Plating solution for chemical nickel plating on surface of neodymium-iron-boron magnetic material and plating method of plating layer

A surface chemistry, NdFeB technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of hydrogen evolution and magnetic performance decline of NdFeB magnetic materials, so as to improve anti-corrosion performance and guarantee The effect of stability, huge market application prospect and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

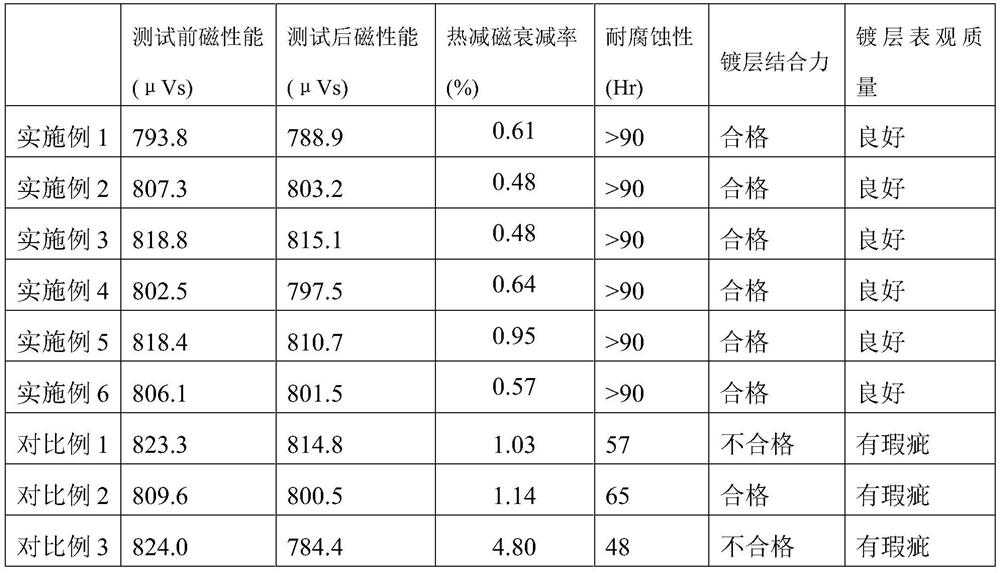

Examples

Embodiment 1

[0046] This embodiment is used for the plating solution of electroless nickel plating on the surface of NdFeB magnetic material, the solvent of described plating solution is deionized water, and the mass concentration range of each component in described plating solution is: 50g / L nickel acetate, 220g / L complexing agent, 55g / L glycine, 140g / L hydrazine and 2.2g / L stabilizer, and the pH value of the plating solution is 12.

[0047] The complexing agent is composed of ethanolamine and glycolic acid with a mass ratio of 30:1;

[0048] The stabilizer is compounded by stabilizer A, stabilizer B and stabilizer C with a mass ratio of 1:100:4.

[0049] The stabilizer A is lead acetate, the stabilizer B is composed of ethoxy propynol ether and sulfuric acid with a mass ratio of 50:1, and the stabilizer C is composed of potassium iodate and potassium hydroxide with a mass ratio of 3:1.

[0050] A method for coating the surface of an NdFeB magnetic material, the method for coating the ...

Embodiment 2

[0062] This embodiment is used for the plating solution of electroless nickel plating on the surface of NdFeB magnetic material, the solvent of described plating solution is deionized water, and the mass concentration range of each component in described plating solution is: 30g / L nickel acetate, 160g / L complexing agent, 30g / L glycine, 130g / L hydrazine and 1g / L stabilizer, and the pH value of the plating solution is 11.

[0063] The complexing agent is composed of diethanolamine and sodium citrate with a mass ratio of 10:1;

[0064] The stabilizer is compounded by stabilizer A, stabilizer B and stabilizer C with a mass ratio of 0.8:80:3.2.

[0065] The stabilizer A is lead acetate, the stabilizer B is composed of ethoxy propynol ether and sulfuric acid with a mass ratio of 40:1, and the stabilizer C is composed of potassium iodate and potassium hydroxide with a mass ratio of 2.4:1.

[0066] A method for coating the surface of an NdFeB magnetic material, the method for coatin...

Embodiment 3

[0078] This embodiment is used for the plating solution of electroless nickel plating on the surface of NdFeB magnetic material, the solvent of described plating solution is deionized water, and the mass concentration range of each component in described plating solution is: 80g / L nickel acetate, 280g / L complexing agent, 80g / L glycolic acid, 150g / L hydrazine and 3.5g / L stabilizer, and the pH value of the plating solution is 13.

[0079] The complexing agent is composed of triethanolamine and ethylenediaminetetraacetic acid with a mass ratio of 50:1;

[0080] The stabilizer is compounded by stabilizer A, stabilizer B and stabilizer C with a mass ratio of 1.2:120:4.8.

[0081] The stabilizer A is lead acetate, the stabilizer B is composed of ethoxy propynol ether and sulfuric acid with a mass ratio of 70:1, and the stabilizer C is composed of potassium iodate and potassium hydroxide with a mass ratio of 3.6:1.

[0082] A method for coating the surface of an NdFeB magnetic mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com