High-adenosine and high-ergosterol fermented cordyceps sinensis powder and production method thereof

A technology of high-adenosine high-ergosterol, fermented Cordyceps fungus powder, applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, plant/algae/fungus/moss components, etc., can solve the overall level of adenosine and ergosterol content Large fluctuations, high production costs, few deviation adjustment methods, etc., to achieve the effect of improving production efficiency and equipment utilization, quality stability, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

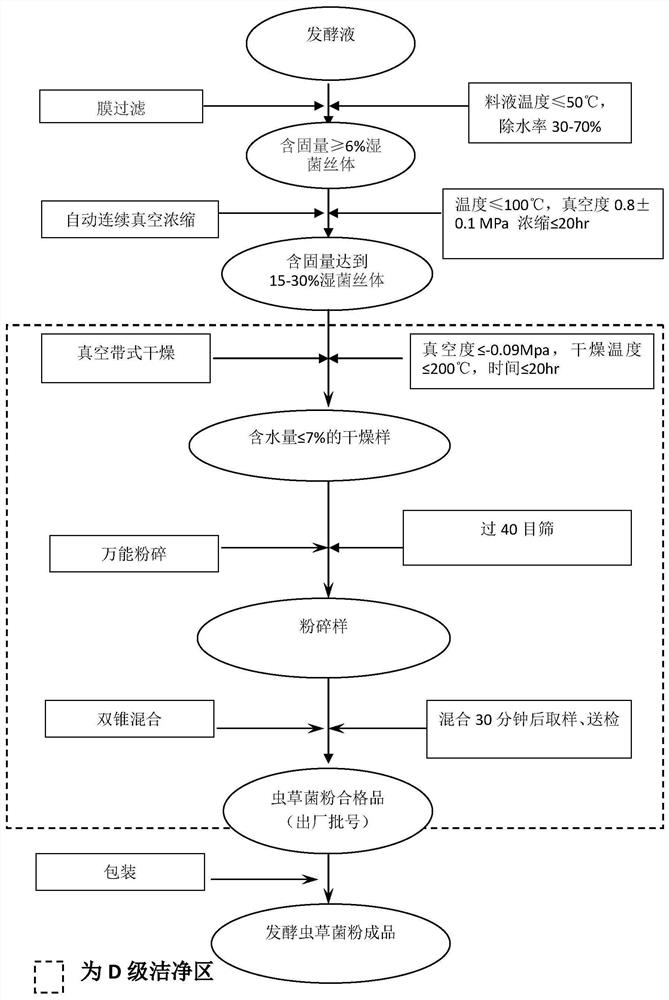

Method used

Image

Examples

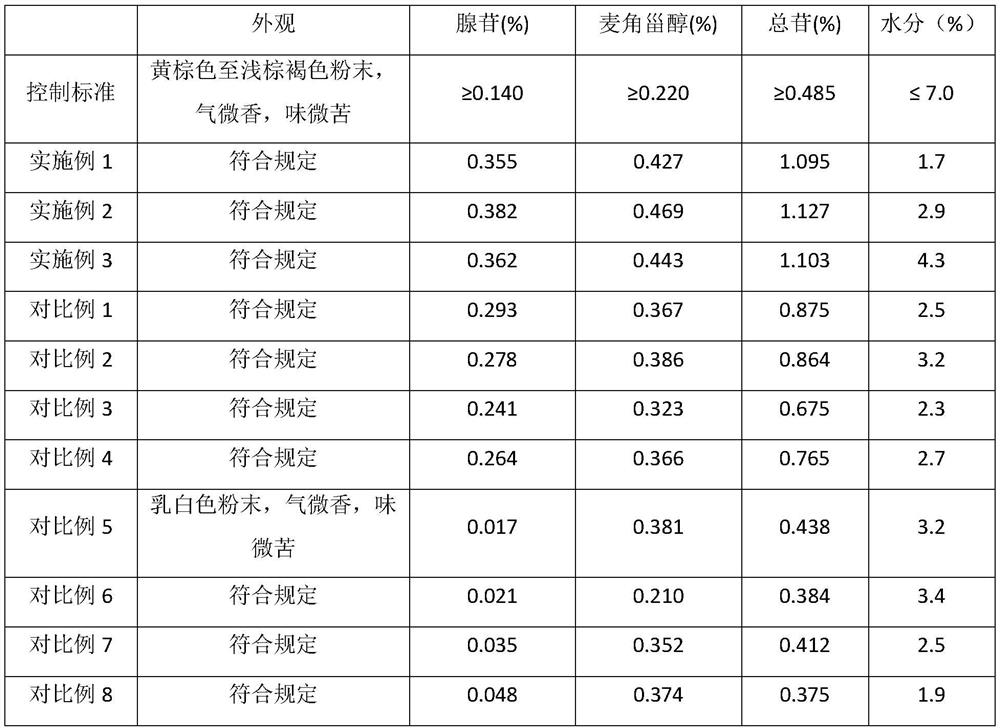

Embodiment 1

[0047] S1. Start the feeding pump, put 30 tons of bacteria with an age of 55h, a bacterial concentration of 24ml / 100ml, a solid content of 4.59%, a PH of 4.13, a well-differentiated primordium, a whitish material color, and no bacterial contamination. The standard cordyceps fermentation liquid is pumped into the raw material storage tank for storage, and the sterile air is introduced to control the tank pressure of 0.02MPa, cooled with a water jacket at 9°C, and the material temperature is kept at 30°C, and the storage time is 15h. Start the feeding pump, pump the Cordyceps fermented liquid into the ceramic membrane filter with a membrane aperture of 100nm, control the inlet pressure to be 0.4±0.05MPa, the medium pressure to 0.3±0.05MPa, the outlet pressure to be 0.15±0.05MPa, and the temperature to be 50℃ , pH after membrane: 4.89, mycelium and filtrate were separated, 31.2% of mother liquor was removed, and a concentrated solution of Cordyceps ceramic membrane with a solid co...

Embodiment 2

