Food-grade safe saccharomycetes for producing chondroitin sulfate lyase ABCI and application of food-grade safe saccharomycetes

A technology of chondroitin sulfate and lyase, which is applied in the field of bioengineering and can solve the problems of limited application and the safety of chondroitin sulfate cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Construction of secreted and expressed recombinant Pichia pastoris GS115 / GAPZαB-ABCI

[0034]According to the chondroitin sulfate lyase derived from Proteus vulgaris, the coding gene ABCI was optimized through yeast codon preference to obtain the codon sequence shown in SEQ ID NO.1. The codon-optimized ABCI sequence was amplified with primers ABCI-F / R, and the vector GAPZαB was digested with EcoRI / KpnI, the amplified ABCI fragment and the digested vector were recovered separately, and obtained by one-step cloning Recombinant plasmid / GAPZαB-ABCI. The plasmid was linearized with fast cutting enzyme AvrII and then transformed into Pichia pastoris GS115 to obtain recombinant strain GS115 / GAPZαB-ABCI.

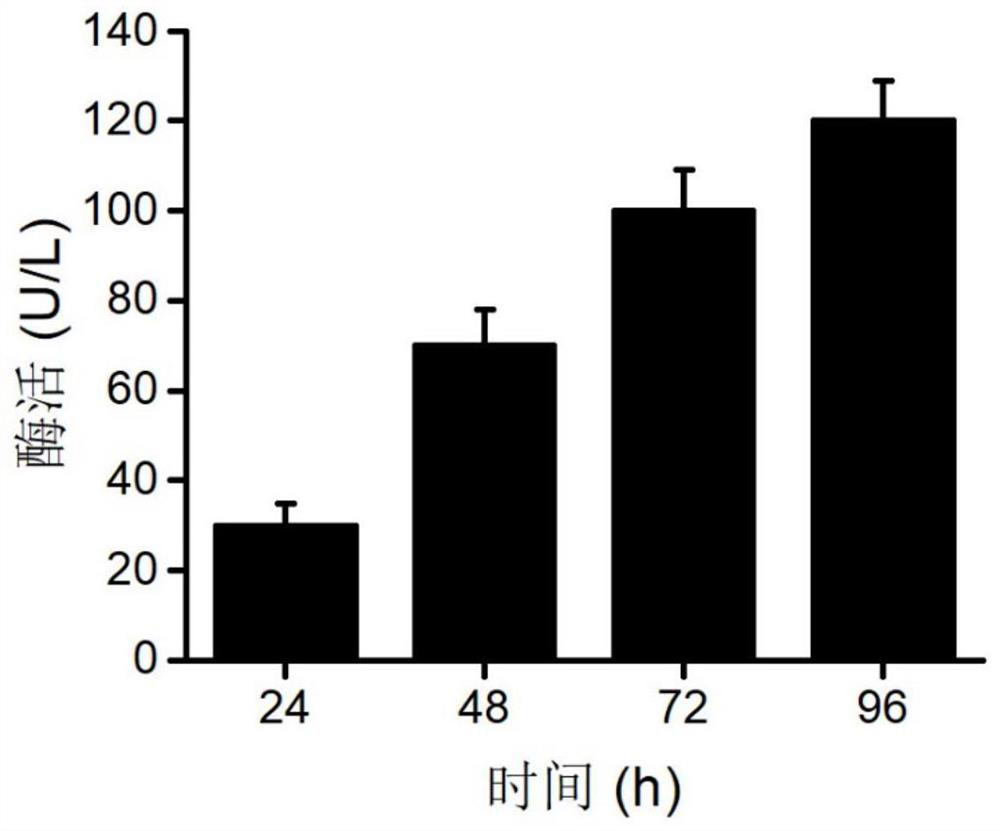

[0035] Streak the recombinant strain on the plate, pick a single colony and inoculate it in 5mL YPD liquid medium, cultivate it at 30°C and 220rpm for 16h, then transfer it to 50mL YPD medium according to 10% (v / v) inoculation amount, and place it in 30 Cultivate...

