Dehydration crystallization method of vinylene carbonate

A vinylene carbonate and water agent technology, applied in the direction of organic chemistry, etc., can solve the problems of unfavorable enterprises in energy saving and emission reduction, easy polymerization and coking, and high water residue, and achieves the advantages of avoiding polymerization and coking, good repeatability and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

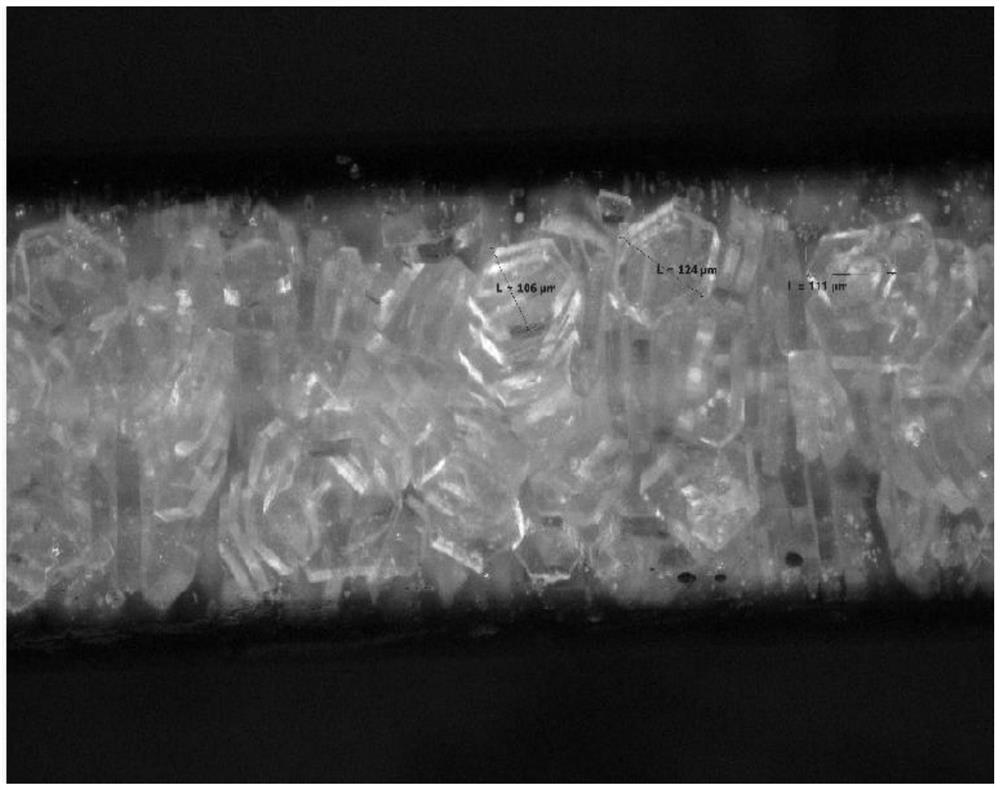

Image

Examples

Embodiment 1

[0022] In a 200L reactor, add 180kg of crude vinylene carbonate with a purity of 95%, and then add activated Molecular sieve 36kg was soaked to remove water, and the Karl Fischer water measurement method was used for online monitoring and water content measurement. When the water content is less than or equal to 50ppm, the vinylene carbonate is sent to a centrifuge for centrifugation, and the obtained centrifuged liquid is sent to a filter for filtration. The obtained clear liquid is sent to the temperature-controllable crystallization tank. Start the stirring system, the stirring rate is 250rpm, the temperature control system is set to drop from the initial 30°C to the end point 12°C, and the temperature drop time is set to 4 hours. After the crystallization process is completed, the crystals are transported to a three-in-one filter (filtering, washing, air blowing) for filtration treatment at 15°C, and the filtration accuracy is 300 mesh. The obtained crystals are blown...

Embodiment 2

[0024] The operation of this embodiment is basically the same as that of Embodiment 1, the difference is that the solid dewatering agent of this embodiment is Molecular sieve. Present embodiment obtains product and finally weighs 154kg. Yield: 85.6%. The liquid was taken for analysis, and the GC-MS purity was 99.73%. Trace detection results: ICP-OES (ppm): Na + =7.363ppm, Fe 2+ = 0.189ppm, Ca 2+ = 2.629ppm; Mg 2+ = 0.018ppm; IC: Cl - =14.91ppm, NO 3 - =3.28ppm, SO 4 2- =6.19ppm, PO 4 3- = 0.87ppm. KF: H 2 O=5.92ppm.

Embodiment 3

[0026] In a 200L reactor, add 150kg of vinylene carbonate crude product, then add 15kg of calcium hydride to carry out stirring reaction to remove water, and the stirring speed of the stirring blade is set to 350rpm. The Karl Fischer water measurement method is used for online monitoring and water content measurement. When the water content is less than or equal to 50ppm, stop stirring, let stand for 2 hours and wait for the solid-liquid layering, then transport the supernatant vinylene carbonate to a centrifuge for centrifugation, and then transport the obtained centrifuged liquid to a filter for filtration. The obtained clear liquid is sent to the temperature-controllable crystallization tank. Start the stirring system, the stirring rate is 250rpm, the temperature control system is set to drop from the initial 30°C to the end point 10°C, and the temperature drop time is set to 6 hours. After the crystallization process is completed, the crystals are transported to a three-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com