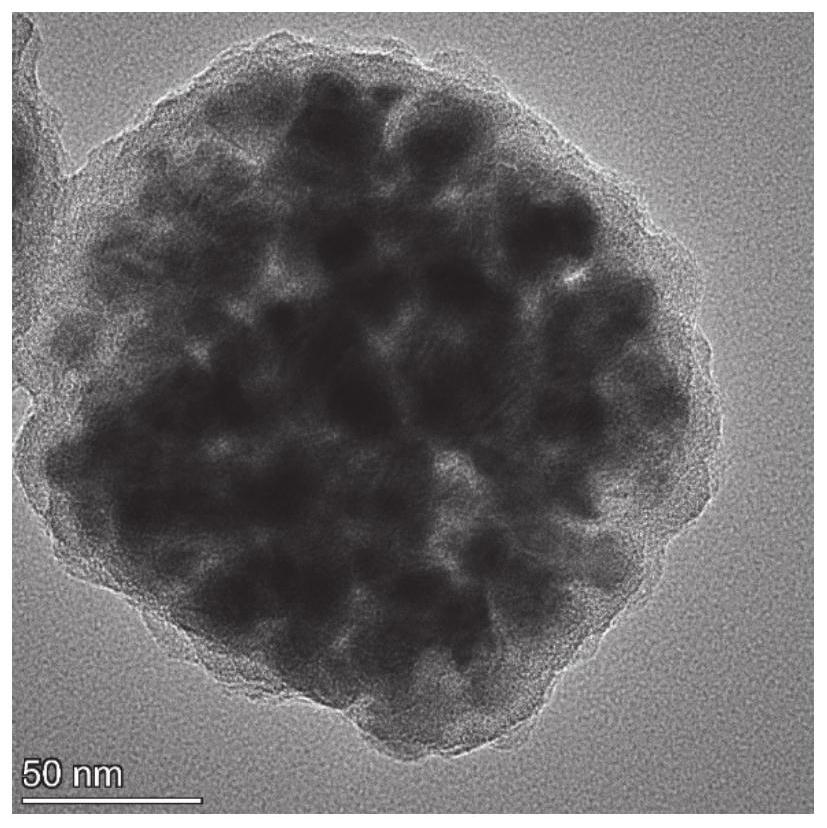

[0031] The polymerization reaction is a reaction for preparing phenolic resin; further, the raw materials for preparing phenolic resin are resorcinol and formaldehyde. The use of phenolic resin is more conducive to enhancing the structural stability of the electrode material during the calcination process, increasing the network dimension, and obtaining a three-dimensional network structure with a complete core-shell cubic structure. At the same time, it is beneficial to alleviate the volume expansion effect of the cubic electrode material during battery charging and discharging, and enhance structural stability. for better electrochemical performance.

[0032]Specifically, the preparation process of the phenolic resin is obtai...

Embodiment 1

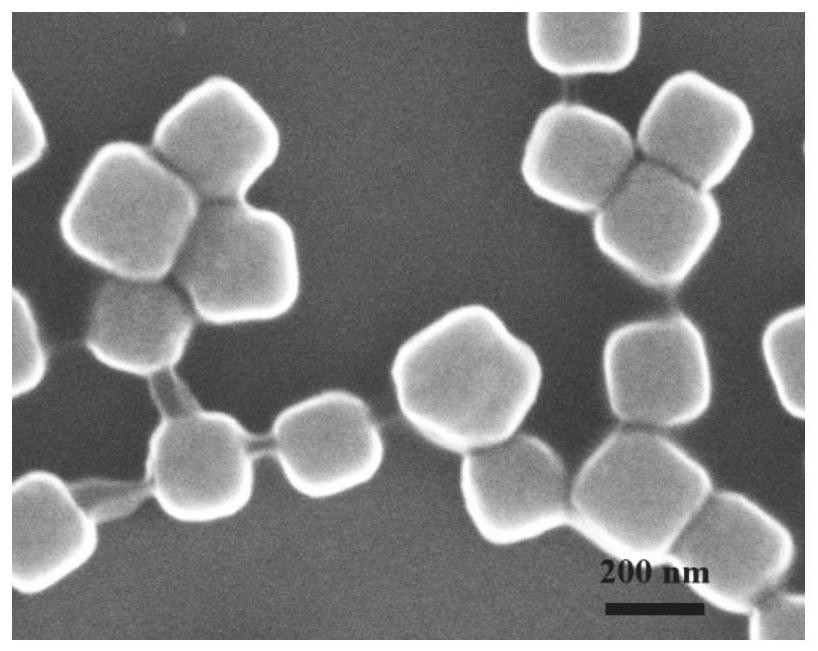

[0041] Prussian Blue Derived 3D Network Fe 7 Se 8 - Preparation method of C@C core-shell cubic electrode material:

