High-temperature steel slag waste heat recovery device

A technology of waste heat recovery device and steel slag, which is applied in the direction of steam engine device, waste heat treatment, energy efficiency improvement, etc., can solve the problems of lack of humanity, low effective utilization of resources, and less use of waste heat, etc., and achieve high resource utilization rate and waste heat utilization High, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

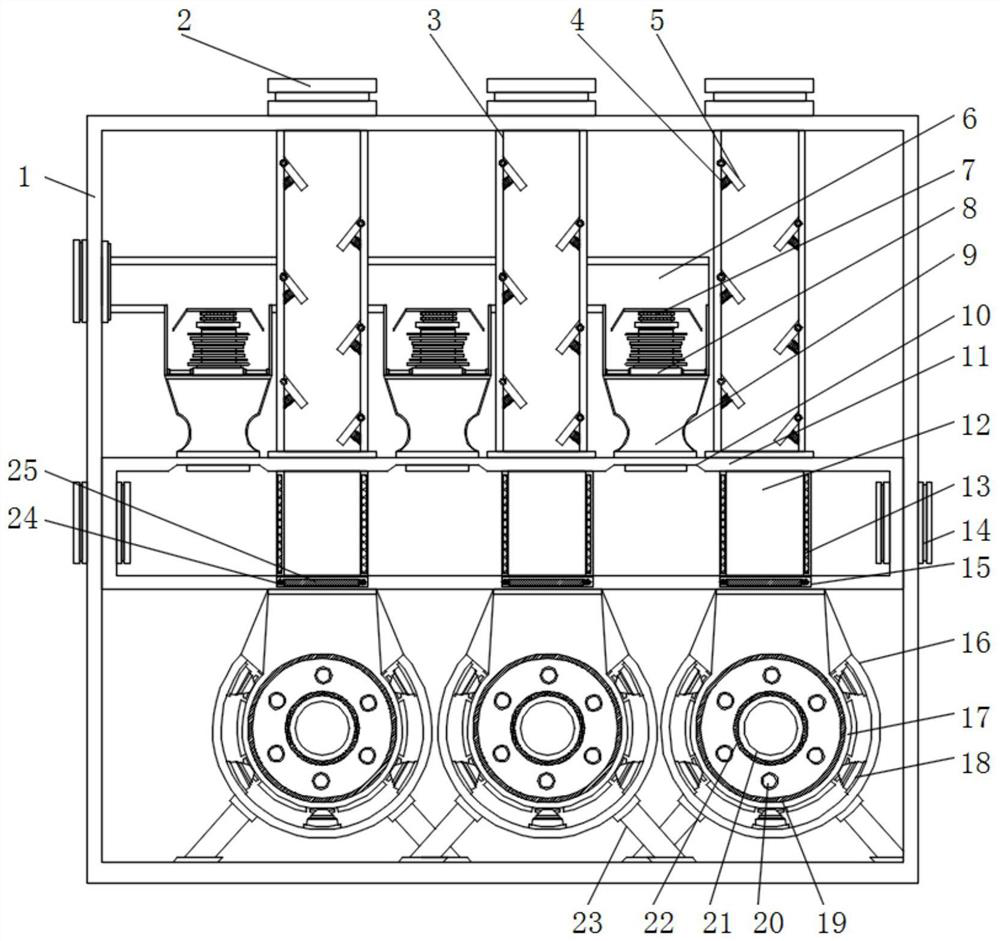

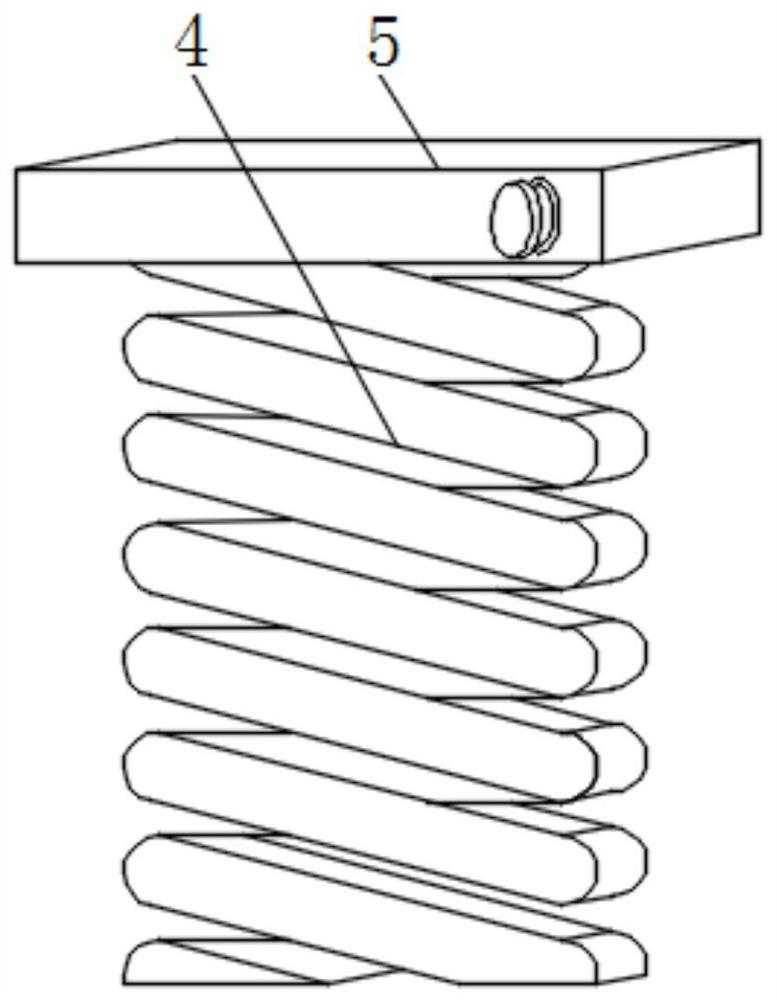

[0036] Embodiment one, with reference to Figure 1-8 , a high-temperature steel slag waste heat recovery device, including a fuselage body 1 and support legs 23, a water tank 11 is fixedly installed in the middle of the fuselage body 1, and several groups of feeding pipes 3 are evenly installed on the top surface of the water tank 11, and the inside of the feeding pipe 3 Several groups of baffle plates 5 are installed on the surface positions of both sides evenly through the rotating shaft, and the middle position of the bottom surface of the baffle plate 5 is fixed with a telescopic spring 4 . Several groups of Laval nozzles 9 are evenly installed between the top surface position and the feeding pipeline 3, and the top surface position of the Laval nozzles 9 is connected