Embodiment 2

[0036] Example 2: P GAP Promoter mutations increase the expression of ABCI

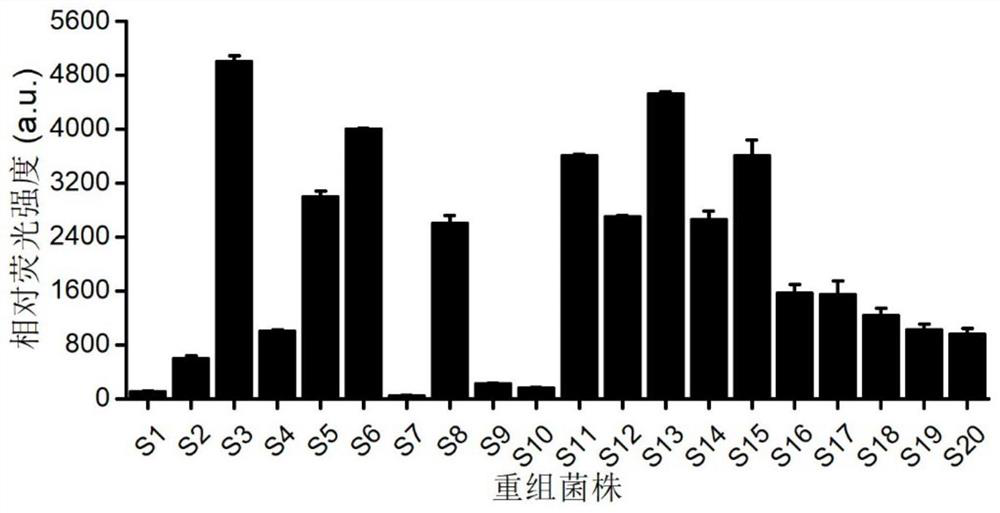

[0037] Since the initial secreted expression of ABCI was not high, the expression of the protein was further improved through promoter engineering. In order to facilitate the screening, ABCI needs to be expressed intracellularly, and at the same time, the fluorescent protein eGFP is connected after the ABCI gene, and the expression level of the protein is indicated by the intensity of fluorescence.

[0038] Use primer 2ABCI-F / R to amplify the codon-optimized ABCI sequence, and eGFP-F / R to amplify the eGFP gene fragment. The vector GAPZB is digested with the fast-cutting enzyme EcoRI / KpnI, and the amplified ABCI fragment and eGFP are recovered respectively. The fragment and the digested vector were assembled into a recombinant plasmid GAPZB-ABCI-eGFP by means of multi-fragment assembly. Further, using error-prone PCR, the promoter P on the recombinant plasmid GAPZ-ABCI GAP Carry out random mutation,...

Embodiment 3

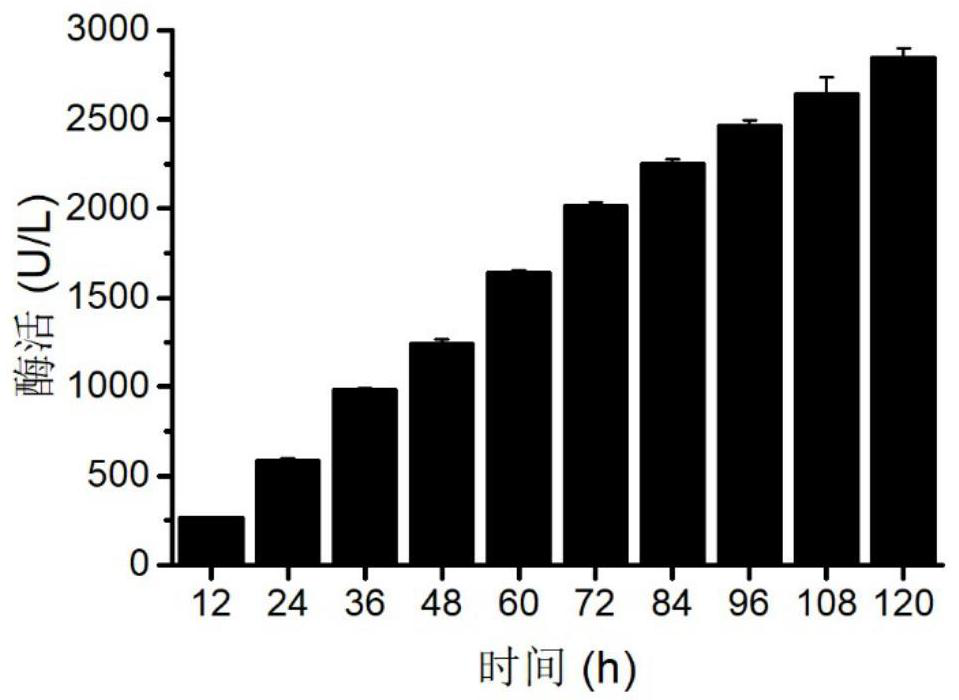

[0039] Embodiment 3: the fermentation culture of recombinant Pichia pastoris S3' in 3-L tank

[0040] With the above-mentioned mutated promoter sequence SEQ ID NO.2, replace the promoter on the secretory expression vector GAPZαB to obtain the plasmid GAPmZαB, construct the GAPmZαB-ABCI plasmid in the same manner as in Example 1, and use the fast cutting enzyme AvrII to linearize the plasmid After transformation into Pichia pastoris GS115, the secreted and expressed recombinant strain S3' was obtained. Pick the recombinant Pichia pastoris S3' strain, inoculate it in 50mL YPD liquid medium, cultivate it at 30°C and 220rpm for 20h, then transfer it to a 3-L fermenter for fermentation at 10% (v / v). The liquid volume is 900mL, the fermentation medium is BSM medium, the initial rotation speed is 200rpm, the fermentation temperature is 30°C, the pH is 5, and the coupling between dissolved oxygen and rotation speed is set to keep the dissolved oxygen greater than 30%. When the strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com