Tunable mode converter and preparation method thereof

A mode converter and device technology, applied in the direction of optical waveguide light guide, optics, light guide, etc., can solve the problems of small number of modes, limited optical communication data transmission capacity, and device inability to tune, and achieve low production cost, strong interference effect, The effect of large thermo-optic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

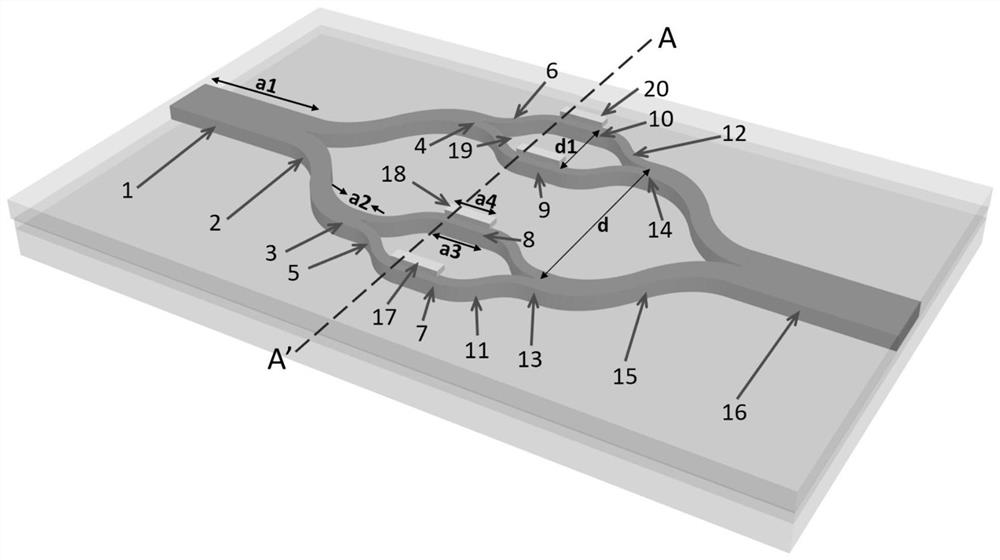

[0071] The present invention will be further described below in conjunction with drawings and embodiments.

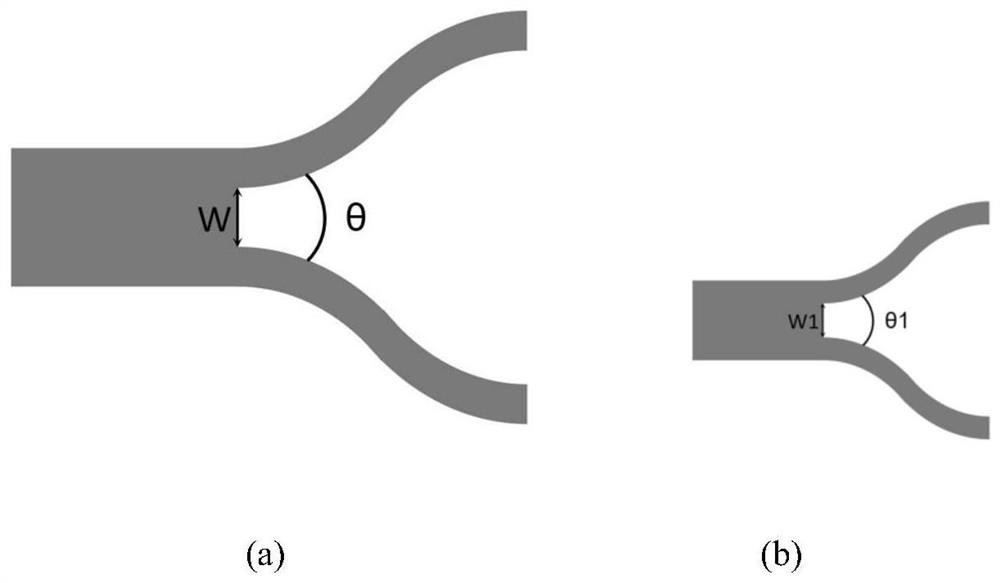

[0072] Example structure such as figure 1 As shown, the lengths a1 and a1' of the input few-mode straight waveguide 1 and the output few-mode straight waveguide 16 are equal to 1 cm, the first input straight waveguide 3, the second input straight waveguide 4, the first output straight waveguide 13, the second output straight waveguide The lengths a2, a2', a2", a2"' of the straight waveguide 14 are equal to 500 μm. The lengths a3, a3', a3", a3"' of the first modulation arm 7, the second modulation arm 8, the third modulation arm 9 and the fourth modulation arm 10 are equal to 0.3cm, and the two parallel MZI optical waveguide structures The center distance d between the interference arms is 104 μm, the center distance d1 between the two parallel interference arms of the secondary MZI optical waveguide structure is equal to 52 μm, the first heating electrode 17, the secon...

Embodiment 2

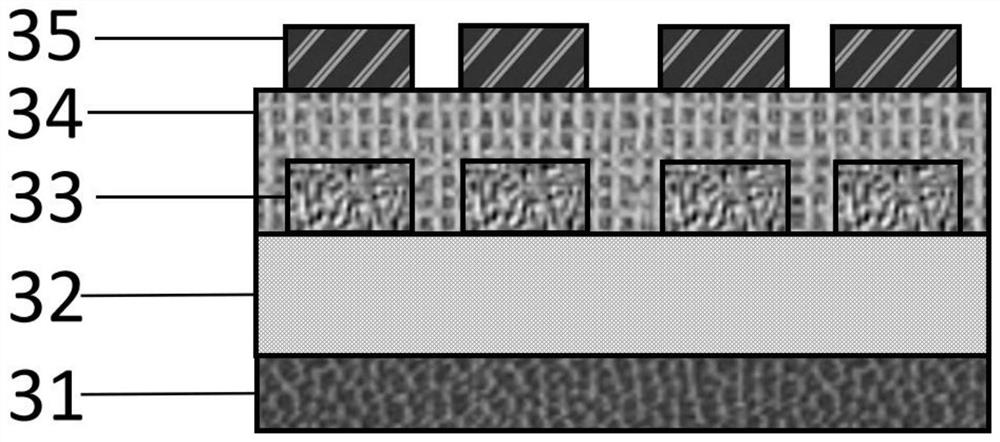

[0094] Cleaning of the silicon wafer substrate: Wipe the silicon wafer substrate repeatedly with a cotton ball dipped in acetone, then repeatedly wipe the silicon wafer substrate with a cotton ball dipped in ethanol, then rinse it with deionized water, and dry it with nitrogen Place into a clean Petri dish and seal.

[0095] Preparing the lower cladding layer 32 of silicon dioxide by thermal oxidation: growing a lower cladding layer of silicon dioxide with a thickness of 15 μm by thermal oxidation.

[0096] The optical waveguide core layer 33 of the device including the input / output region, Y branch beam splitter / coupler and modulation arm is prepared by spin coating, photolithography, and wet etching processes: the spin coating process will have a negative thermo-optic coefficient The polymer material SU-82002 is spin-coated on the clean silicon dioxide lower cladding layer at a speed of 2500 rpm, and the silicon wafer spin-coated with the polymer film is pre-baked, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com