[0042] (1) Dissolve polyvinylpyrrolidone (PVP, K-30, MW=40000) and potassium ferricyanide with a mass ratio of 24:1 in 300ml of 0.1mol / L dilute hydrochloric acid solution, and age in an oven at 80°C After 24 hours of treatment, a Prussian blue (PB) solution was obtained. The precipitate was washed by centrifugation with ethanol and deionized water, dried in vacuo, and the solid was collected to obtain a precipitate of Prussian blue PB.

[0043] (2) Pour 0.1g of PB into a mixed solution of deionized water and absolute ethanol with a volume ratio of 7:3, stir with magnetic force for 30min, and then add CTAB and resorcinol with a mass ratio of 6:1, and The volume ratio is 1:6 ammonia water (concentration: 26.0wt.%) and formaldehyde solution, react for 8h. The precipitate was washed by centrifugation with ethanol and deionized water, and vacuum-dried to obtain a...

Embodiment 2

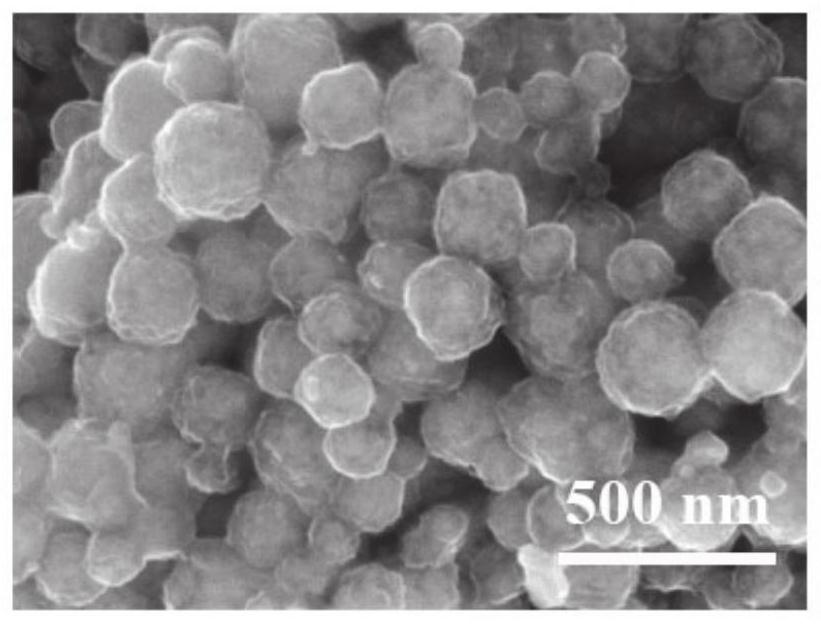

[0052] Prussian Blue Derived 3D Network Fe 7 Se 8 - Preparation method of C@C core-shell cubic electrode material:

[0053] (1) Dissolve polyvinylpyrrolidone (PVP, K-30, MW=40000) and potassium ferricyanide with a mass ratio of 18:1 in 300ml of 0.1mol / L dilute hydrochloric acid solution, and age in an oven at 80°C After 24 hours of treatment, a Prussian blue (PB) solution was obtained. The precipitate was washed by centrifugation with ethanol and deionized water, dried in vacuo, and the solid was collected to obtain a precipitate of Prussian blue PB.

[0054] (2) Pour 0.1g of PB into a mixed solution of deionized water and absolute ethanol with a volume ratio of 7:4, magnetically stir and stir for 30min, and then add CTAB and resorcinol with a mass ratio of 3:1, and The volume ratio is 1:5 ammonia water (concentration: 26.0wt.%) and formaldehyde solution, react for 6h. The precipitate was washed by centrifugation with ethanol and deionized water, and dried in vacuum to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com