Production method of rice-flavor liquor

A production method and a rice-flavored technology, applied in the field of winemaking, can solve the problems of low utilization rate of raw materials, low degree of mechanization, and easy occurrence of bitterness and astringency, and achieve the effects of low cost, good harmony, and mellow, sweet and soft taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

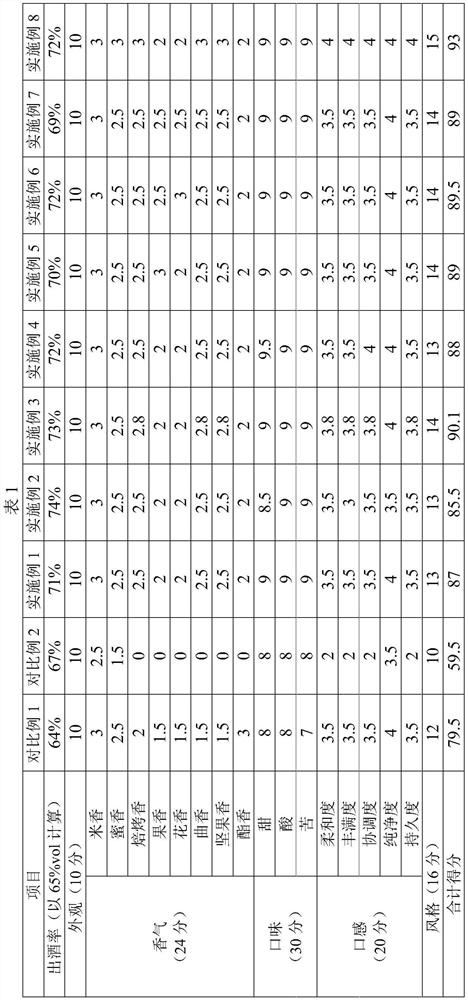

Examples

Embodiment 1

[0034] A production method of rice-flavored liquor, comprising the following steps:

[0035] (1) preparing rice koji, comprising the following steps:

[0036] A, Aspergillus oryzae (GIM3.29) was inoculated on the sterilized potato culture medium, cultivated for 5 days at 35°C;

[0037] B. Cook the japonica rice, inoculate the mold spores obtained in step A under aseptic conditions, fully break up and shake well, transfer to a 35-38°C incubator to cultivate for 4-5 days, and dry at 40°C to obtain a first-grade seed koji;

[0038] C, the japonica rice is boiled, and after cooling, insert the first-grade koji, the inoculum amount is 1.5%, stir evenly, 18~24h after starting to cultivate, the temperature is 34~37°C, and the humidity is 91%~95%. After culturing for 18-24 hours, the humidity is 75%-85%, and the temperature is 35-37°C. After culturing for 40-48 hours, the humidity is 55%-65%, and the temperature is 37-38°C. After culturing for 72 hours, drying is carried out at a d...

Embodiment 2

[0046] A kind of rice flavor liquor, its fermentation step is as follows:

[0047] 10 tons of japonica rice, 1800 kg of rice koji, 100 kg of cake balls, 5 kg of active dry yeast for Angel wine (Anqi Saccharomyces cerevisiae), and 18 tons of water. The temperature of the fermentation control product is 28-36°C, controlled and recorded every 2 hours, and the temperature is controlled for 96 hours. A total of 20 days of fermentation.

[0048] All the other steps are the same as in Example 1.

Embodiment 3

[0050] A kind of rice flavor liquor, its fermentation step is as follows:

[0051] 7 tons of indica rice, 3000 kg of rice koji, 200 kg of cake balls, 2 kg of Danbaoli Baijiu active dry yeast, and 18 tons of water. The temperature of the fermentation control product is 28-36°C, controlled and recorded every 2 hours, and the temperature is controlled for 96 hours. A total of 25 days of fermentation.

[0052] The used koji species of making rice koji is Rhizopus (CGMCC No.8589), and all the other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com