with a steam pipeline 6, and a steam turbine 8 is arranged inside the steam pipeline 6, and the top surface position of the steam turbine 8 is A generator 7 is connected, and a sealing mechanism 15 is located...

Embodiment 2

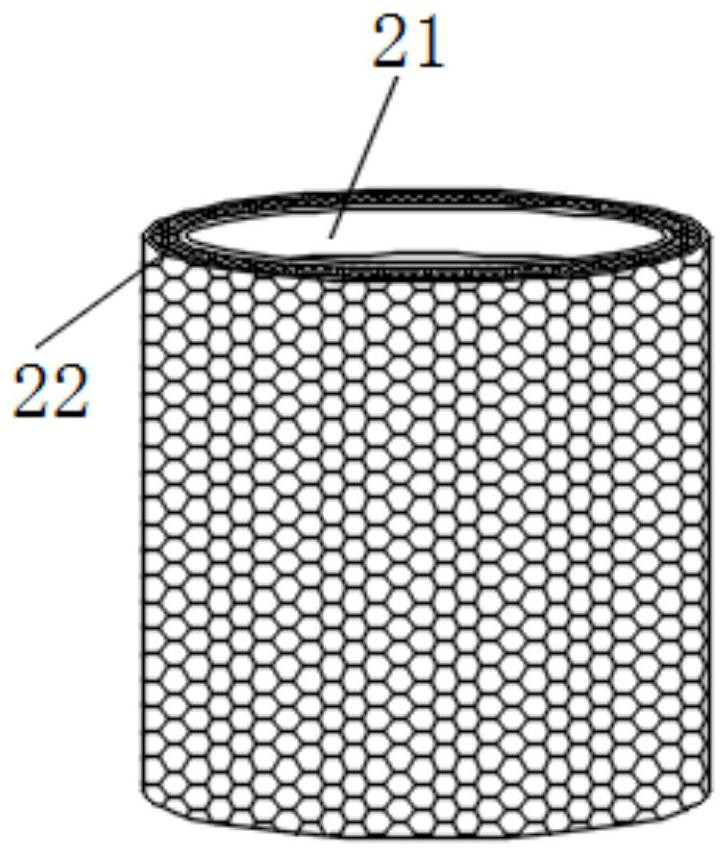

[0037] Embodiment two, refer to figure 1 , image 3 , Figure 4 , Figure 5 and Figure 8 , the position of the bottom surface of the water tank 11 is connected with an arc-shaped groove 16, and several groups of air-jet pipes 18 are evenly installed on the surface of the arc-shaped groove 16. Turntable 19, electric turntable 19 side surface positions are evenly equipped with several component rods 20, electric turntable 19 one side surface middle position is clamped with air outlet pipe 21, air outlet pipe 21 outer periphery is wrapped with filter screen 22, through filter screen 22 can The steel slag is isolated to prevent the steel slag from being discharged through the air outlet pipe 21.

Embodiment 3

[0038] Embodiment three, refer to figure 1 The heat radiation plate 13 is arranged symmetrically in the middle of both sides of the waste heat mechanism 12. The heat generated by the high temperature steel slag can be better absorbed through the heat radiation plate 13, and the effect of waste heat recovery is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com