Hybrid emulsion, water-based inorganic coating prepared from hybrid emulsion and preparation methods of hybrid emulsion and water-based inorganic coating

A water-based inorganic coating and emulsion technology, applied in the direction of coating, etc., can solve the problems of cracks, micropores, scrub resistance, and poor water resistance of the paint film, and achieve excellent scrub resistance, easy promotion, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

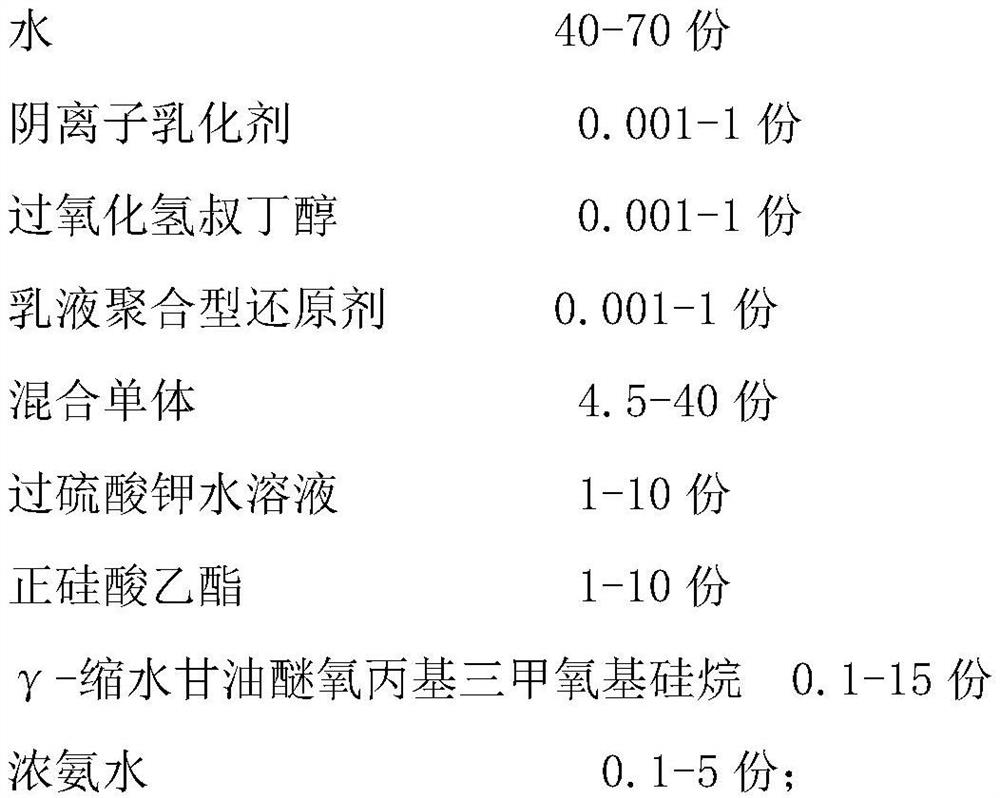

[0047] A hybrid emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0048]

[0049]

[0050] Wherein, the mixed monomer is mainly prepared from the following components according to the following ratios by weight:

[0051]

[0052] The weight percent of potassium persulfate in the potassium persulfate aqueous solution is 0.8%.

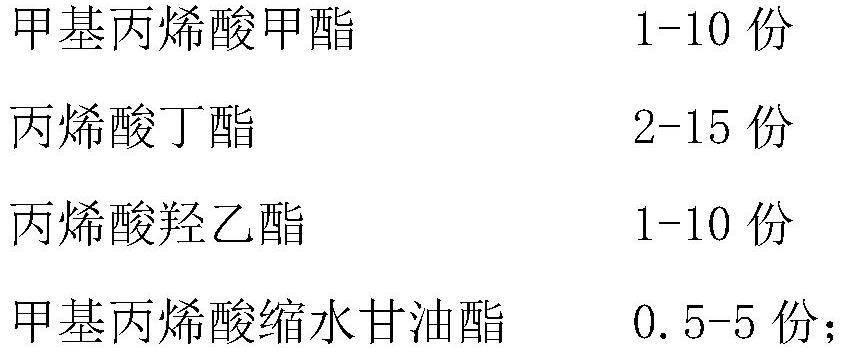

[0053] A water-based inorganic coating prepared from the hybrid emulsion is mainly prepared from the following components according to the following ratios by weight and number:

[0054]

[0055] Described thickening agent is hydroxyethyl cellulose.

[0056] The water-based dispersant is polyacrylic acid sodium salt dispersant.

[0057] The water-based wetting agent is secondary alcohol ethoxylate.

[0058] Described water-based defoamer is nonionic mineral oil.

[0059] The film-forming aid is 2,2,4-trimethyl-1,3-pentanediol isobutyrate die...

Embodiment 2

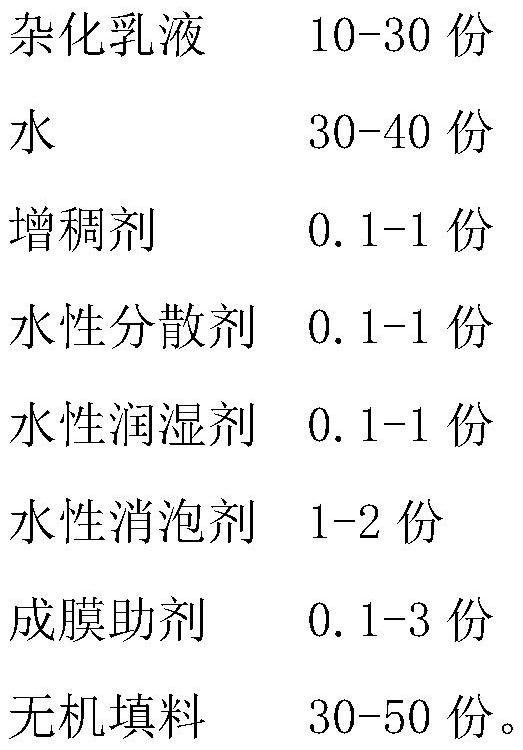

[0070] A hybrid emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0071]

[0072] Wherein, the mixed monomer is mainly prepared from the following components according to the following ratios by weight:

[0073]

[0074] The weight percent of potassium persulfate in the potassium persulfate aqueous solution is 0.9%.

[0075] A water-based inorganic coating prepared from the hybrid emulsion is mainly prepared from the following components according to the following ratios by weight and number:

[0076]

[0077]

[0078] Described thickening agent is hydroxyethyl cellulose.

[0079] The water-based dispersant is polyacrylic acid sodium salt dispersant.

[0080] The water-based wetting agent is a block copolymer.

[0081] Described water-based defoamer is nonionic mineral oil.

[0082] The film-forming aid is 2,2,4-trimethyl-1,3-pentanediol isobutyrate diester.

...

Embodiment 3

[0093] A hybrid emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0094]

[0095]

[0096] Wherein, the mixed monomer is mainly prepared from the following components according to the following ratios by weight:

[0097]

[0098] The weight percent of potassium persulfate in the potassium persulfate aqueous solution is 0.7%.

[0099] A water-based inorganic coating prepared from the hybrid emulsion is mainly prepared from the following components according to the following ratios by weight and number:

[0100]

[0101] Described thickening agent is hydroxyethyl cellulose.

[0102] The water-based dispersant is polyacrylic acid sodium salt dispersant.

[0103] The water-based wetting agent is any combination of secondary alcohol ethoxylate, block copolymer and alkyl polyoxyethylene ether.

[0104] Described water-based defoamer is nonionic mineral oil.

[0105] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com