Method for laser cladding of high-entropy alloy coating on copper surface

A high-entropy alloy and laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problem of insufficient surface strengthening performance of pure copper, and achieve the effect of high strength, hardness and strength improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Laser cladding AlMoTiMnCr on a copper surface x Zr y A method for coating a high-entropy alloy comprising the steps of:

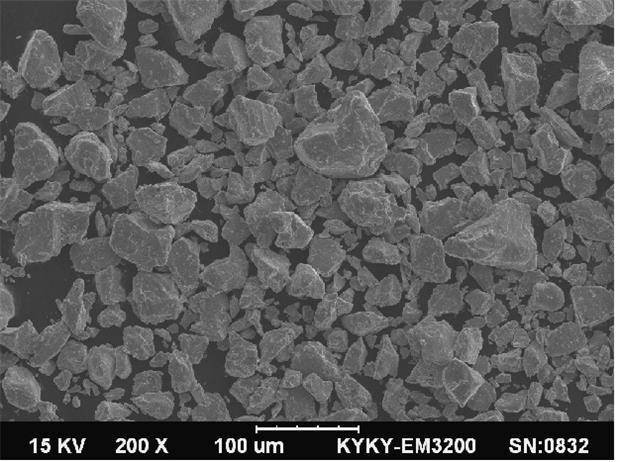

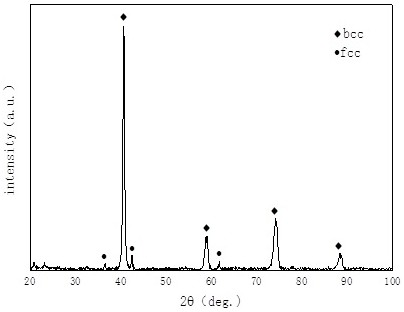

[0033] (1) AlMoTiMnCr x Zr y Preparation of high entropy alloy powder:

[0034] Pre-cut Al, Mo, Ti, Mn, Cr, Zr metal blocks into small pieces, use sandpaper to remove the oxide layer on the surface of the material, wipe it clean with anhydrous ethanol, and use an electronic balance to weigh the ratio in equal proportions. Al, Mo, Ti, Mn, Cr and Zr have the same mole fraction (x=1, y=1). Vacuum arc melting equipment is used to repeatedly smelt metal blocks to make the composition of alloy ingots uniform. The resulting smelted balls were crushed and pulverized with a vibration mill for 30 seconds. The particles are sieved through a 200-mesh sieve to obtain AlMoTiMnCrZr high-entropy alloy powder with a particle size smaller than 74 μm.

[0035] (2) Surface pretreatment of pure copper substrate:

[0036] Pure copper is selected as the substrate, ...

Embodiment 2

[0046] Laser cladding AlMoTiMnCr on a copper surface x Zr y A method for coating a high-entropy alloy comprising the steps of:

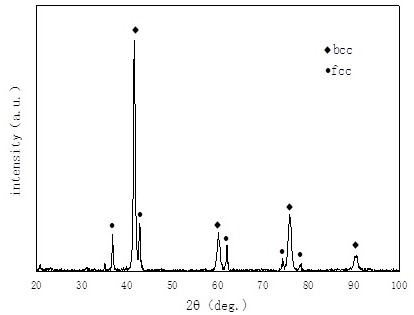

[0047] (1) AlMoTiMnCr x Zr y Preparation of high entropy alloy powder:

[0048] Pre-cut the metal blocks of Al, Mo, Ti, Mn, Cr, and Zr into small pieces, use sandpaper to remove the oxide layer on the surface of the material, wipe it clean with absolute ethanol, and use an electronic balance to weigh the ratio in equal proportions. , Mo, Ti, Mn and Cr have the same mole fraction, and the Zr content is 0 (x=1, y=0). Vacuum arc melting equipment is used to repeatedly smelt metal blocks to make the composition of alloy ingots uniform. The obtained smelting balls were crushed, crushed with a vibrating mill for 30 seconds, and sieved through a 200-mesh sieve to obtain AlMoTiMnCr high-entropy alloy powder with a particle size of less than 74 μm.

[0049] (2) Surface pretreatment of pure copper substrate:

[0050] Pure copper is selected as the substra...

Embodiment 3

[0059] Laser cladding AlMoTiMnCr on a copper surface x Zr y A method for coating a high-entropy alloy comprising the steps of:

[0060] (1) AlMoTiMnCr x Zr y Preparation of high entropy alloy powder:

[0061] Cut each metal block of Al, Mo, Ti, Mn, Cr, and Zr into small pieces in advance, use sandpaper to remove the oxide layer on the surface of the material, wipe it clean with absolute ethanol, and use an electronic balance to weigh the ratio of Al, Mo, Ti, Mn and Zr have the same mole fraction, and the Cr content is 0 (x=0, y=1). Vacuum arc melting equipment is used to repeatedly smelt metal blocks to make the composition of alloy ingots uniform. The obtained smelting balls were crushed, crushed with a vibrating mill for 30 seconds, and sieved with a 200-mesh sieve to obtain AlMoTiMnZr high-entropy alloy powder with a particle size smaller than 74 μm.

[0062] (2) Surface pretreatment of pure copper substrate:

[0063] Pure copper is selected as the substrate, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com