[0052] S1. Start the feeding pump, put 30 tons of bacteria with an age of 65h, a bacterial concentration of 28ml / 100ml, a solid content of 3.97%, a pH of 5.29, a well-differentiated primordium, a whitish material color, and no bacterial contamination. The cordyceps fermented liquid that reaches the standard of storage is pumped into the raw material storage tank for storage, and the sterile air is introduced into the control tank to control the pressure of 0.04Mpa, and the water jacket is cooled at 9°C. Start the feed pump to pump the Cordyceps fermentation broth into the TiO with a membrane pore size of 200nm 2 In the metal oxide membrane filter, the inlet pressure is controlled to be 0.4±0.05Mpa, the medium pressure is 0.3±0.05Mpa, the outlet pressure is 0.15±0.05Mpa, the temperature is 40°C, the pH after the membrane is 5.62, and the mycelium is separated from the filtrate. Remove 52.4% of the mother liquor to obtain Cordyceps TiO with a solid content of 8.13% 2 Metal oxid...

Embodiment 3

[0057] S1. Start the feeding pump, put 30 tons of bacteria with age 75h, bacteria concentration of 32ml / 100ml, solid content: 3.10%, PH: 5.65, good primordial differentiation, white color, and no bacterial contamination. The cordyceps fermented liquid that has reached the standard of storage is pumped into the raw material storage tank for storage, and the sterile air is introduced into the control tank to control the pressure of 0.05Mpa. Start the feeding pump, pump the Cordyceps fermented liquid into the polyfluoropolymer organic membrane filter with a membrane aperture of 600nm, control the inlet pressure: 0.4±0.05Mpa, the middle pressure: 0.3±0.05Mpa, and the outlet pressure: 0.15±0.05Mpa , the temperature is 30℃, the pH after the membrane is 5.93, and the mycelium is separated from the filtrate. 68.5% of the mother liquor was removed to obtain a concentrated solution of Cordyceps polyfluoropolymer organic membrane with a solid content of 9.36%.

[0058] S2. Start the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com